Hydraulic Training Series - Chapter 3 - Actuators

Summary

TLDRThis video provides a comprehensive introduction to hydraulic actuators, explaining their role in converting hydraulic energy into mechanical motion. It covers the different types of hydraulic cylinders, such as single-acting, double-acting, and telescoping, and their applications. The video also explores hydraulic motors, including fixed and variable displacement motors, and their use in rotary motion systems. Key concepts like force, torque, speed, and efficiency are discussed, along with various motor types, including gear, vane, and piston motors. The video concludes by highlighting the importance of hydraulic actuators in diverse industries, showcasing their versatility in performing both linear and rotary tasks.

Takeaways

- 😀 Hydraulic actuators are essential components in hydraulic systems, converting hydraulic energy into mechanical energy to perform work.

- 😀 A hydraulic cylinder is used for linear motion, while a hydraulic motor is used for rotary motion.

- 😀 Single-acting cylinders are powered hydraulically in one direction and are returned by gravity or external force, such as in forklift trucks.

- 😀 Telescoping cylinders are a type of single-acting cylinder that allows long extension in a compact space, useful in applications like dump trucks.

- 😀 Double-acting cylinders have two power directions and allow for greater force and control in both extension and retraction, with speed differences due to the rod's displacement.

- 😀 The speed of a cylinder is affected by the area difference between the cap end and the rod side. A larger area on the cap end allows for greater force but slower extension.

- 😀 Double-acting cylinders can have additional features like rod wipers, air vents, cushions, and stop tubes to enhance performance and prevent wear.

- 😀 Hydraulic motors, including fixed and variable displacement types, convert hydraulic fluid flow into rotational motion and torque.

- 😀 Torque in hydraulic motors is defined as force times radius, and motor size and displacement determine speed and torque output.

- 😀 Vane motors and piston motors offer different advantages in terms of pressure, speed, and efficiency, with piston motors typically providing higher performance at higher pressures.

- 😀 Piston-type motors have more precise control over torque and speed, with inline and bent axis configurations offering different operational benefits, especially in high-pressure systems.

Q & A

What is the primary function of a hydraulic actuator?

-The primary function of a hydraulic actuator is to convert hydraulic energy into mechanical motion, either in linear or rotary form, to perform useful work in a hydraulic system.

What are the two main types of hydraulic actuators?

-The two main types of hydraulic actuators are hydraulic cylinders, which provide linear motion, and hydraulic motors, which provide rotary motion.

What distinguishes a single-acting hydraulic cylinder from a double-acting hydraulic cylinder?

-A single-acting hydraulic cylinder powers motion in one direction and is returned by gravity or an external force, while a double-acting hydraulic cylinder uses hydraulic power in both directions, providing force and motion for both extension and retraction.

What is the main advantage of a telescoping hydraulic cylinder?

-A telescoping hydraulic cylinder allows for a very long extension while maintaining a compact stored length, making it ideal for applications like dump trucks where space-saving is essential.

How does the force and speed of a double-acting hydraulic cylinder differ during extension and retraction?

-The force exerted during extension is greater because the cap end of the cylinder has a larger area compared to the rod side, while retraction is faster due to the smaller volume of oil needed to fill the rod side.

What are the key components and features of a hydraulic motor?

-A hydraulic motor consists of a housing, gears, veins, or pistons that convert hydraulic pressure into rotary motion. Key features include fixed or variable displacement, and they can vary in size, torque, and speed based on design and application.

What are the differences between fixed and variable displacement hydraulic motors?

-A fixed displacement hydraulic motor operates at a constant speed and torque, whereas a variable displacement motor can adjust its displacement, changing speed and torque capabilities based on the system's requirements.

How is torque generated in a gear-type hydraulic motor?

-Torque in a gear-type hydraulic motor is generated by the pressure applied to the gear teeth, causing them to rotate. However, some gear teeth cancel out the torque due to equal pressure on opposite sides, limiting the effective torque produced.

What role do rod wipers and air vents play in a hydraulic cylinder?

-Rod wipers remove dirt and debris from the cylinder rod to prevent contamination, while air vents allow air to escape from the cylinder, preventing erratic operation and ensuring smooth functionality.

How does a vane motor differ in construction from a vane pump?

-The main difference between a vane motor and a vane pump is that a vane motor must have a mechanism, such as springs or pressurized oil, to hold the veins out against the cam ring, allowing it to generate torque, whereas a vane pump does not require this mechanism.

What is the significance of swashplate angle in a piston-type hydraulic motor?

-In a piston-type hydraulic motor, the angle of the swashplate determines the stroke length of the pistons, affecting both torque and speed. A larger angle results in higher torque but lower speed, while a smaller angle leads to lower torque and higher speed.

Why are radial piston motors used in low-speed, high-torque applications?

-Radial piston motors are designed for low-speed, high-torque applications due to their compact, efficient design and their ability to handle high pressures, making them suitable for heavy-duty applications such as mobile vehicle drives and mining machinery.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

HYDRAULIC ACTUATORS VICKERS HYDRAULIC TRAINING VEDIO BY MR PAUL COOK

Modul 3 subtopik 3.1. pengertian sistem hidrolik

Hydraulic Actuators & Motors - Hydraulics - Airframes & Aircraft Systems #9

#2 Komponen dan Alat Pendukung IoT 1 (Komponen Dasar Elektronika, Sensor dan Aktuator)

What is an Actuator?

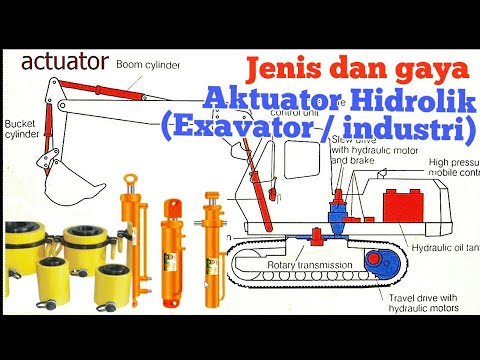

HLP10⚛Hidrolik Actuator merubah energi hidrolik jadi Mekanik sesuai gaya kerjanya

5.0 / 5 (0 votes)