HYDRAULIC ACTUATORS VICKERS HYDRAULIC TRAINING VEDIO BY MR PAUL COOK

Summary

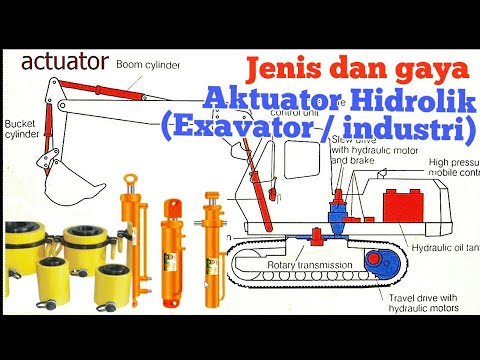

TLDRThis video provides an in-depth overview of hydraulic actuators, focusing on their function in converting hydraulic energy into mechanical work. It explains various types, including single and double acting cylinders, as well as hydraulic motors, detailing their applications in equipment like forklifts and dump trucks. Key concepts such as force, torque, and pressure are discussed, highlighting their significance in determining actuator performance. The presentation emphasizes the versatility of hydraulic systems in industrial settings, illustrating how they facilitate both linear and rotary motion, ultimately enhancing operational efficiency.

Takeaways

- 😀 Hydraulic actuators convert hydraulic energy into mechanical energy, crucial for performing work.

- 🚜 Single acting cylinders operate in one direction and return using gravity or external forces.

- 🔄 Telescoping cylinders provide long extensions while occupying minimal space, ideal for applications like dump trucks.

- 💧 Double acting cylinders operate in both directions, with oil directed to either end to control movement.

- ⚖️ The force of a cylinder is determined by its effective area and hydraulic pressure, affecting extension and retraction speeds.

- 📦 Common applications for hydraulic cylinders include clamping, conveyors, chemical mixers, and injection molders.

- ⚙️ Fixed displacement hydraulic motors provide constant speed and torque, while variable displacement motors allow for adjustments.

- 🔩 Piston motors can handle higher pressures and speeds, with performance influenced by the swash plate angle.

- 🛠️ Bent axis and radial piston motors are designed for high torque and low-speed applications, such as in injection molding machines.

- 🔄 Hydraulic actuators are essential for converting hydraulic energy back into mechanical work in various industrial systems.

Q & A

What is the primary function of hydraulic actuators?

-Hydraulic actuators convert hydraulic energy back into mechanical energy to perform useful work.

What are the two main types of hydraulic actuators discussed in the script?

-The two main types are hydraulic cylinders and hydraulic motors.

What distinguishes a single-acting cylinder from a double-acting cylinder?

-A single-acting cylinder uses hydraulic power to operate in one direction and returns by gravity or an external force, while a double-acting cylinder can operate in both directions using hydraulic pressure.

What is a telescoping cylinder and its typical application?

-A telescoping cylinder is designed for long extensions while maintaining a compact size, commonly used in dump trucks to raise and lower containers.

How does the effective area of a hydraulic cylinder influence its force and speed?

-The effective area determines the force exerted (force = pressure × area), and a larger area can lead to a higher force but may also affect the speed of extension and retraction.

What are the characteristics of fixed displacement and variable displacement motors?

-Fixed displacement motors provide a constant flow and speed, while variable displacement motors allow for adjustable flow rates, changing the speed and torque based on application requirements.

How is torque calculated in hydraulic motors?

-Torque in hydraulic motors is calculated as torque = force × radius arm, where the force is the hydraulic pressure acting on the motor.

What role do rod wipers and air vents play in hydraulic cylinders?

-Rod wipers prevent dirt accumulation on the rod, while air vents allow trapped air to escape from the cylinder, ensuring smooth operation.

What is the significance of piston motors in hydraulic systems?

-Piston motors typically allow for higher pressures and speeds compared to gear or vane motors, making them suitable for demanding applications.

What does the angle of displacement in a piston motor affect?

-The angle of displacement determines the stroke length of the pistons and consequently influences the torque and speed capabilities of the motor.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Hydraulic Training Series - Chapter 3 - Actuators

Modul 3 subtopik 3.1. pengertian sistem hidrolik

HLP10⚛Hidrolik Actuator merubah energi hidrolik jadi Mekanik sesuai gaya kerjanya

Mengenal Simbol Hidrolik dan Benda aslinya #waginothok

#2 Komponen dan Alat Pendukung IoT 1 (Komponen Dasar Elektronika, Sensor dan Aktuator)

Hydraulic Actuators & Motors - Hydraulics - Airframes & Aircraft Systems #9

5.0 / 5 (0 votes)