Pengujian Alat SEM - Scanning Electron Microscope

Summary

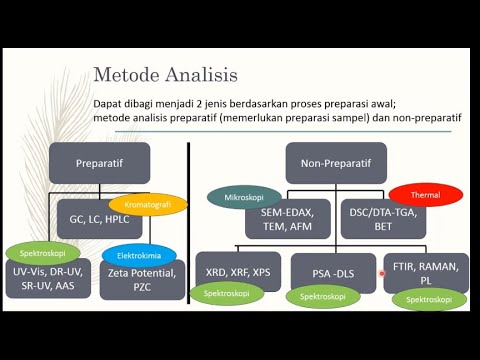

TLDRIn this video, Anjas Prasetiyo provides an in-depth explanation of material characterization using Scanning Electron Microscopy (SEM) in an energy storage research lab. He walks viewers through the SEM process, from preparing samples by coating them with gold to setting up and operating the SEM equipment. The video covers the step-by-step procedure for achieving high-quality imaging, including the use of software for analysis and interpreting particle size and distribution. Anjas also highlights the application of Energy Dispersive X-ray (EDX) analysis for elemental composition. The tutorial concludes with sample results and useful tips for optimal testing.

Takeaways

- 😀 Introduction to the lab facility focused on energy storage and material characterization.

- 😀 The presenter, Anjas Prasetiyo, explains the procedures for conducting a Scanning Electron Microscopy (SEM) test.

- 😀 Preparation of material samples involves coating with gold to enhance conductivity before testing.

- 😀 A vacuum chamber is used to prepare the sample for SEM analysis.

- 😀 The SEM machine used is a Chia brand model JLC.JNE M7008E, capable of various tests including morphology analysis and X-ray mapping.

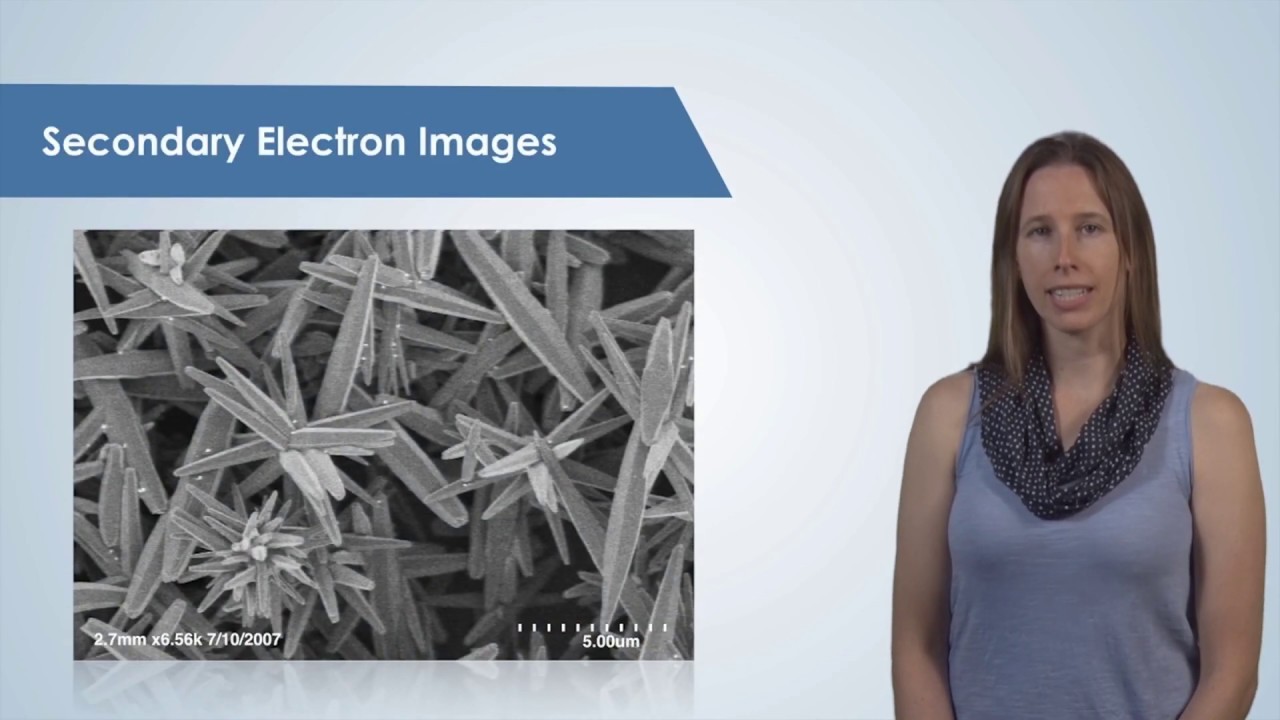

- 😀 SEM analysis allows for particle size measurement and image capturing at up to 1000x magnification.

- 😀 The software used in SEM allows control over focus, brightness, and magnification, with an option for image processing.

- 😀 Detailed steps for preparing the specimen include using tools like carbon tabs, tweezers, and specimen holders.

- 😀 Mapping and elemental analysis can be done using X-ray techniques to identify the distribution of elements in the sample.

- 😀 The SEM software provides data management features for saving and analyzing the collected images and measurements.

Q & A

What is the purpose of using gold coating in SEM testing?

-Gold coating is used to increase the conductivity of the sample, ensuring optimal results when tested under the Scanning Electron Microscope (SEM). It improves the quality of the imaging and analysis, especially for non-conductive materials.

How is the sample prepared before being placed into the SEM?

-The sample is prepared by first placing it on a carbon tab, which helps to secure the sample. Then, it is coated with gold to enhance its conductivity. Finally, the sample is placed into a specimen holder before being inserted into the SEM machine.

What is the function of the 'specimen holder' in SEM testing?

-The specimen holder is used to secure the sample in place within the SEM chamber. It ensures that the sample is positioned correctly for imaging and analysis, and it helps maintain the sample's stability during the test.

What SEM model is being used in the video, and what are its key features?

-The SEM model used in the video is a Child brand, JLC.JNE M7008E. It is capable of performing three key tests: Scanning Electron Microscopy (SEM) for morphology analysis, Energy Dispersive X-ray Spectroscopy (EDX) for elemental analysis, and Mapping for particle distribution.

What are the key parameters for the SEM operation, including voltage and magnification?

-The SEM is operated at a maximum voltage of 15 kV and can provide magnification up to 1000x. These settings allow for high-resolution imaging of the sample's morphology and structure.

What is Energy Dispersive X-ray Spectroscopy (EDX) used for in SEM testing?

-EDX is used to analyze the elemental composition of the sample by detecting the X-rays emitted when the sample is bombarded with an electron beam. This method helps identify the materials present in the sample, such as carbon, oxygen, and aluminum.

How is particle size measurement conducted during SEM testing?

-Particle size measurement in SEM is performed by examining the sample at a specific magnification, such as 1000x, and using tools within the SEM software to measure the size of the particles. Manual measurements can also be taken using the scale provided in the software.

What is the significance of sample vacuuming before SEM imaging?

-Vacuuming the sample chamber removes air and moisture, which can interfere with the electron beam and affect the quality of the imaging and analysis. A vacuum is essential for obtaining clear and accurate results in SEM testing.

What does the SEM software control, and how is it used during testing?

-The SEM software controls various functions such as focusing the sample, adjusting brightness, and capturing images. It also allows users to select testing modes, perform elemental analysis, and analyze the size and distribution of particles in the sample.

How are the results of SEM tests stored and accessed?

-The results of SEM tests are stored in files within the SEM software. These results, including images and analysis data, are saved for later review and can be accessed from the software’s data management section for further processing and analysis.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Introduction to the Scanning Electron Microscope (SEM)

Introduction to Scanning Electron Microscopy (SEM)

Electron Microscopy (TEM and SEM)

1.1 - Introduction to transmission electron microscopy (TEM)

Scanning Electron Microscopy (SEM) | Working Principles and application of SEM in biology

Karakterisasi Material

5.0 / 5 (0 votes)