DISTRIBUTE CONTROL SYSTEM (DCS) SISTEM KONTROL TERDISTRIBUSI - DALAM OTOMASI INDUSTRI

Summary

TLDRThis video script provides an in-depth exploration of Distributed Control Systems (DCS) used in industrial automation. It covers the fundamentals of DCS, its components, and architecture, comparing it with other control systems like SCADA and PLC. The script delves into the various functions of DCS in industries, including process control, data collection, and enhancing operational safety. It also emphasizes DCS programming, alarm management, and troubleshooting. Case studies highlight DCS's role in power plants and chemical plants, demonstrating its importance in improving efficiency, safety, and system reliability in complex, continuous industrial processes.

Takeaways

- 😀 DCS (Distributed Control System) is an automated control system used for managing industrial processes with a distributed architecture.

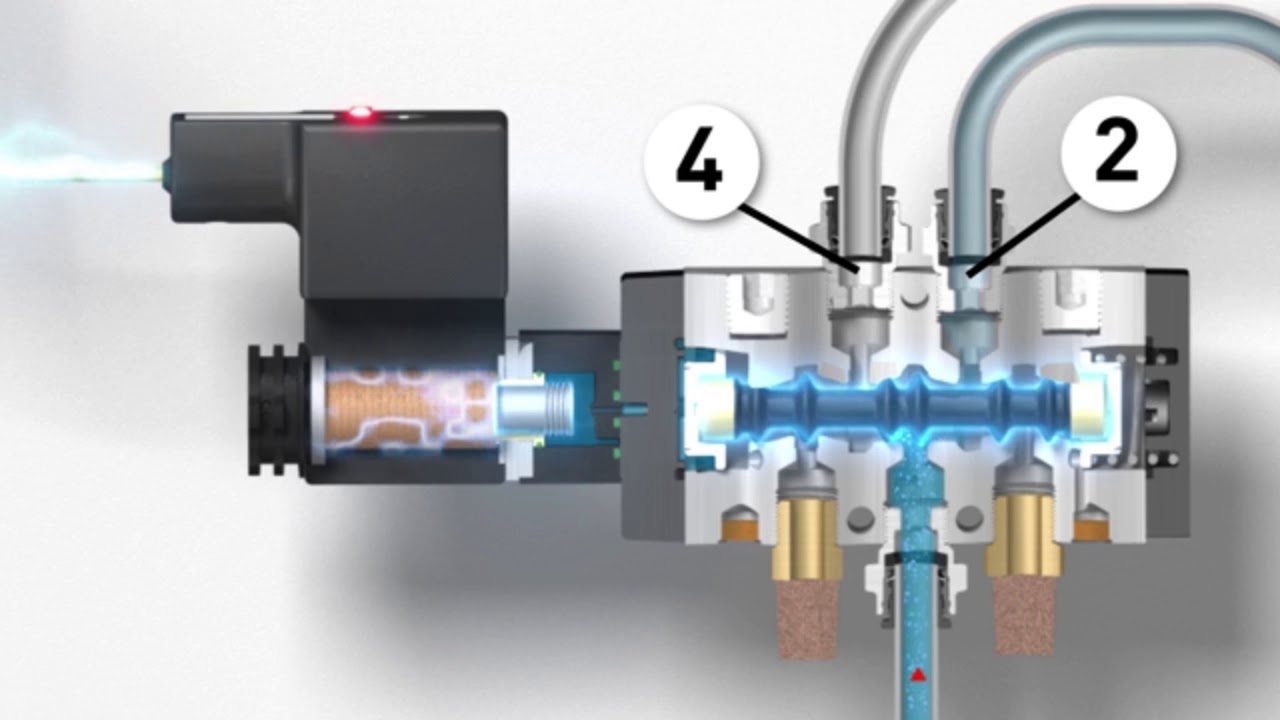

- 😀 The main components of a DCS include control units, sensors, actuators, and Human-Machine Interface (HMI) for monitoring and control.

- 😀 DCS is ideal for continuous processes, such as temperature, pressure, flow, and level control in industries like power plants and chemical manufacturing.

- 😀 DCS differs from SCADA and PLC in terms of focus: DCS handles continuous process control, SCADA is used for monitoring over large geographical areas, and PLC is for discrete control tasks.

- 😀 DCS architecture allows for distributed control, with units managing local data processing, reducing the load on central systems and improving system response times.

- 😀 Communication in DCS is achieved through industry-standard protocols like Modbus and Profibus, ensuring reliable and fast data transfer between components.

- 😀 Redundancy is a key feature in DCS, enhancing system reliability by providing backup components in case of failure, ensuring continuous operation in critical industries.

- 😀 DCS improves operational safety by providing alarms and system monitoring, reducing the risk of human error and ensuring stable and secure operation.

- 😀 Programming in DCS involves creating control logic through graphical blocks (e.g., PID, Boolean logic) without needing complex coding, making it easier to implement control strategies.

- 😀 Troubleshooting in DCS involves identifying and analyzing issues at the hardware, software, and network levels, utilizing diagnostic tools to ensure smooth operation of the system.

- 😀 Case studies show that DCS implementation in power plants and chemical industries leads to efficient process control, enhanced safety, and operational consistency.

Q & A

What is a Distributed Control System (DCS)?

-A Distributed Control System (DCS) is an automated control system designed to manage industrial processes with a distributed architecture. It involves multiple control units spread across different locations within a facility, all integrated through a communication network for coordinated control.

How does DCS differ from SCADA and PLC systems?

-DCS is designed for continuous processes such as temperature, pressure, or flow, used in large, complex industries like chemical plants or power stations. SCADA focuses on supervisory control and data acquisition over large geographical areas and is more about monitoring than control. PLC systems are used for discrete logic control tasks in localized, smaller-scale operations like controlling machines or assembly lines.

What are the main components of a DCS?

-The main components of a DCS include controller units (which process control logic), Human-Machine Interface (HMI) for visual monitoring and control, field devices such as sensors and actuators to measure and control process parameters, and a communication network that connects all these components using industry protocols.

What is the role of the Human-Machine Interface (HMI) in a DCS?

-The HMI is a visual interface that allows operators to monitor system conditions, control processes, and receive notifications or alarms about system issues, thus providing real-time insights and control over the industrial process.

Why is a distributed architecture important in a DCS?

-A distributed architecture in DCS allows control to be decentralized, where each unit handles local data processing independently. This reduces the load on a central control unit, speeds up response times, and enhances the system's reliability by providing fault tolerance through redundancy.

What are the benefits of redundancy in a DCS?

-Redundancy in a DCS ensures system reliability by having backup components such as controllers, networks, and HMIs that can take over in case of failure. This prevents system downtime, which is crucial in industries like power generation, where continuous operation is essential.

How does DCS improve safety in industrial operations?

-DCS improves safety by offering features like alarm systems, data redundancy, and emergency control capabilities. These features help reduce human errors, provide early warnings, and ensure the system remains stable and safe, even in critical conditions.

What are the key aspects of programming in a DCS?

-Programming in a DCS involves creating control logic for industrial processes using function blocks like PID (Proportional-Integral-Derivative), Boolean logic, and flow diagrams. The programming is often graphical and based on international standards like IEC 61131-3, with languages like Ladder Diagram or Structured Text.

What role does data collection and processing play in a DCS?

-Data collection and processing in DCS are vital for monitoring the status of various sensors, analyzing process parameters, and displaying this data on the HMI. It helps operators make informed decisions and ensures that processes are controlled and optimized efficiently.

What is the process of troubleshooting in a DCS?

-Troubleshooting in a DCS involves diagnosing and resolving issues in the system. It starts with identifying symptoms like persistent alarms or slow responses, followed by systematically checking hardware (such as I/O modules and communication networks) and software (like control logic and configuration) to find and fix the root cause.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

5.0 / 5 (0 votes)