Pasang bospom dan cara cari top bospom dan FO

Summary

TLDRThis video tutorial provides a detailed step-by-step guide on how to properly adjust and align the engine timing for various models, including 8DC11, 8DC9, and 8DC10. The presenter explains the process of setting the top position of the engine, adjusting the timing marks, and ensuring the alignment of components such as the compressor and the bos pump. Emphasis is placed on precision, with tips on checking for alignment using markings and fine-tuning the engine's performance. The video also touches on practical tips and safety measures for securing parts and tightening bolts.

Takeaways

- 😀 The speaker explains the process of aligning engine components, focusing on top-dead-center (TDC) adjustments for accurate engine timing.

- 😀 The timing tool and adjustments ensure the compressor aligns correctly with the engine gears to prevent misalignment during operation.

- 😀 The speaker emphasizes the importance of securing the engine parts at TDC, with measurements marked at specific intervals (14, 13, 12, etc.) to maintain proper alignment.

- 😀 The TDC process involves adjusting the engine's timing marks and ensuring the components are precisely aligned before tightening any bolts.

- 😀 The speaker demonstrates how to adjust and secure the timing by using specific tools, such as a 17mm wrench, to maintain the engine's integrity.

- 😀 The process includes checking the alignment at different intervals and making sure the marks on the engine match to ensure proper timing.

- 😀 The speaker demonstrates the importance of checking the alignment of the engine components after making adjustments to ensure they remain in sync.

- 😀 Once the engine's timing is correctly set, the speaker proceeds to tighten the components securely, ensuring they do not move out of alignment.

- 😀 The speaker highlights the need to check and recheck the alignment when installing the components back into place, ensuring everything is tightened and positioned properly.

- 😀 The speaker concludes by reinforcing the need for precision when adjusting the engine's timing and ensuring proper torque for long-term reliability.

Q & A

What is the main topic of the video script?

-The main topic of the video script is the process of toping and adjusting the timing of a machine, specifically related to setting the timing of a DC 8 engine.

What is the significance of aligning the machine parts during the process?

-Aligning the machine parts, such as the gears and timers, ensures that the engine operates smoothly and that the toping is accurate. This alignment helps to prevent misfiring or improper synchronization.

What does the term 'top sat' refer to in the context of the video?

-'Top sat' refers to the correct top position or setting of the engine, ensuring that the machine parts are aligned correctly for optimal operation.

Why is it important to adjust the timing of the compressor and gears?

-Adjusting the timing of the compressor and gears ensures that the engine runs efficiently. It helps synchronize the components so that the engine performs at its best, preventing any potential damage or misfire.

What does the video demonstrate regarding the 'lurus' (alignment) of the parts?

-The video emphasizes the importance of making sure the parts are properly aligned or 'lurus.' This alignment ensures the timing marks match correctly, which is essential for proper machine operation.

How is the 'bospom' mentioned in the video related to the process?

-'Bospom' seems to refer to a component or part of the machine that needs to be aligned or adjusted as part of the timing process. The video highlights the need to check and align this part carefully during the process.

What tool is primarily used to tighten the components?

-The tool primarily used to tighten the components is a 17-sized wrench or spanner, as mentioned multiple times in the video.

Why is it necessary to adjust the timing when the engine is at 'Top S'?

-Adjusting the timing at 'Top S' ensures that the engine components are set at their optimal position for proper operation. This step is crucial for preventing errors and maintaining engine efficiency.

What is the role of the lines and markings mentioned in the video?

-The lines and markings are used as reference points to ensure the correct alignment of the components. These markings help verify that the timing is set accurately and the components are aligned correctly.

What happens if the engine components are not properly aligned?

-If the engine components are not properly aligned, it can lead to issues such as misfiring, inefficient engine performance, or even damage to the machine due to improper timing or synchronization.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

CARA POINTING ANTENA BTS MICROWAVE 0.3 0.6 METER HUAWEI

CARA MENCARI SINYAL KVISION PARABOLA KECIL DI SATELIT TERBARU MEASAT 3B

How To Replace Timing Chain Tensioner 2010-2017 Chevy Equinox

Tutorial cara memakai beskap, pakaian adat Jawa

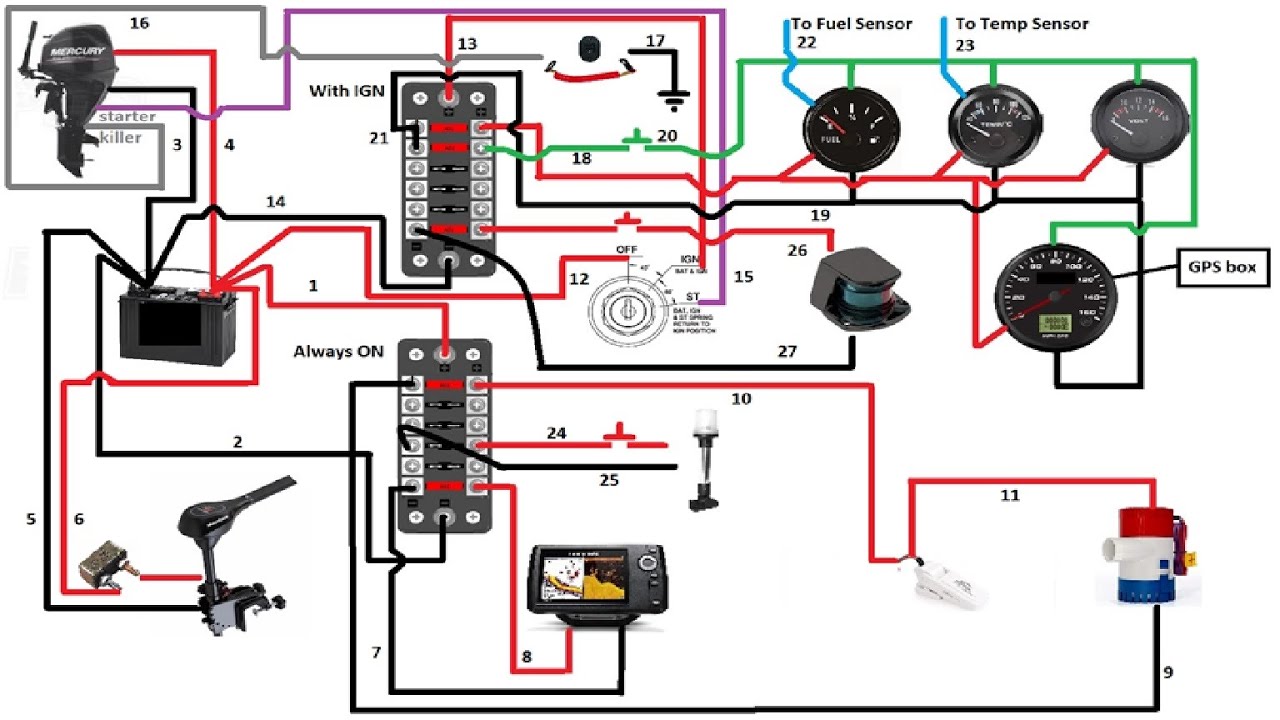

Boat electronic wiring diagram

Using a microscope The parts and how to focus

5.0 / 5 (0 votes)