Anatomy of a Baghouse

Summary

TLDRThis video provides an overview of the components and operation of a baghouse-style dust collector, focusing on a TubeJet model. The system removes particulates from the air by drawing dust-laden air through filter bags supported by metal cages. A pulse-jet cleaning system periodically dislodges dust from the bags, which then falls into hoppers. Various types of discharge equipment, like rotary airlock valves or screw conveyors, remove the dust from the hoppers. The video also discusses different configurations for bag replacement, depending on the baghouse's design and available space.

Takeaways

- 🛠️ Baghouses are designed to remove particulates from the air and come in various types and shapes, but work similarly.

- 💨 Incoming dust-laden air is moved through the baghouse by fan power, either pushed in by a forced draft fan or pulled out by an induced draft fan.

- 🔧 Inside the baghouse, metal cages support long filter bags, which act as the primary filtration medium.

- 🧹 Dust particles are captured on the exterior surface of these filter bags as air passes through them.

- 📏 The filter bags, resembling tube socks, are designed with specific media to suit various dust collection applications.

- ⚙️ The dust collected on the bags is periodically removed using a pulse-jet cleaning system, ensuring continuous efficiency.

- 📊 Pulse jet cleaning can be activated either on a timed sequence or based on differential pressure readings (on-demand cleaning).

- 🔄 During cleaning, compressed air is sent in reverse through the bags to dislodge accumulated dust, which then falls into hoppers.

- 🔩 Hoppers below the bags collect the dust and can be fitted with discharge equipment like rotary airlock valves or screw conveyors.

- 🏗️ TubeJet baghouses come in square or cylindrical shapes, with flexible options for replacing filter bags from the top, side, or bottom.

Q & A

What is a baghouse-style dust collector?

-A baghouse-style dust collector is a system used to remove particulates from the air by drawing dust-laden air through filter bags, which trap the dust and allow clean air to pass through.

How does a baghouse system work to clean air?

-Dirty air is either pushed or pulled into the baghouse, where it passes through filter bags that trap dust particles on the surface. The clean air then moves downstream into the stack or recirculates into the process.

What are the main components of a baghouse dust collector?

-Key components include the fan (which draws air in), the clean air plenum, the filter bags supported by metal cages, a pulse-jet cleaning system, and hoppers to collect the dust.

What is the purpose of the pulse-jet cleaning system?

-The pulse-jet cleaning system removes dust buildup from the filter bags by sending a reverse flow of compressed air through the bags, which dislodges the dust into hoppers below.

What are filter bags, and what do they do?

-Filter bags are long, tube-like structures made from specific media designed to trap dust particles on their surface. They filter the air by allowing clean air to pass through while trapping particulates on the outside.

What happens to the dust after it is dislodged from the filter bags?

-Once dislodged, the dust falls into hoppers located beneath the bags. These hoppers can be designed as pyramidal or trough shapes, depending on the system.

How is dust removed from the hopper in a baghouse system?

-Dust is typically removed from pyramidal hoppers using rotary airlock valves or slide gates, while trough hoppers use screw conveyors coupled with rotary airlocks.

What are the differences between positive and negative baghouse systems?

-In a positive system, air is pushed into the baghouse by a forced draft fan at the inlet. In a negative system, air is pulled from the baghouse by an induced draft fan at the outlet.

What are the two basic shapes of TubeJet baghouse systems?

-TubeJet baghouse systems come in two basic shapes: square and cylindrical.

How are filter bags replaced in different TubeJet baghouse designs?

-In square TubeJet designs, filter bags can be replaced from the top through a hatch or a walk-in clean air plenum. Cylindrical designs typically feature a lift-off head for top access or can be configured for side or bottom removal.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Parameter Transistor Alfa Beta | Kuliah Fisika Semikonduktor

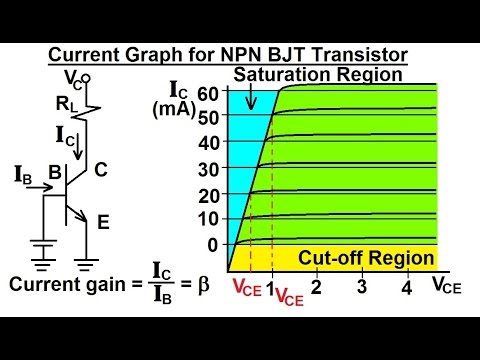

Electrical Engineering: Ch 3: Circuit Analysis (28 of 37) Current Graph for NPN BJT Transistor

Automotive Electrical System Basics - EricTheCarGuy

PLTU (Pusat Listrik Tenaga Uap) - Prinsip Kerja, Kelebihan dan Kekurangan

HiKOKI新型36V集塵丸ノコC3605DYB(125mm)の集塵能力は?マキタの18VのKS511Dと比較

Airbus A320 CBT # 30 ELECTRICAL POWER SYSTEM PRESENTATION

5.0 / 5 (0 votes)