How To Turn Any Photo Into a Screen Print Using Halftones.

Summary

TLDRIn this tutorial, the creator demonstrates how to transform a regular photo into a detailed screen print design for t-shirts using halftones. The process involves preparing a screen with emulsion, converting the image to grayscale, and printing it onto transparency sheets. After exposing the image onto the screen, the creator prints the design onto shirts, offering tips on printer selection, screen mesh count, and halftone settings. The video also highlights different shirt designs, showcasing the photo-realistic results of halftone screen printing on various fabrics, including ringer tees and classic white t-shirts.

Takeaways

- 😀 Use grayscale and halftone techniques in Photoshop to turn a photo into a screen print-ready design.

- 😀 Ensure the screen you use for printing has a high mesh count (e.g., 305 or 230) for detailed designs.

- 😀 Use an inkjet printer (such as a Canon Pixma) to print the design onto transparency sheets for screen exposure.

- 😀 Adjust Photoshop’s bitmap settings to control the size of halftone dots, influencing print detail and clarity.

- 😀 Transparency sheets must be printed with the highest quality settings to achieve a crisp design.

- 😀 Apply emulsion to your screen, allow it to dry in a dark environment, and then burn the design using a lightbox.

- 😀 Test prints on scrap shirts before printing the final design to ensure accuracy and quality.

- 😀 A detailed design often requires higher mesh counts on the screen for the halftone dots to transfer cleanly.

- 😀 Red ink on white shirts (or ringer tees) can create visually striking designs, but adjustments can be made if necessary.

- 😀 Screen printing requires patience: allow time for drying and exposure steps to ensure successful results.

- 😀 Always consider the final product’s quality, ensuring your screens, prints, and designs are up to your desired standards before selling.

Q & A

What is the main goal of the tutorial?

-The main goal of the tutorial is to teach viewers how to transform a regular photo into a screen print using halftones, which can then be printed on shirts or other designs.

Why is halftone printing important in screen printing?

-Halftone printing is essential because it allows for the creation of detailed, photo-realistic prints by converting continuous-tone images (like photographs) into dots. This makes it possible to print complex images using only one color of ink.

What software is used to prepare the photo for screen printing?

-Photoshop is used to convert the photo to grayscale, then to bitmap, and to apply halftone dots. This process prepares the image for screen printing.

Why is it necessary to turn the image into grayscale before applying halftones?

-Turning the image into grayscale removes all color, making it easier to apply halftones and ensuring that the design is compatible with a single-color screen print.

What settings should be used when converting the image to a bitmap for halftones?

-In Photoshop, you should set the output to 300 pixels per inch (for a high-quality print) and use the halftone screen method. The angle can be adjusted based on personal preference, with the example in the video using 15 by 45 degrees.

What is the purpose of the transparency sheet in the process?

-The transparency sheet is used to print the halftone image, which will then be used to burn the image onto the screen during the exposure process. This allows the design to be transferred onto the screen for printing.

How does the mesh count of the screen affect the print quality?

-The mesh count determines the detail level of the print. A higher mesh count (like 305) allows for finer details and sharper prints. The creator mentions using a 230 mesh count, which still works but may not capture the finest details.

What are the key steps in preparing the screen for printing?

-The screen is coated with emulsion, left to dry in a dark environment, and then exposed to light with the transparency sheet placed on top. After exposure, the screen is washed to reveal the design.

What is the advantage of using a Canon Pixma printer for screen printing?

-The Canon Pixma printer is affordable, reliable, and supports printing on larger sizes (up to 11 by 17 inches), which is ideal for creating transparency sheets that can cover a larger screen area.

What is the significance of the test print in the screen printing process?

-The test print allows the creator to check the quality of the design, ensure that it has transferred correctly from the screen, and assess the color choice (e.g., red ink) before printing on the final shirts.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

DIY: How To Burn a Silkscreen and Print at Home

Cara Menggunakan Mesin Press Sablon Kaos Buat Usaha Sablon Baju dari Pemula Sampai Expert

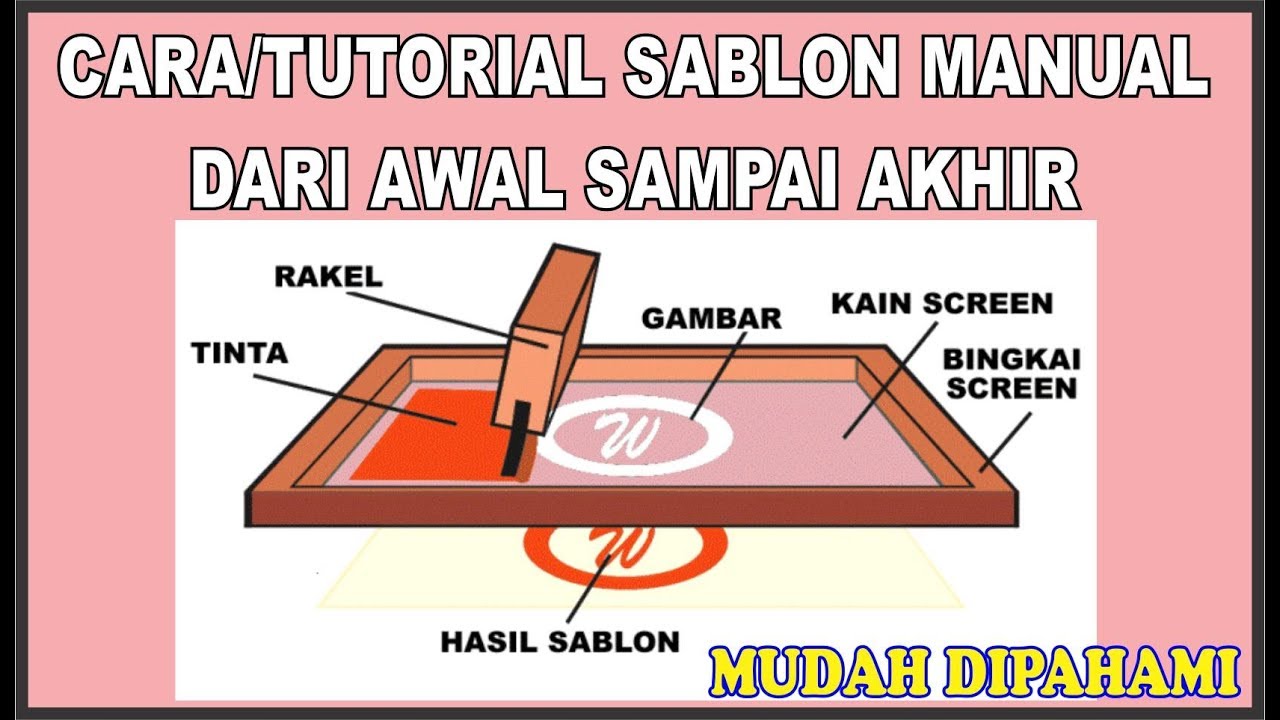

SABLON KAOS MANUAL PRAKTIS DARI AWAL HINGGA AKHIR DIJAMIN BISA

Membuat Desain Tipografi Simpel

Creating Illustrated 1980s Vintage Tees in Photoshop

Why You Should Avoid Using Teespring for Print on Demand

5.0 / 5 (0 votes)