What is a Load Sensing Pump?

Summary

TLDRThis video provides a concise introduction to load sensing pumps, explaining their unique flow compensating mechanism. Unlike pressure compensated pumps, load sensing pumps adjust their outlet pressure based on the load's needs, ensuring efficient operation with minimal energy use. The system maintains a steady speed for hydraulic cylinders, regardless of changes in load, by using feedback from the load to adjust the pump's pressure. This ensures optimal performance and avoids fluctuations in speed. The video also introduces Lunchbox Sessions’ interactive resources to explore hydraulic concepts hands-on.

Takeaways

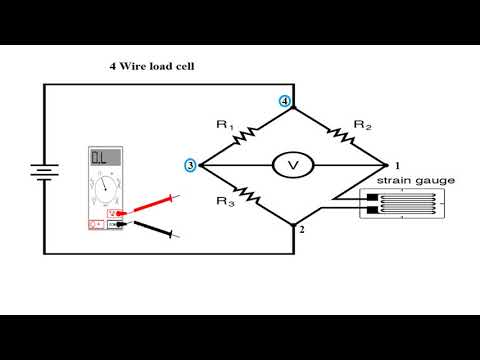

- 😀 Load sensing pumps, also known as flow compensating pumps, have both a pressure compensator and a load sensing adjustment.

- 😀 The pressure compensator regulates high-end pressure to protect the system, while the flow compensator adjusts based on load feedback.

- 😀 The flow compensator receives pressure feedback directly from the load (e.g., hydraulic cylinder) to adjust pump performance.

- 😀 In the example, the load pressure is 300 PSI, and this pressure is fed back to the pump controller, influencing the flow compensator's setting.

- 😀 The combined pressures from the load and the spring setting result in a regulated pump outlet pressure, ensuring system efficiency.

- 😀 Unlike a pressure compensated pump, which maintains a fixed pressure (e.g., 2,000 PSI), a load sensing pump adjusts its outlet pressure based on the load.

- 😀 The system ensures that the pump outlet pressure is only slightly higher than what’s needed by the load, minimizing energy consumption.

- 😀 A needle valve controls the cylinder stroke speed by regulating the flow, helping maintain steady operation even under varying loads.

- 😀 When a brick is added to the load, the pressure increases from 600 PSI to 900 PSI, but the system maintains a 300 PSI differential, ensuring stable operation.

- 😀 The system automatically adjusts to maintain a consistent cylinder speed, preventing fluctuations when the load changes (e.g., adding or removing bricks).

- 😀 Load sensing systems are energy-efficient as they adjust the pump’s pressure to match the load requirements, reducing waste and improving system performance.

Q & A

What is the primary function of a load-sensing pump?

-The primary function of a load-sensing pump is to automatically adjust its outlet pressure based on the load's requirements, ensuring efficient operation by supplying only the necessary pressure to the system.

How does the flow compensator in a load-sensing pump work?

-The flow compensator receives feedback from the load (such as a hydraulic cylinder) and adjusts the pump’s outlet pressure to match the load's needs, ensuring that pressure is always optimized without wasting energy.

What is the difference between a load-sensing pump and a pressure-compensated pump?

-A load-sensing pump adjusts its outlet pressure based on the load's feedback, whereas a pressure-compensated pump maintains a constant high pressure regardless of the load, leading to higher energy consumption.

What role does the pressure compensator play in a load-sensing pump?

-The pressure compensator is responsible for limiting the maximum pressure in the system, ensuring that the pump does not exceed the desired pressure and protecting the system from damage.

What is the 300 PSI margin pressure in a load-sensing pump system?

-The 300 PSI margin pressure refers to the constant differential pressure maintained between the load pressure and the pump outlet pressure. This ensures that the system operates efficiently and smoothly.

How does the pump adjust its outlet pressure when the load increases?

-When the load increases, such as when more bricks are added to the stack, the pump automatically adjusts its outlet pressure to maintain the 300 PSI differential, ensuring that the system continues to function smoothly without speed fluctuations in the hydraulic cylinder.

Why is maintaining a steady cylinder speed important in hydraulic systems?

-Maintaining a steady cylinder speed is crucial to ensure consistent performance, avoid system instability, and prevent unnecessary wear on the equipment. Load-sensing pumps help achieve this by adjusting to changes in load without affecting the speed.

What happens when the load pressure rises in a load-sensing pump system?

-When the load pressure rises, the pump automatically increases its outlet pressure to maintain the desired differential pressure, ensuring that the hydraulic system adapts to the increased load without affecting the performance.

How does the load-sensing pump avoid wasting energy?

-The load-sensing pump avoids wasting energy by only supplying the exact amount of pressure needed for the load, rather than maintaining a constant high pressure, which would require more energy.

What is the significance of the needle valve in the load-sensing pump system?

-The needle valve is used to control the cylinder stroke speed by regulating the flow of hydraulic fluid. It works in conjunction with the load-sensing pump to maintain a steady and controlled speed despite changes in load.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

5.0 / 5 (0 votes)