How To Replace Timing Chain Tensioner 2010-2017 Chevy Equinox

Summary

TLDRThis video provides a detailed step-by-step guide on performing maintenance and repairs on a vehicle’s engine components. The process includes removing and reinstalling parts such as the PCM, airbox, coil packs, serpentine belt, harmonic balancer, and timing components. The instructions cover proper handling of tools, torque specifications, and key steps like adjusting the timing chain, replacing the gasket, and cleaning surfaces. The video is designed for car enthusiasts or DIYers looking to perform a thorough engine service, providing clear instructions and tips to complete the job effectively.

Takeaways

- 😀 Remove the 10mm bolt holding the PCM in place, and slide the computer out of the vehicle.

- 😀 Disconnect the negative terminal using a 10mm socket to avoid electrical issues.

- 😀 Use a straight blade screwdriver to loosen the worm clamps on the snorkel and remove it.

- 😀 Disconnect connectors and remove the airbox by unscrewing the 10mm bolts and dislodging the connectors.

- 😀 Remove the coil packs by sliding back the locks, unbolting them, and pulling them out carefully.

- 😀 Take out the necessary hoses, connectors, and solenoids to clear the area for further disassembly.

- 😀 Unscrew and remove the valve cover, taking care not to damage any components underneath.

- 😀 Remove the timing chain cover by loosening several bolts and prying it off, allowing access to the internal components.

- 😀 Use a crank bolt to rotate the crankshaft and align the timing marks correctly.

- 😀 Replace the timing chain tensioner and torque it to 55 foot-pounds for secure installation.

- 😀 Ensure the proper timing alignment by rotating the engine clockwise and verifying the position of camshaft and crankshaft marks.

- 😀 Carefully replace the valve cover gasket and air intake components, making sure all connections are secure before reassembling.

Q & A

What is the first step in removing the PCM (Powertrain Control Module) from the vehicle?

-The first step is to use a 10mm socket to remove a 10mm bolt that holds the PCM down. Once the bolt is removed, the computer can be slid towards the outside of the vehicle and then upward.

Why is it important to disconnect the negative terminal of the battery?

-Disconnecting the negative terminal of the battery prevents any electrical shorts or accidental activation of electrical components while working on the vehicle.

What tool is used to loosen the worm clamp above the throttle body?

-A straight blade screwdriver is used to loosen the worm clamp above the throttle body.

What should be done to prevent debris from falling into the intake manifold during disassembly?

-The cover should be put back on the intake manifold to ensure nothing falls into it while other components are being removed.

What steps should be taken to remove the valve cover?

-To remove the valve cover, first remove all the bolts around its perimeter using a 10mm socket. Be sure to also remove the hidden bolt at the bottom. Afterward, carefully slide the valve cover up, prying if necessary, without damaging the gasket.

What is the role of the timing tool when working on the engine's timing components?

-The timing tool ensures that the timing is correct by aligning the timing marks on the camshaft and crankshaft sprockets. It helps keep the timing components in sync when replacing or adjusting the timing chain.

How do you release tension from the timing chain tensioner?

-To release the tension from the timing chain tensioner, use a screwdriver with a rubber foot to push against the chain guide and release the locking mechanism, essentially 'pulling the pin' on the tensioner.

What is the purpose of trimming the gasket around the engine bracket?

-The gasket needs to be trimmed around the engine bracket so it can fit properly when the timing cover is reinstalled. This avoids having to remove the engine bracket, saving time during reassembly.

How is the crank pulley reinstalled and torqued correctly?

-The crank pulley is reinstalled by first aligning it and securing it with the new crank bolt. The crank bolt is then torqued to 100 foot-pounds, followed by an additional 100 degrees of rotation.

What should be checked when installing the new valve cover gasket?

-When installing the new valve cover gasket, ensure it is seated properly all the way around the cover and that it does not fall out of position during the reinstallation. Additionally, check that all pins line up and that the gasket doesn’t pinch any wires.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

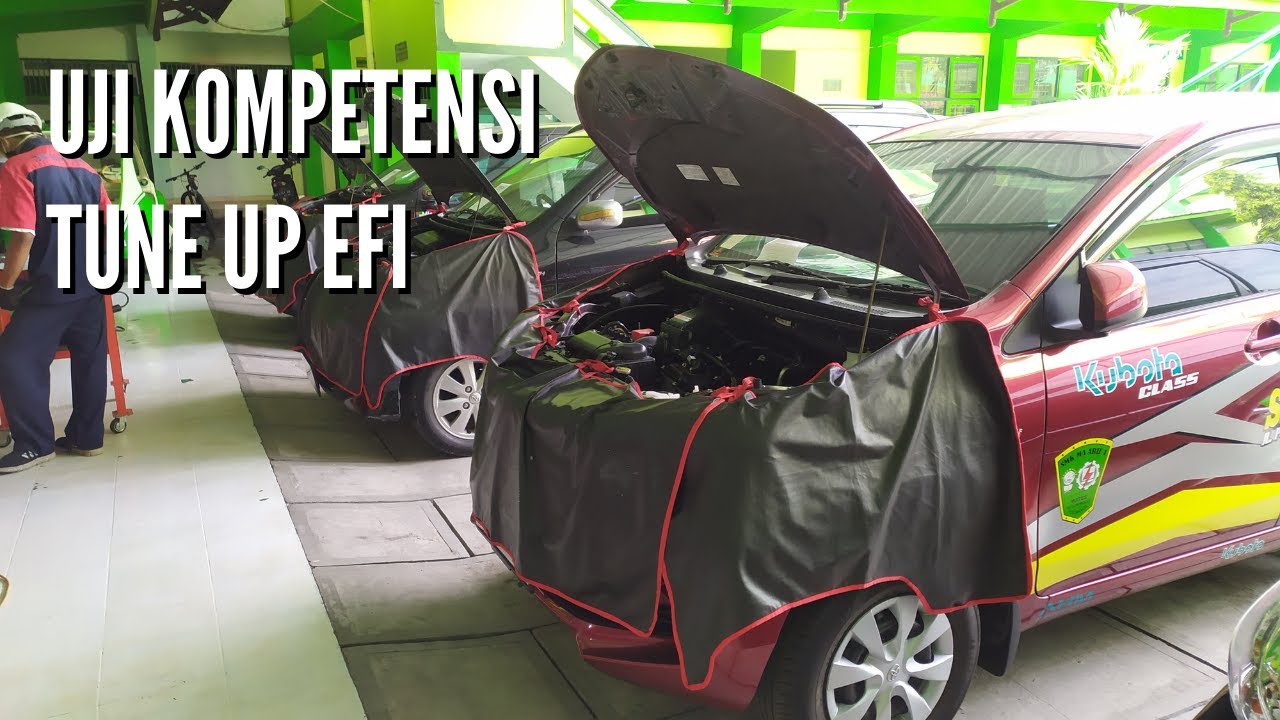

TUNE UP EFI - UKK TUNE UP EFI - UJI KOMPETENSI EFI - UJIAN PRAKTIK TKR

Vidio Tutorial Merawat Sensor PGM-Fi

PEMELIHARAAN STEAM TURBINE JOURNAL BEARING - NAZAR ADAM A. - PT.PJB UPHT

Tutorial Praktis Perawatan Mesin Traktor agar Selalu Fit

Cara Membersihkan Karbu Honda Beat 2010

Materi PMKR Tune Up Mesin Bensin Konvensional 🛠🛠

5.0 / 5 (0 votes)