PLC Tutorial 8 : PID Control in Programmable Logic Controller (PLC)

Summary

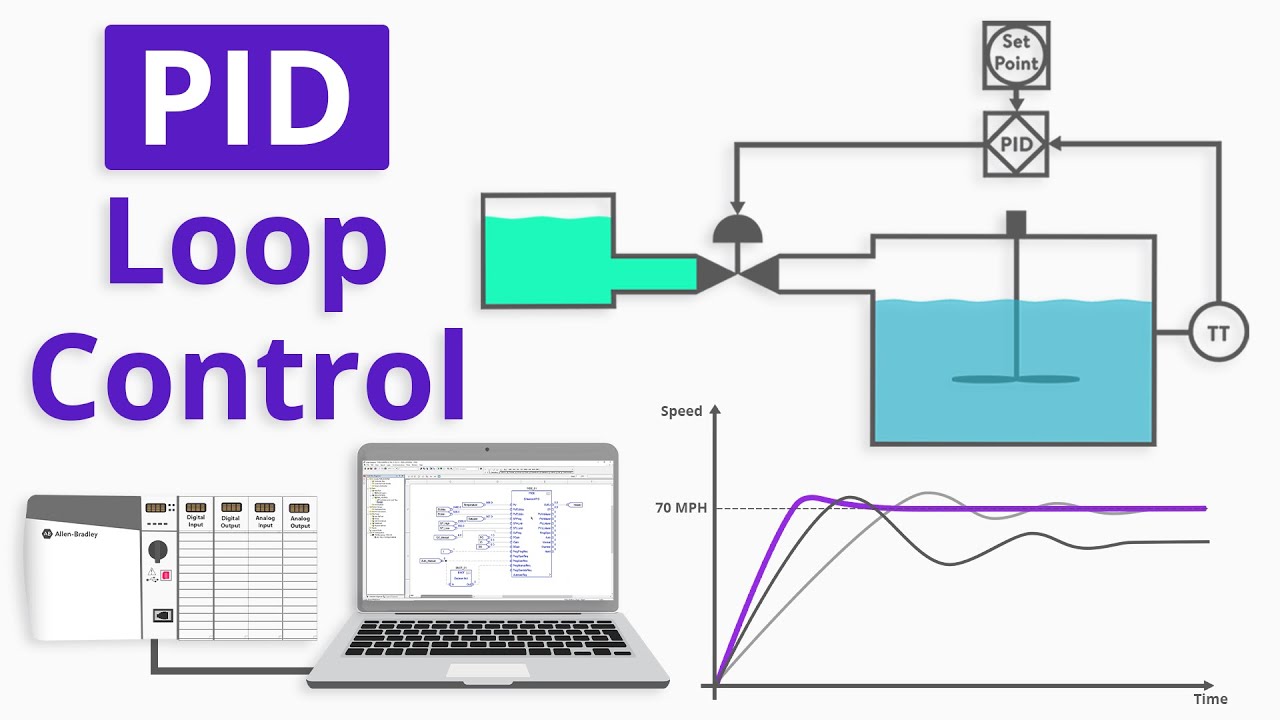

TLDRThis video introduces the concept of PID (Proportional, Integral, Derivative) control in automation, explaining its critical role in closed-loop control systems. It contrasts open-loop systems, which lack feedback and stability, with closed-loop systems that utilize feedback for accurate control. The presenter demonstrates configuring a PID controller using a Siemens 1200 series PLC, detailing the setup of parameters like setpoints and tuning gains. Through real-time monitoring and graphing of inputs and outputs, viewers learn how PID controllers continually adjust to minimize error, ensuring effective temperature regulation and system stability.

Takeaways

- 😀 PID stands for Proportional, Integral, and Derivative control, which is vital for stabilizing processes in automation.

- 📊 Open-loop control systems operate without feedback, leading to potential inaccuracies and instability.

- 🔄 Closed-loop control systems utilize feedback mechanisms to adjust outputs and maintain desired setpoints.

- ⚙️ The PID controller continuously calculates error values and rectifies them to match the desired output.

- 🏭 The tutorial focuses on configuring PID control in a Siemens 1200 series PLC using specific programming blocks.

- 🛠️ Tuning parameters like KP (proportional gain), KI (integral time), and KD (derivative time) are crucial for optimal PID performance.

- 🔍 Monitoring real-time data helps in adjusting the PID settings to achieve desired output stability.

- 📉 The PID response can be configured for faster performance by using cyclic interrupt options in the PLC.

- 📈 A graphical interface demonstrates how input changes affect output responses, showcasing PID functionality.

- ❓ Viewers are encouraged to engage with questions and comments for further clarification and support.

Q & A

What is the purpose of PID control in a closed-loop system?

-PID control is used to maintain a desired output by continuously calculating the error between the setpoint and the process variable, adjusting the control output accordingly to ensure stability and accuracy.

How does an open-loop control system differ from a closed-loop control system?

-An open-loop control system does not provide feedback, which can lead to instability and an inability to reach the desired output. In contrast, a closed-loop system utilizes feedback from sensors to adjust the process and maintain the desired setpoint.

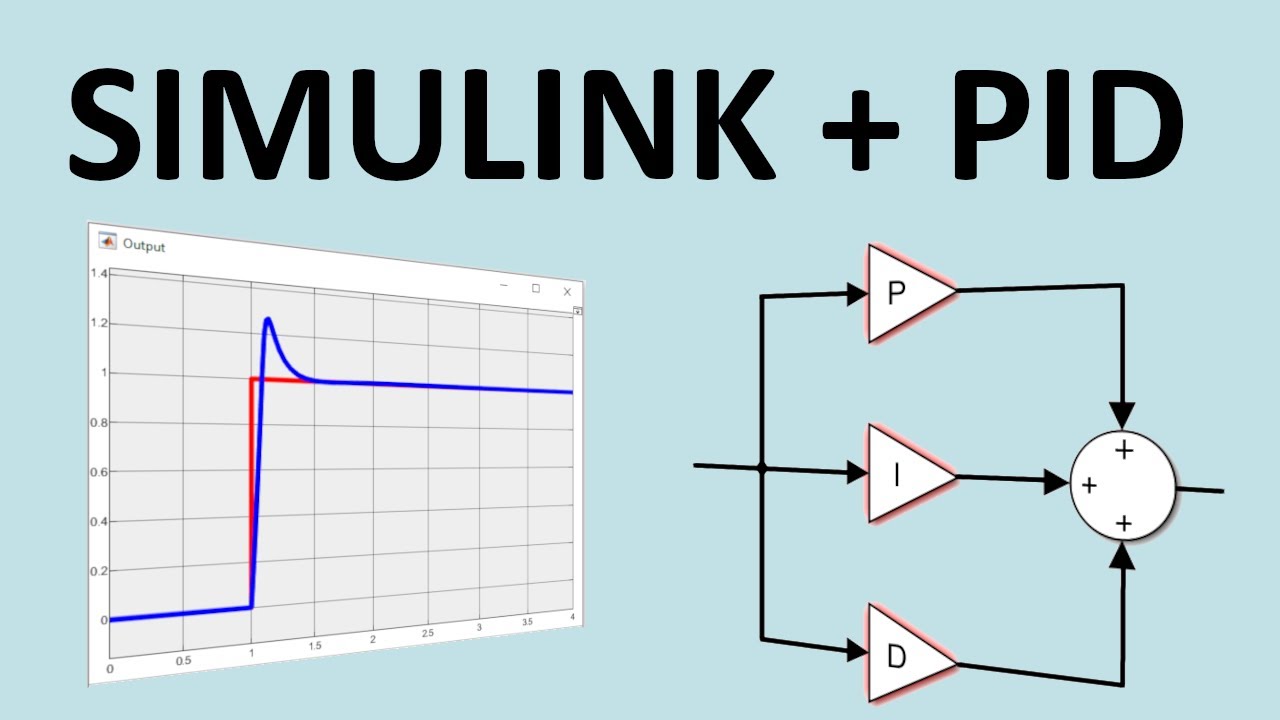

What are the three components of PID control?

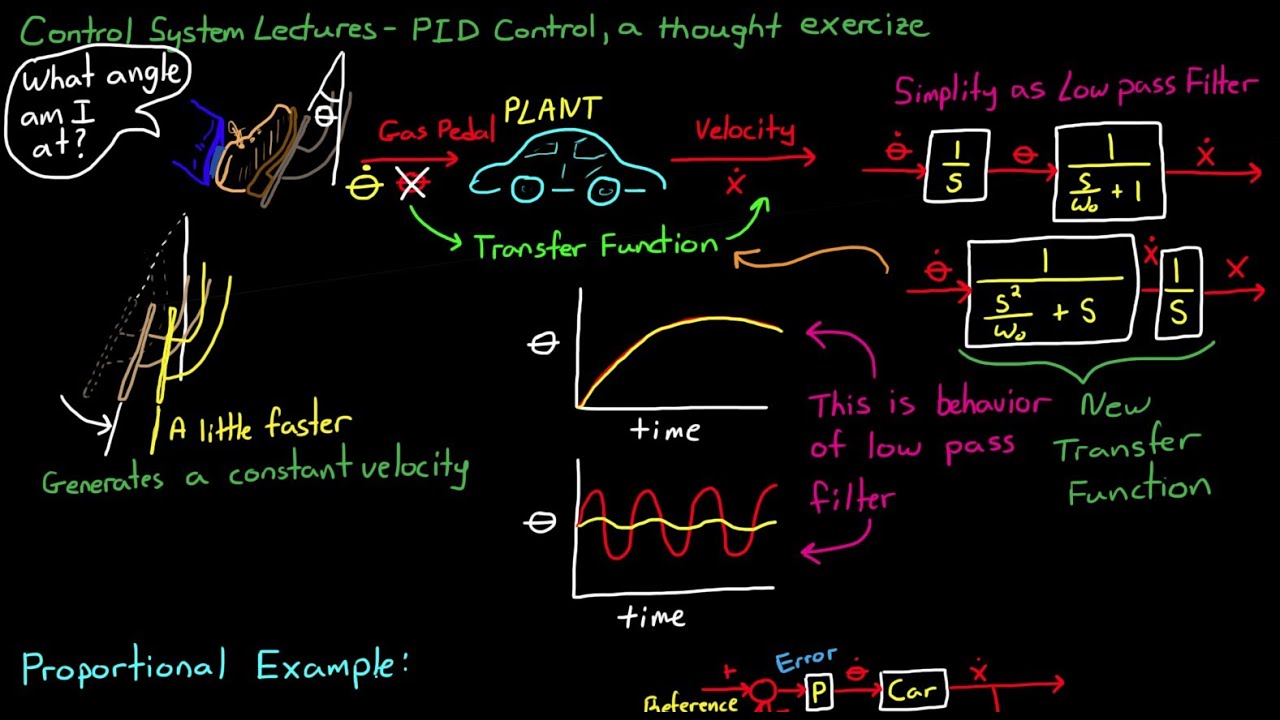

-The three components of PID control are Proportional (P), Integral (I), and Derivative (D). Proportional control reacts to the current error, Integral control addresses past errors to eliminate steady-state errors, and Derivative control predicts future errors based on the rate of error change.

Why is it important to configure PID in a PLC?

-Configuring PID in a PLC is important because it allows for automated control of processes, improving response times and accuracy in maintaining desired outputs, such as temperature in a boiler.

What steps are involved in configuring a PID block in a Siemens S1200 series PLC?

-To configure a PID block in a Siemens S1200 series PLC, one must select a cyclic interrupt, drag and drop the PID compact block, assign input and output parameters, set control types, define process value limits, and tune PID parameters before downloading the configuration to the PLC.

What is the role of the temperature gauge in the control process described?

-The temperature gauge continuously measures the temperature of the process and provides feedback to the PID controller, allowing it to adjust the control output based on the difference between the measured temperature and the setpoint.

What happens to the control output when the input exceeds the setpoint?

-When the input exceeds the setpoint, the PID controller reduces the control output gradually to stabilize the process around the new desired setpoint.

How does the PID controller minimize errors?

-The PID controller minimizes errors by continuously adjusting the control output based on the calculated error, using the proportional, integral, and derivative terms to respond to current, past, and predicted future errors.

What is the significance of the cyclic interrupt in PID configuration?

-The cyclic interrupt allows for faster response times in PID control by enabling more frequent scans and adjustments, enhancing the control system's performance compared to standard scan cycles.

What type of feedback is necessary for a PID controller to function effectively?

-Continuous feedback from sensors, such as temperature transmitters, is necessary for a PID controller to function effectively, as it relies on this feedback to adjust the control output and maintain the desired setpoint.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführen5.0 / 5 (0 votes)