Drilling machine: Types, Parts, Operations, Working Principle, (Explained in detail)

Summary

TLDRThis video provides a comprehensive guide to drilling machines, detailing their history, parts, and various types. It explores how drilling machines function, the tools involved, and their diverse operations such as drilling, reaming, and tapping. The video covers eight types of drilling machines, from portable to deep hole machines, and emphasizes their role in producing accurate holes in metalworking. Additionally, the video explains key tools like twist drills and core drills, as well as specialized operations like counterboring and lapping. Ideal for anyone interested in machining and engineering processes.

Takeaways

- 😀 Drilling machines are essential in workshops for creating circular holes and are the second most important machine after lathes.

- 😀 The drilling machine's history dates back to 1200 BC when the Egyptians used bow drills to make holes.

- 😀 The main parts of a drilling machine include the base, column, table, radial arm, drill head, chuck, and electric motor.

- 😀 The base supports the column, worktable, and other components, and it can be mounted on a bench or directly on the floor.

- 😀 Drilling machines are classified into eight types: portable, sensitive, upright, radial, gang, multi-spindle, automatic, and deep hole drilling machines.

- 😀 Portable drilling machines are used for small holes and are operated by hand in smaller workshops.

- 😀 Sensitive drilling machines are designed for small, high-speed holes and allow the operator to manually feed the drill for precise control.

- 😀 Radial drilling machines feature a large, movable arm that provides flexibility in drilling at various angles and positions.

- 😀 Gang drilling machines have multiple drill heads placed side by side to drill several holes simultaneously, increasing efficiency.

- 😀 Multi-spindle drilling machines use several spindles to drill multiple holes in one workpiece at the same time.

- 😀 Drilling tools include flat or spade drills, twist drills, taper shank core drills, and center drills, each designed for specific hole-making tasks.

- 😀 Drilling machine operations include drilling, reaming, boring, counterboring, countersinking, spot facing, tapping, lapping, and trapanning to refine and modify holes.

Q & A

What is a drilling machine and what is its primary function?

-A drilling machine is used to create circular holes in solid materials using a cutting tool called a drill bit. It is the second most important machine in a workshop after the lathe machine.

What are the main parts of a drilling machine?

-The main parts of a drilling machine include the base, column, table, table clamp, electric motor, hand wheel, chuck, and drill.

What is the function of the base in a drilling machine?

-The base supports the column and work table, and is made of casting material. It also provides a sturdy foundation for the machine and may be mounted on a bench or the floor.

How does the radial arm in a drilling machine function?

-The radial arm is mounted on the column and extends horizontally over the base. It has guideways on which the drill head slides, allowing the radial arm to move around the column.

What is the significance of the sensitive drilling machine?

-A sensitive drilling machine is designed to drill small holes at high speeds with manual control. The operator senses the cutting action, which allows for better control and prevents damage to the drill bit.

How does the gang drilling machine differ from other types of drilling machines?

-A gang drilling machine consists of multiple drill heads placed side by side, enabling it to drill multiple holes at the same time on the same or different workpieces, increasing production speed.

What types of materials are typically drilled using a twist drill?

-A twist drill is the most commonly used type of drill for a wide range of materials, including metals, wood, and plastics. It is designed with spiral grooves to efficiently remove chips during drilling.

What is reaming, and when is it performed?

-Reaming is a process used to size and finish a hole that has already been drilled. It is performed to achieve an accurate hole size and smooth finish, typically using a ream tool with multiple cutting edges.

What is the purpose of counterboring in drilling operations?

-Counterboring enlarges the end of a hole to create a square shoulder. This operation is necessary for accommodating the heads of bolts, studs, or pins.

What distinguishes a multi-spindle drilling machine from a standard drilling machine?

-A multi-spindle drilling machine features several spindles driven by a single motor, allowing it to drill multiple holes simultaneously in a workpiece, improving efficiency in mass production.

Can you explain what tapping operation involves in a drilling machine?

-Tapping is the process of cutting internal threads within a hole using a tool called a tap. It is performed either manually or automatically and is used to create threaded holes for screws or bolts.

What is the purpose of the tapping operation in a drilling machine?

-Tapping is used to cut internal threads inside a hole, which are necessary for fastening purposes, such as screws or bolts. The tap is a specially designed tool with hardened and ground threads that act as cutting edges.

How does a deep hole drilling machine work?

-A deep hole drilling machine is designed for drilling long, deep holes. The workpiece is rotated, while the stationary drill bit creates the hole, typically used for drilling components like rifle barrels and crankshafts.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Which WEAPON Is Right For YOU In 2024? All Weapons Overview | Albion Weapon Guide 2024

Schroeven

Pengenalan Well Logging

Types of Drill jigs & Requirement of Drill jig ||Engineer's Academy||

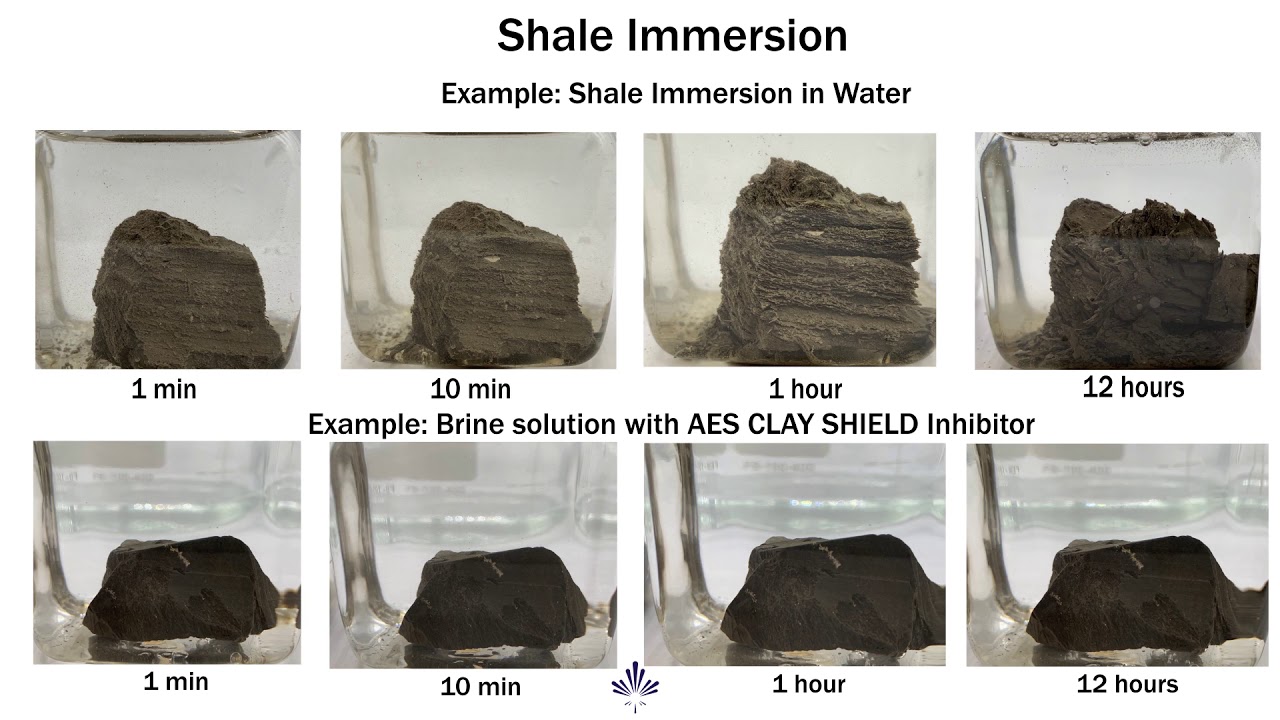

AES Tech Tip 3: Shale Inhibition and Testing

MESIN BUBUT - DEFINISI, CARA KERJA, JENIS-JENIS DAN BAGIAN-BAGIAN MESIN BUBUT

5.0 / 5 (0 votes)