Layout dan Proses Produksi Eps 5

Summary

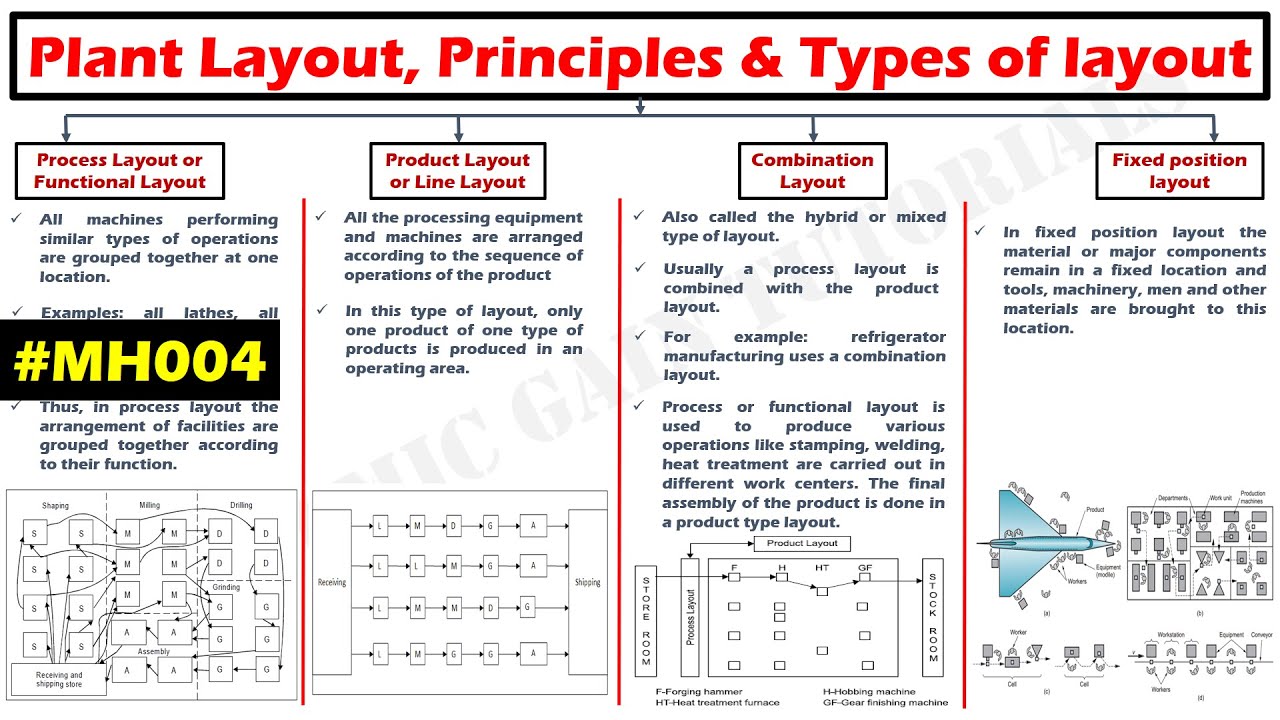

TLDRThe video script discusses the advantages and disadvantages of two production layouts: product layout and job shop layout. Product layout benefits include high production volume, low per-unit costs, and minimal training requirements due to the specific workforce needed. However, it faces challenges such as repetitive tasks leading to low morale and limited flexibility. In contrast, job shop layout is suited for low-volume, diverse production, offering flexibility and skilled labor. It ensures continuity with backup equipment and lower costs for multi-use equipment. The script emphasizes the importance of choosing the right layout based on production needs.

Takeaways

- 📈 High production volumes in product layout lead to lower costs per unit.

- 👷♂️ Specialized labor in product layout minimizes training needs for workers.

- 💰 Lower material procurement costs are a benefit of product layout.

- 🔧 Optimized use of labor and equipment enhances efficiency in production.

- 📝 Established production plans reduce the need for extensive system oversight.

- 📊 Regular monitoring of purchasing and inventory is possible with product layout.

- 😟 Repetitive tasks in product layout can negatively impact worker morale and development.

- ⚙️ Low-skilled labor can lead to inadequate maintenance and lower product quality.

- 🔄 Job shop layout is suitable for low production volumes with diverse products.

- 🔍 Job shop layout offers high flexibility and requires skilled labor for effective operation.

Q & A

What are the advantages of using a product layout?

-The advantages include high production volume, low cost per unit due to high production levels, minimal training needed for specific labor, low material procurement costs, optimized use of labor and equipment, and established production plans that reduce oversight needs.

What are the disadvantages of a product layout?

-The disadvantages include repetitive tasks that limit employee development opportunities, low skill levels leading to poor maintenance and product quality, lack of responsiveness to changes in product capacity and design, vulnerability to disruptions from equipment failures, and increased costs for maintenance and spare parts.

What type of production process does a job shop layout utilize?

-A job shop layout typically uses a discontinuous or intermittent production process, which is chosen for low production volumes with a variety of products.

Why is flexibility important in a job shop layout?

-Flexibility is important because the equipment is designed to handle diverse products, allowing the production system to adapt to varying customer demands.

What kind of workforce is needed for effective operation in a job shop layout?

-A highly skilled workforce is required to operate the equipment optimally and ensure high-quality production.

How is equipment arranged in a job shop layout?

-In a job shop layout, similar equipment is grouped together in specific areas, which supports high-skilled labor and helps maintain production continuity.

What is a key benefit of having backup equipment in a job shop layout?

-Having backup equipment ensures that production can continue smoothly when primary equipment fails or is under maintenance.

What are some benefits of a process layout compared to other layouts?

-Benefits include high flexibility to process various product variations, reduced likelihood of system interruptions, lower equipment costs due to multi-use equipment, and the ability to implement individual incentive systems.

What is meant by 'intermittent production'?

-Intermittent production refers to a production system where processes are not continuous, allowing for different product types to be produced as needed, which contrasts with continuous production systems.

How can employee morale be affected in a product layout?

-Employee morale can suffer due to the repetitive nature of tasks and the lack of opportunities for personal and professional development.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Lec 19: Plant Layout: Types of Layout

02_06_P1 Three Types of Layouts: Process, Product, and Fixed Position

#MH004 Plant Layout, Principles of plant layout & Types of layout.

Plant Layout, Objectives of Plant Layout, Types of Plant Layout [Animated video]

Types of Plant Layout, Explanation with Advantages and Dis-advantages, Plant layout part 2

(PART 13) - MEMBUAT PLANOGRAM : 2. Membuat Layout Retail : Tujuan, Manfaat dan Jenis Layout

5.0 / 5 (0 votes)