Hydraulic Training Series - Chapter 2 - Hydraulic Pumps

Summary

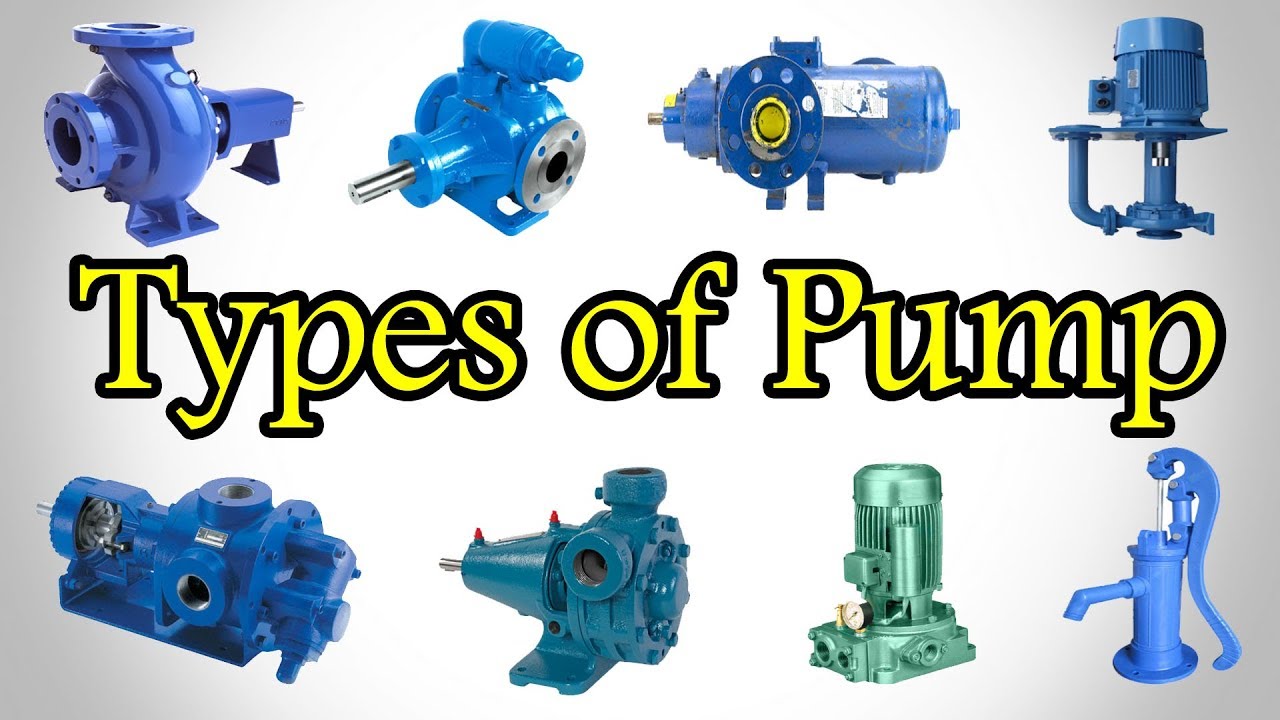

TLDRThis video presentation covers the fundamentals of hydraulic pumps, focusing on the two main types: positive displacement and non-positive displacement. It explains how non-positive pumps use centrifugal force, making them inefficient for hydraulic systems, while positive displacement pumps deliver a fixed quantity of fluid per cycle, ideal for high-pressure applications. The video explores various positive displacement pump types, including gear, vane, and piston pumps, discussing their design, performance, and specific applications. It emphasizes the importance of pumps in hydraulic systems, drawing a parallel to the human heart in its crucial role in machinery operation.

Takeaways

- 😀 Hydraulic pumps are essential components in hydraulic systems, with two main categories: positive displacement and non-positive displacement pumps.

- 😀 Non-positive displacement pumps, like centrifugal pumps, use centrifugal force to move fluids but are impractical for modern hydraulic systems due to their inability to maintain consistent pressure.

- 😀 Positive displacement pumps deliver a fixed amount of fluid per cycle, with pressure determined by the pump's workload, and are commonly used in hydraulic systems.

- 😀 Gear pumps are one of the simplest positive displacement pump types, using meshing gears to displace fluid and can operate at pressures up to 3000 psi.

- 😀 Vane pumps are favored for their high efficiency, low noise, and long lifespan. They use vanes that follow the contour of a rotor and are typically limited to pressures around 2500 psi.

- 😀 A balanced vane pump configuration reduces unbalanced hydraulic loading and offers the ability to adjust displacement by changing the cam ring position.

- 😀 Sperry Vickers offers various models of vane pumps, such as the V104 (quiet but limited to 1000 psi) and V20 (used in mobile vehicles, with pressures up to 2500 psi).

- 😀 The Intravane series is a high-performance vane pump capable of pressures up to 3000 psi and flow rates of 109 GPM, using advanced features like intravein inserts to improve vein tracking at high speeds.

- 😀 Piston pumps, including radial and axial piston designs, are used for high-efficiency and high-pressure applications, commonly found in aircraft, military equipment, and large hydraulic presses.

- 😀 Axial piston pumps can be variable displacement, allowing for changes in flow direction and output through adjustments in the swashplate angle, making them highly versatile in hydraulic systems.

- 😀 The pump is often referred to as the 'heart' of the hydraulic system, with an inefficient pump leading to system failure, much like how the heart's malfunction can affect the circulatory system.

Q & A

What are the two basic categories of pumps mentioned in the presentation?

-The two basic categories of pumps mentioned are positive displacement pumps and non-positive displacement pumps.

How do non-positive displacement pumps operate?

-Non-positive displacement pumps primarily operate using centrifugal force. Fluids are thrown to the outside of the pump housing by a rapidly driven impeller, with no positive seal between the inlet and outlet ports, which makes the pressure dependent on the drive speed.

Why are non-positive displacement pumps impractical for most modern hydraulic systems?

-Non-positive displacement pumps are impractical for most modern hydraulic systems because the pressure they generate is a function of the drive speed and decreases as resistance increases, making them inefficient for high-pressure applications.

What is the key feature of positive displacement pumps?

-Positive displacement pumps deliver a definite quantity of fluid for every stroke, revolution, or cycle. The pressure generated is determined by the workload, and the fluid displaced during the intake stroke is forced through the pump outlet.

How does a gear pump work?

-A gear pump consists of two meshing gears within a close-fitting housing. As the gears rotate, a partial vacuum is created at the inlet, drawing fluid in. The fluid is then carried around the gears and forced out through the outlet port, generating high pressure at the outlet.

What is unbalanced hydraulic loading in gear pumps, and how is it mitigated?

-Unbalanced hydraulic loading in gear pumps occurs when one side of the gear experiences higher pressure than the other, leading to wear. This issue is mitigated by using flexible wear plates that reduce clearance and allow oil to extend further around the gears.

What are the key advantages of vane pumps in hydraulic systems?

-Vane pumps are favored for their high efficiency, low noise levels, and long life. They work with centrifugal force and pressure to hold vanes against the cam ring, providing a stable fluid delivery.

What differentiates a balanced vane pump from an unbalanced vane pump?

-A balanced vane pump has an elliptical cam ring, which creates two sets of interconnected pumping chambers. This design cancels out the forces caused by pressure buildup, reducing unbalanced hydraulic loading and improving efficiency.

Why are piston pumps used in aircraft and military applications?

-Piston pumps are used in aircraft and military applications due to their high efficiency, ability to handle high pressure, and reliability under demanding conditions, despite their higher cost.

What is the difference between a radial piston pump and an axial piston pump?

-In a radial piston pump, pistons reciprocate radially within a rotating cylinder block, while in an axial piston pump, pistons are parallel to each other and to the cylinder block axis, with either a bent-axis or inline design.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Yuk Belajar Tentang Pompa-Pompa di atas Kapal (Part 2) - Lilin Tua #pompa #kapal #belajar #pelaut

Types of Pumps | All in One Guide to Industrial Pump Types

Tertarik tentang Mechanical ?? Yuk pelajari Dasar-Dasar Mechanical

Types of pump | Working methods

Pumps Types - Types of Pump - Classification of Pumps - Different Types of Pump

Pengetahuan Dasar Instalasi Mesin Kemudi Kapal Jenis Elektro Hydraulik - Part 1 #belajaronline

5.0 / 5 (0 votes)