Gear Boxes & Accessory Drives - Aircraft Gas Turbine Engines #16

Summary

TLDRThe accessory gearbox in aircraft engines is vital for driving hydraulic, pneumatic, and electrical systems, including fuel and oil pumps. It typically connects to the high-pressure compressor shaft, with modern turbofan designs allowing for efficient accessory placement. Challenges arise from axial movement of the compressor shaft, addressed by using splined shafts or idler gears to maintain drive engagement. Accessory gearboxes often feature a shear neck for safety, allowing individual component failures without total gearbox loss, although critical components lack this feature. Overall, these systems ensure reliable engine operation while accommodating space and load distribution.

Takeaways

- 🔧 The accessory gearbox powers hydraulic, pneumatic, and electrical systems necessary for engine and aircraft operation.

- 💡 It drives fuel pumps, oil pumps, tachometers, and other devices essential for efficient engine performance.

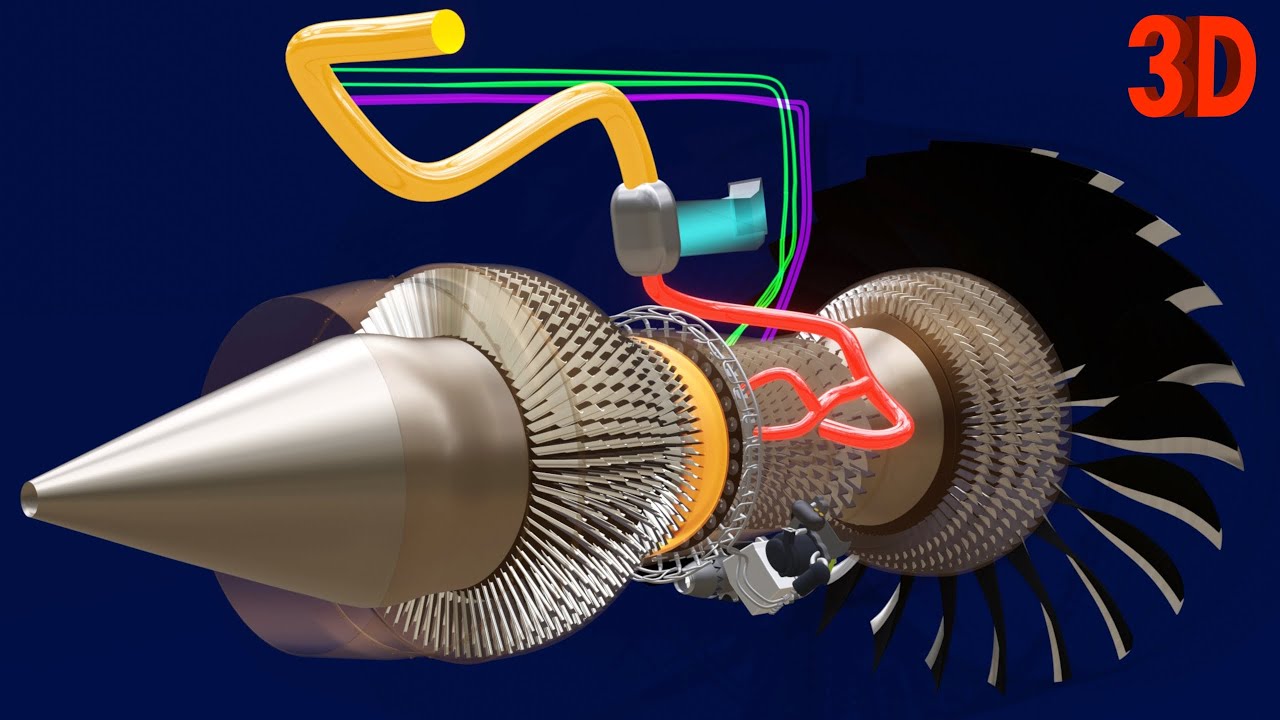

- ⚙️ The drive for the accessory gearbox is typically taken from the high-pressure compressor shaft via an internal gearbox.

- 📉 Axial movement of the compressor shaft is managed to prevent damage to bevel gears, which can occur during engine operation.

- 🔄 A splined shaft design allows for axial movement without disconnecting the gear teeth, maintaining reliable drive.

- 🔄 An alternative design utilizes an idler gear shaft to accommodate axial movement while transferring drive between shafts.

- 🛠️ Some engines feature a dual gearbox system, dividing the load and accommodating space constraints around the engine.

- 🔋 The starter motor, mounted on the accessory gearbox, reverses the drive situation to start the engine.

- 📏 Accessory gearboxes are shaped for easy access during servicing and are often located on the underside of the engine.

- ⚠️ Shear necks are incorporated into drive shafts as a safety measure, allowing individual component failures without affecting the whole gearbox.

Q & A

What is the primary function of the accessory gearbox in an aircraft engine?

-The accessory gearbox provides power to hydraulic, pneumatic, and electrical systems used in both the engine and the aircraft.

How does the accessory gearbox get its drive?

-The drive for the accessory gearbox is typically taken from the high-pressure compressor shaft via an internal gearbox, which then passes to an external gearbox.

What kind of accessories are commonly driven by the accessory gearbox?

-Common accessories driven by the gearbox include fuel pumps, oil pumps, tachogenerators, and various other devices necessary for efficient engine operation.

What problem arises from the axial movement of the compressor shaft, and how is it addressed?

-Axial movement can cause the teeth of the bevel gears to move apart, interrupting the drive. This is addressed by designing the gears so that they remain engaged despite the axial movement.

What is a shear neck, and what is its purpose in the accessory gearbox?

-A shear neck is a weaker section machined into the drive shaft that is designed to fail under excessive load, allowing the failure of an individual component without affecting the overall gearbox operation.

How are the accessory gearboxes arranged in modern turbofan engines compared to older designs?

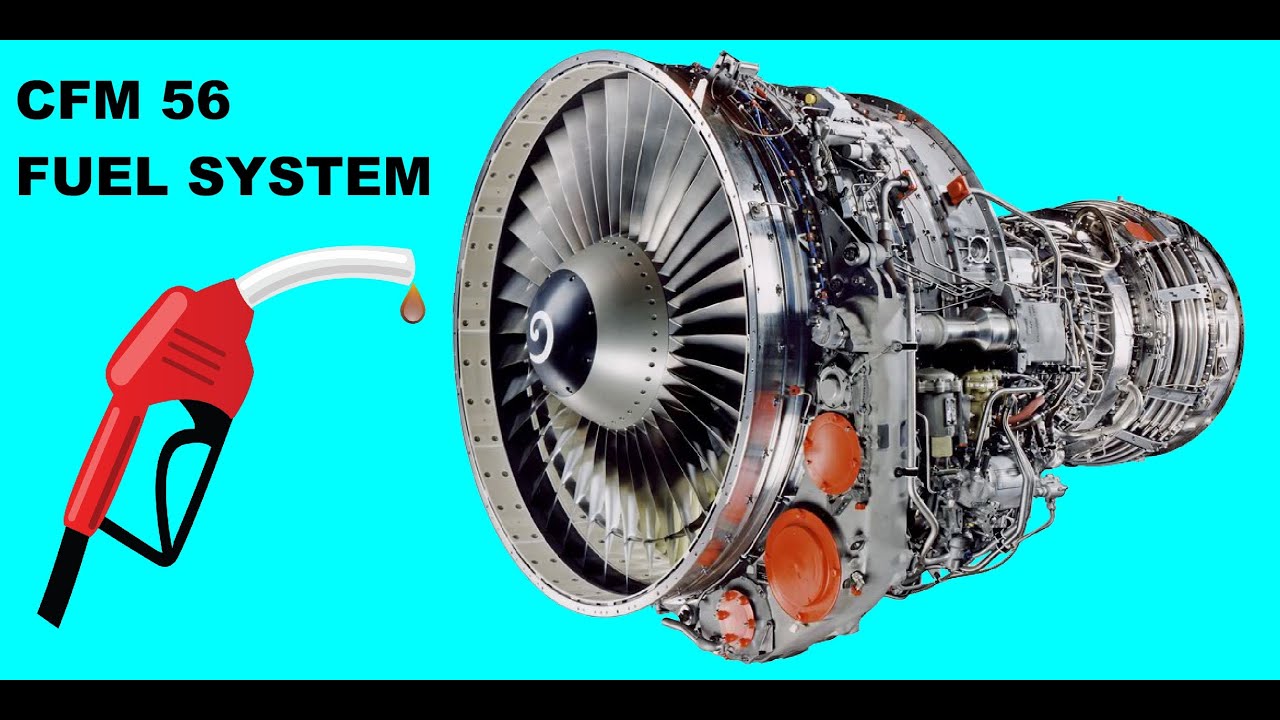

-Modern turbofan engines typically have larger accessory gearboxes that can accommodate various accessories beneath the cowling, reducing the issues of limited space faced by older, slimmer engine designs.

What happens to the gearbox's operation during engine start?

-During engine start, the gearbox is driven by the starter motor, causing the high-pressure compressor shaft to rotate, which subsequently rotates the low-pressure compressor shaft through airflow.

Why is it advantageous to have two smaller accessory gearboxes?

-Dividing the accessory gearbox into two smaller units helps in spreading the load and managing space constraints, making it easier to fit the gearbox around the engine.

What is the classification of the gearbox driven by the high-pressure compressor shaft?

-The gearbox driven by the high-pressure compressor shaft is classified as the high-speed external gearbox, while the one driven by the low-pressure compressor shaft is termed the low-speed external gearbox.

What features ensure efficient load distribution within the accessory gearbox?

-The gearbox incorporates a combination of wide and thin gear teeth, allowing for efficient load distribution while minimizing the overall weight of the gearbox.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

5.0 / 5 (0 votes)