Bombas Centrífugas - Tipos

Summary

TLDRThis video provides an in-depth look at various types of centrifugal pumps, focusing on their construction and design. It covers different configurations, such as monoblock pumps, single and double suction rotors, horizontal and vertical shaft designs, and multi-stage pumps. The presenter explains key concepts such as the function of bearings, motor and pump shaft separation, and the importance of alignment for maintenance. Additionally, it touches on specialized pumps like submersible, axial, and magnetic seal pumps, emphasizing their unique applications and advantages. The content is aimed at professionals and students looking to deepen their understanding of pump mechanics and their practical uses.

Takeaways

- 😀 The video discusses various types of centrifugal pumps, including their construction and operation.

- 😀 It is recommended to watch the video on fluid trajectory through the rotor to better understand the content.

- 😀 Pumps are classified based on their construction, such as mancalized (bearing-supported) pumps with horizontal shafts.

- 😀 Manacalized pumps have bearings at both ends of the rotor and are often referred to as single-stage pumps because they contain one rotor.

- 😀 Monoblock pumps feature a single shaft, simplifying alignment, and are preferred by maintenance professionals due to their reduced need for alignment.

- 😀 A distinction is made between simple and double suction rotors, with double suction allowing fluid entry from both sides of the rotor.

- 😀 Multi-stage pumps are used to increase pressure (not flow rate), with each rotor boosting pressure gradually.

- 😀 Radial and axial split pumps differ in how they are opened for maintenance, with radial splits involving perpendicular openings to the axis.

- 😀 Vertical inline pumps save installation space by aligning suction and discharge in the same line, often using mechanical seals for leakage prevention.

- 😀 Submersible pumps, often used for deep well applications, operate fully immersed in fluid, with a motor and impeller at different ends of the pump body.

Q & A

What is the primary focus of the video?

-The video primarily discusses the construction and types of centrifugal pumps, including various designs, features, and how they function.

What is meant by a 'single-stage' centrifugal pump?

-A single-stage centrifugal pump refers to a pump with only one rotor, where the fluid enters through a single side and is expelled from the same side after passing through the rotor.

Why is a centrifugal pump with a 'horizontal shaft' referred to as 'horizontal'?

-A centrifugal pump with a horizontal shaft is called 'horizontal' because the shaft of the pump is oriented in a horizontal position relative to the ground.

What does 'balancing rotor' mean in centrifugal pumps?

-A 'balancing rotor' refers to a rotor positioned at the end of the pump shaft, which can cause the rotor to swing or wobble slightly during operation, though it is not always visually apparent.

What is the significance of a 'double suction rotor' in a centrifugal pump?

-A double suction rotor allows fluid to enter the pump from both sides of the rotor, helping to balance the hydraulic forces and improve pump performance, especially in high flow applications.

What is the difference between a 'monobloc' centrifugal pump and a conventional pump?

-A monobloc centrifugal pump has a single shaft that connects both the motor and the pump rotor, eliminating the need for alignment. In contrast, conventional pumps have separate shafts for the motor and rotor that require precise alignment.

What does 'multi-stage' mean in centrifugal pumps?

-A multi-stage centrifugal pump contains multiple rotors (or stages) that increase the pressure of the fluid incrementally with each stage. However, these pumps do not increase the flow rate; they only increase the pressure.

What is the role of 'flange connections' in centrifugal pumps?

-Flange connections in centrifugal pumps allow for easy attachment and detachment of pipes to the pump for both suction and discharge, ensuring a secure connection and ease of maintenance.

How do 'radial' and 'axial' openings differ in centrifugal pumps?

-In radial-opening pumps, the opening for fluid entry and exit is perpendicular to the pump shaft, while in axial pumps, the fluid enters and exits along the axis of the shaft.

What is the main advantage of a 'vertical inline' centrifugal pump?

-The main advantage of a vertical inline centrifugal pump is its compact design, requiring less installation space compared to horizontal pumps. It is typically used in situations where space is limited.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

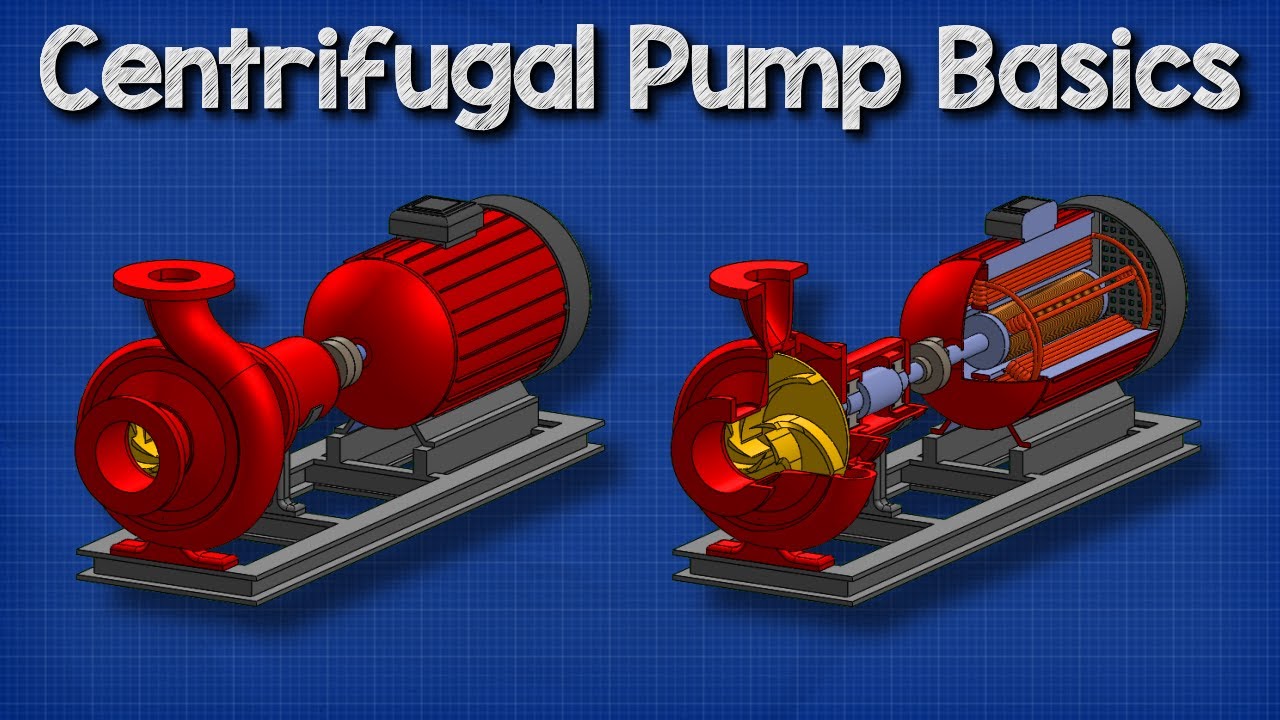

Centrifugal Pump Basics - How centrifugal pumps work working principle hvacr

Yuk Belajar Tentang Pompa-Pompa di atas Kapal (Part 1) - Lilin Tua #pompa #kapal #belajar #pelaut

Hydraulic Training Series - Chapter 2 - Hydraulic Pumps

PART-1: Technical Evaluation of Centrifugal Pump Mechanical Datasheet with respect to API 610

I POMPA AIR PART 1

Centrifugal Pump Basics I Definition I Working I Velocity Triangle I Work Done I Head I Efficiency

5.0 / 5 (0 votes)