Van's RV-12 Build: Wings Attachment

Summary

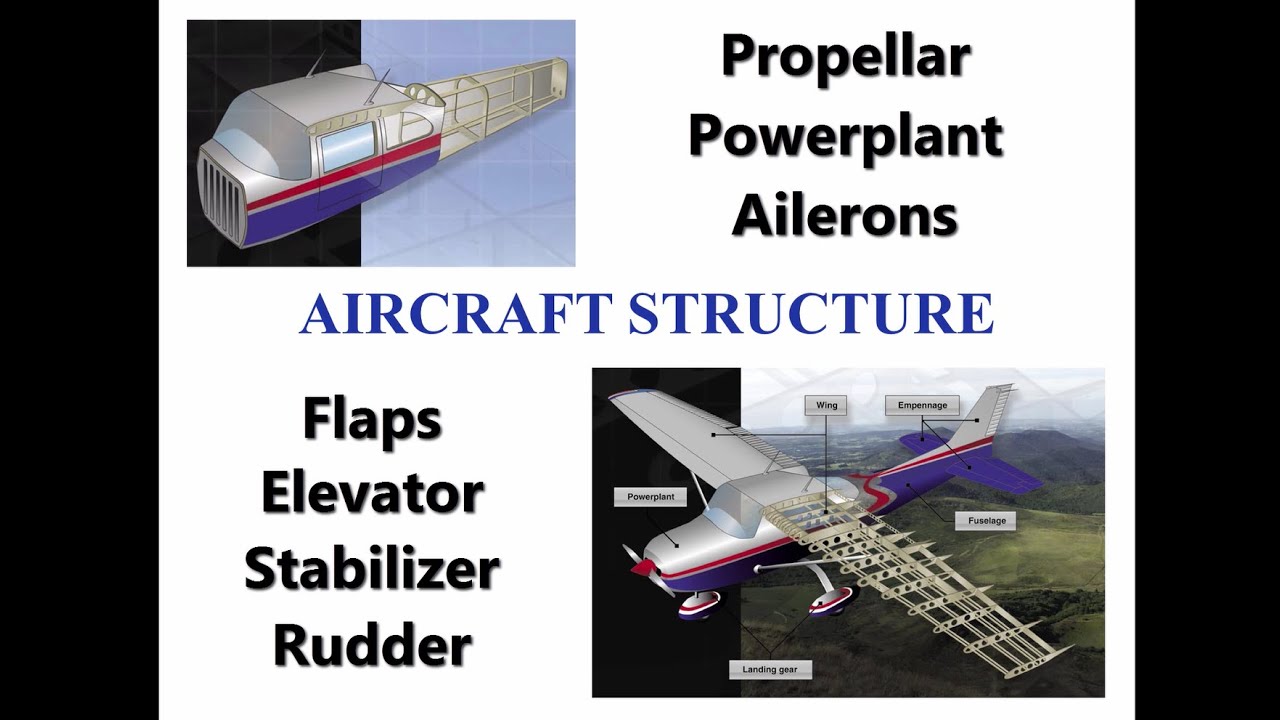

TLDRIn this video, the RV-12 airplane build reaches a major milestone as the wings are successfully attached to the fuselage. The process involved careful maneuvering, precise measurements for gap control, and teamwork between the EAA chapter and students from the Aerospace Academy of Engineering. The wings were mounted securely, with attention paid to the 3/16 inch gap for sealing. Looking ahead, the team will focus on trimming, installing the flapperons, and setting up control linkages. The workspace was also reconfigured to accommodate the larger airplane, marking an exciting step forward in the RV-12's construction.

Takeaways

- 😀 The RV-12’s wings are removable, making it easier to store and transport the airplane.

- 😀 Installing and removing the wings is a two-person job and can be done in 10-15 minutes once familiar with the process.

- 😀 The wings were assembled by students from the Academy of Aerospace and Engineering and fit perfectly when mounted.

- 😀 The fuselage was mounted on saw horses and a table to allow the wings to be rolled underneath for easy attachment.

- 😀 Once the wings are in place, pins are used to secure the wing spars, ensuring they stay in position.

- 😀 The build requires precise gap adjustments between the wing skin and the fuselage skin (3/16 inch gap).

- 😀 The team needs to trim the wing skins and make adjustments to achieve the correct gap before sealing.

- 😀 The flaperons (a combination of flap and aileron) must be mounted, with proper gap measurements taken between the flaperon and fuselage.

- 😀 The control rod for the flaperons will be connected before finalizing the flaperon gap adjustments to ensure full range of motion.

- 😀 The workspace had to be reconfigured after mounting the wings due to the increased space requirements.

- 😀 The next steps in the build include installing the wiring harness and control linkages for the flaperons.

Q & A

What is a unique feature of the RV-12 airplane that is highlighted in the script?

-A unique feature of the RV-12 is its removable wings, which allow for easier storage and transportation. The wings can be taken off and reattached in about 10-15 minutes by two people.

Why is the initial wing fitment not a simple process despite the removable wings feature?

-The initial wing fitment involves careful alignment of the wings and control surfaces. The 27-foot wingspan creates challenges in a tight workspace, making the initial fitment more intricate.

What role did the students of the Aerospace Academy play in the RV-12 build?

-The Aerospace Academy students assembled the wings before they were brought to the hangar. Their precise work allowed the wings to fit perfectly during installation, making the process easier.

How did the team manage to maneuver the wings into place for installation?

-The team used a furniture dolly to roll the left wing underneath the fuselage, as the fuselage was mounted on saw horses and a table, with enough space between the horses to fit the wing.

How are the wings secured to the fuselage once in position?

-The wings are secured by aligning holes in the spars of the wings with bushings on the fuselage, then sliding pins through the holes to lock the spars in place.

What gap needs to be maintained between the wing skin and the fuselage skin, and why is it important?

-A 3/16 inch gap is required between the wing skin and the fuselage skin. This gap is necessary for installing a seal between the two parts, which helps maintain proper aerodynamics and prevent airflow issues.

What is the purpose of the flapperons in the RV-12 build, and how are they mounted?

-The flapperons in the RV-12 function as both flaps and ailerons. They are mounted with bolts in three positions—outboard, middle, and inboard—and need to be adjusted to maintain the proper gap with the fuselage.

Why is it important to wait for the control rod to be connected before trimming the skin around the wings and flapperons?

-Waiting for the control rod to be connected ensures that the team can check the full range of motion of the flapperons. This way, they can ensure the 3/16 inch gap is maintained in all positions before making any cuts.

How did the team adapt their workspace as the build progressed, especially after the wings were installed?

-After installing the wings, the team had to reposition the fuselage and remove parts of the fencing around the workspace. They also had to move workbenches and tables to make room for the expanded wingspan.

What are the next major steps in the RV-12 build following the wing installation?

-The next steps include trimming the wing skins to the proper gap, installing wiring harnesses, and setting up control linkages for the flapperons to ensure full functionality.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahora5.0 / 5 (0 votes)