Gerinda dan Proses Abrasif Lainnya

Summary

TLDRThis video, presented by Aron Bagus Jagat Dewantoro, explores the various types of grinding and abrasive processes used in machining. It covers the fundamentals of grinding, including the types of grinding machines and their components, as well as other abrasive processes like honing, lapping, polishing, and buffing. The video highlights the importance of abrasive processes in achieving high precision, surface quality, and efficient large-scale production. It also touches on specialized applications such as in the automotive, optical, and electronics industries, emphasizing their crucial role in modern manufacturing.

Takeaways

- 😀 Grinding is a non-conventional machining process that uses a grinding stone with abrasive particles and a binding material to cut a workpiece.

- 😀 The main purposes of grinding are to smooth the workpiece surface, achieve high precision size and shape, sharpen cutting tools, and remove traces of previous processes.

- 😀 Different types of grinding machines include hand grinders, flat grinders, cylindrical grinders, and cutting tool grinders, each serving specific functions.

- 😀 Grinding stones consist of abrasive materials like aluminum oxide, silicon carbide, 3D boronite, and diamonds, as well as binding materials such as ceramic, resin, and metal.

- 😀 Honing is an abrasive process used to polish the inner surface of a cylindrical hole, improving geometry, hardness, and smoothness, with common applications in engine cylinders.

- 😀 Lapping is an abrasive process that uses abrasive pellets, granules, and lubricating fluid to achieve flat and smooth surfaces, often for optical mirrors, semiconductor manufacturing, and precision parts.

- 😀 Polishing involves using small abrasive materials on cloth or soft materials to create a smooth or shiny surface, commonly used for aesthetics and reducing friction.

- 😀 Buffing, similar to polishing, focuses on achieving a high surface shine with the use of a paste or buffing compound, typically applied after polishing.

- 😀 Other abrasive processes include flow machining abrasion, super finishing, and sunblasting, which serve specialized functions like smoothing hard-to-reach areas and cleaning surfaces before coating.

- 😀 Abrasive processes are critical for achieving high precision, improving surface quality, processing hard materials, controlling material removal, supporting large-scale production, and ensuring special applications like in optics and electronics.

Q & A

What is the grinding process?

-Grinding is the process of cutting a workpiece using a cutting tool in the form of a grinding stone, which consists of hard abrasive particles and a binding material. It falls under non-conventional machining as it uses high frictional forces to remove material.

What are the primary functions and purposes of the grinding process?

-The main functions of grinding include smoothing the surface of a workpiece, achieving high precision size and shape, sharpening cutting tools (such as chisels, lathes, and drill bits), and removing traces of previous machining processes (like lathing and milling).

What are the types of grinding machines?

-The types of grinding machines include hand grinders (for flexible light jobs), flat grinders (for smoothing flat surfaces), cylindrical grinders (for grinding the outer or inner diameter of a cylinder), bench grinders (for sharpening cutting tools), and cutting tool grinders (for sharpening specific cutting tools).

What materials are used in grinding stones?

-Grinding stones consist of abrasive materials such as aluminum oxide, silicon carbide, 3D boronite, and diamonds. The binding materials include ceramic, resin, and metal, while pores (empty spaces) between the abrasives help with cooling and dust removal.

What is the purpose of honing in the abrasive process?

-Honing is a polishing process using small abrasive stones moved back and forth in a cylindrical hole. It improves the geometry and hardness of the inner surface, increasing the accuracy of the diameter and smoothness of the hole. It is commonly applied to cylinder bores in internal combustion engines.

How does lapping differ from other abrasive processes?

-Lapping is an abrasive process using abrasive pellets, plastic granules, or abrasive granules combined with lubricating fluid between two surfaces. It produces very flat and smooth surfaces and is used for high dimensional tolerance and flatness, typically in optical mirrors, semiconductors, and precision cards.

What is the difference between polishing and buffing?

-Polishing is a fine abrasion process using very small abrasive materials attached to a cloth wheel or soft material to produce a smooth or shiny surface. Buffing, while similar to polishing, focuses on achieving a high surface shine with the help of a paste or buffing compound, usually applied after polishing.

What is flow machining abrasion, and where is it used?

-Flow machining abrasion is a non-conventional abrasive process that uses abrasive fluid flowing through a narrow surface or channel to smooth the inner surface. It is suitable for hard-to-reach surfaces, internal channels, and complex components.

What are the benefits of super finishing in the abrasive process?

-Super finishing is an advanced grinding or honing process that uses low pressure and low speed to smooth the surface. This reduces microscopic peaks, improving the component's life and performance. It is commonly used for crankshafts, bearings, and hydraulic components.

Why is the abrasive process crucial in various industries?

-The abrasive process is crucial because it provides high precision, improves surface quality, enables the processing of hard materials, ensures precise material removal, and supports efficient large-scale production. It is also used in specialized applications such as optical and electronics manufacturing and surface preparation before painting.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Electrochemical Grinding Process | How electrochemical grinding works

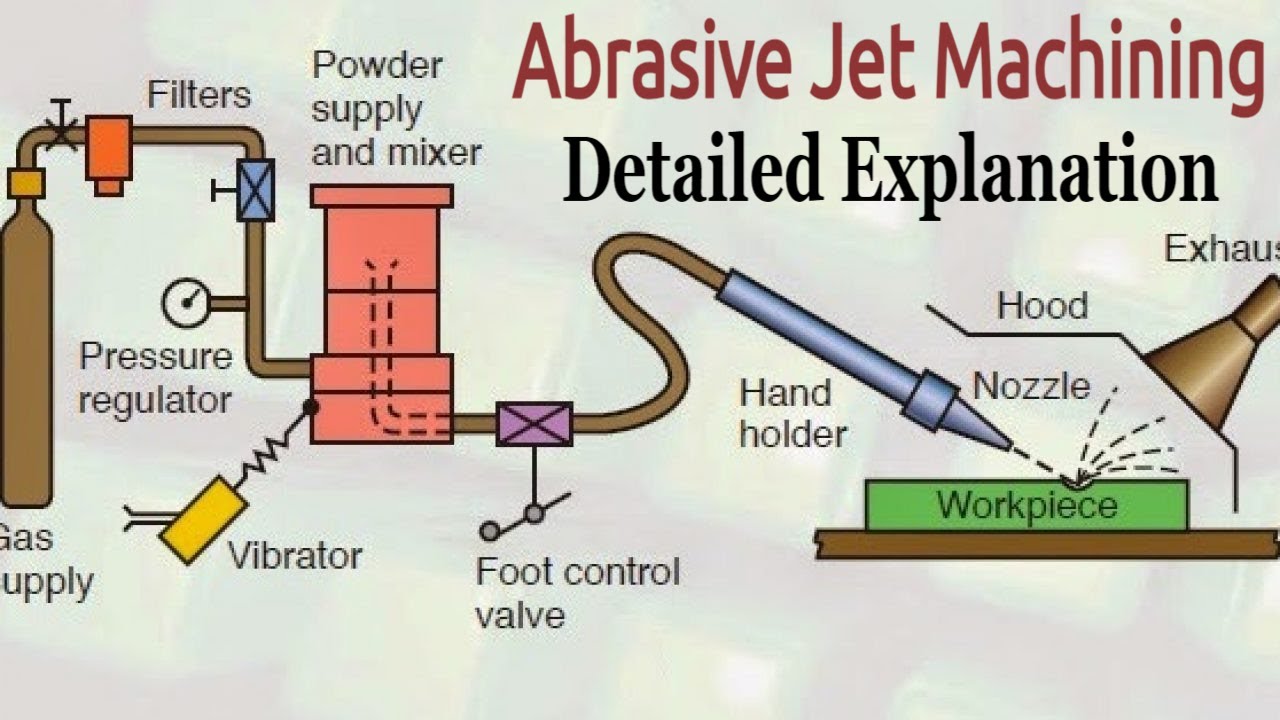

How an Abrasive Jet Machining Works?

Materiais e Processos de Fabricação para Engenharia de Produção - Usinagem convencional: conceitos

Types of Drill jigs & Requirement of Drill jig ||Engineer's Academy||

All Lathe Machine Operations: Turning, Facing, Taper Turning, Boring, Knurling, Tapping, Forming

WATER JET MACHINE PROCESS : Working of abrasive water Jet machining process (animation).

5.0 / 5 (0 votes)