Steel Manufacturing - Including Blast Furnace and BOS

Summary

TLDRThe production of steel, a fundamental material for countless applications, involves several key processes starting from iron ore, coke, and limestone in a blast furnace. This method produces molten iron, which is refined into steel using techniques like Basic Oxygen Steelmaking and Electric Arc Furnace methods. Secondary processes further enhance steel quality, while continuous casting solidifies it into various shapes. The rolling process shapes the steel into finished products, with cold rolling improving surface quality. With a focus on recycling, steel remains a vital and sustainable material in modern industry, continuously evolving to meet new demands.

Takeaways

- 😀 Steel is a fundamental material used in a wide range of products, from cars and buildings to everyday items like cutlery and cans.

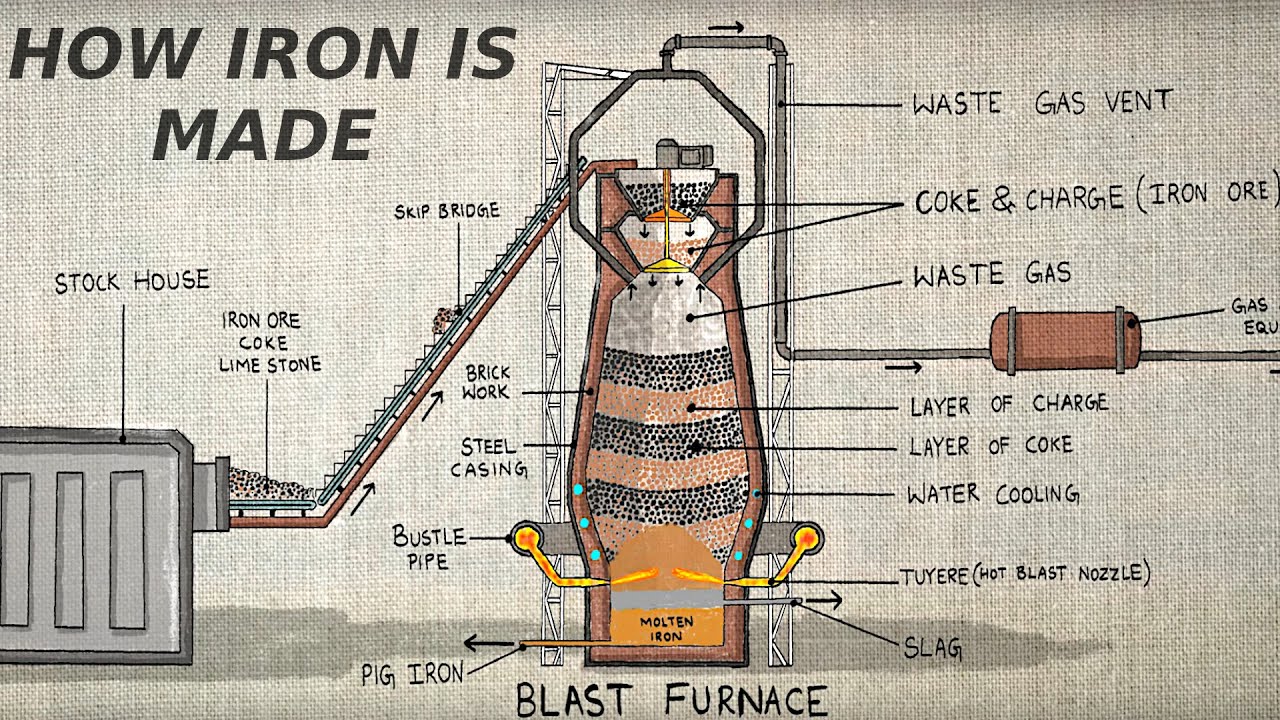

- 🔥 The production of steel begins with iron ore, coke, and limestone in a blast furnace, where these materials are heated to extremely high temperatures.

- ⚙️ Molten iron, produced from the blast furnace, is not pure and contains impurities like carbon, sulfur, and silicon that need to be refined to make steel.

- 🌍 Basic Oxygen Steelmaking (BOS) is a primary method for converting molten iron into steel, using high-purity oxygen to oxidize impurities.

- ⚡ Electric Arc Furnaces (EAF) predominantly use recycled steel scrap, making this method a major component of global steel recycling efforts.

- 🛠️ After the primary steelmaking process, secondary processes ensure the steel meets precise specifications for temperature and composition.

- 📏 Continuous casting is employed to solidify molten steel, creating various shapes like billets, slabs, and blooms ready for further processing.

- 🌀 Hot rolling is used to shape steel while it's hot, achieving the desired thickness and shape with immense force from heavy rolls.

- 🌱 Cold rolling produces thinner, flatter products with improved surface finish and is often used for products requiring corrosion protection.

- ♻️ Nearly half of the world’s steel production comes from recycled materials, emphasizing steel's status as the most recycled material globally.

Q & A

What are the primary raw materials used in steel production?

-The primary raw materials are iron ore, coke, and limestone.

What is the role of coke in the blast furnace?

-Coke provides the necessary carbon for the blast furnace and serves as a fuel to reach the high temperatures required for melting iron.

How is molten iron produced in a blast furnace?

-Iron ore, coke, and limestone are fed into the blast furnace, where a hot air blast raises the temperature to around 2,200 degrees Celsius, melting the materials to form molten iron.

What is the purpose of sintering in the steelmaking process?

-Sintering reduces waste and provides an efficient raw material for the blast furnace by blending different iron ores.

How does basic oxygen steelmaking (BOS) convert molten iron into steel?

-In BOS, scrap steel is added to the molten iron, and high-purity oxygen is blown onto it, oxidizing impurities and producing heat, which helps refine the steel.

What distinguishes an electric arc furnace (EAF) from other steelmaking methods?

-EAF primarily uses recycled steel scrap and can melt large quantities in less than an hour, allowing for precise control over steel composition.

What is continuous casting and why is it important?

-Continuous casting solidifies molten steel into shapes like billets and slabs, which are ready for further processing into finished products.

What are some common finished products made from steel?

-Common finished products include beams, rods, wire, tubes, plates, and strips used in various industries.

Why is cold rolling used in steel processing?

-Cold rolling produces thinner, flatter products with better surface finishes than hot rolling and is used for applications requiring high precision.

How does the steel industry contribute to recycling?

-The steel industry is the world's most recycled material, with around 400 million tons of steel produced annually from recycled sources.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführen5.0 / 5 (0 votes)