Manajemen Produksi dan Operasi (Pengantar Bisnis)

Summary

TLDRThis video covers the topic of operations and production management, focusing on key concepts such as the definition of operations management, scope, factory location determination, inventory control, and quality supervision. It highlights the importance of managing resources effectively and efficiently to produce goods and services. The script also delves into expert definitions and the scope of production management, touching on production systems, workforce management, cost control, and the vital role of information systems. Key factors in selecting factory locations and maintaining quality standards are also discussed, emphasizing their significance in achieving business success.

Takeaways

- 😀 Production involves activities aimed at helping companies produce goods by transforming resources into products and services.

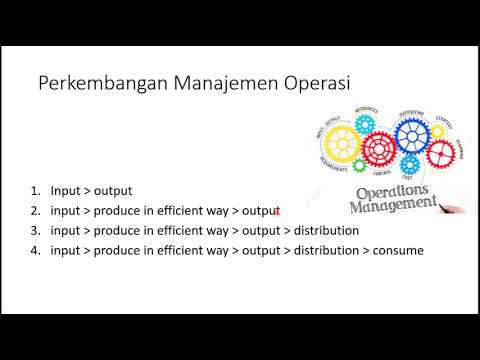

- 😀 Operations management focuses on converting inputs (human, material, capital) into goods and services efficiently.

- 😀 According to experts, production and operations management is about coordinating resources effectively to create utility (value) for goods and services.

- 😀 The scope of production and operations management includes designing systems, managing inventory, maintaining equipment, managing workforce, controlling costs, and overseeing production processes.

- 😀 Design of production systems ensures activities are directed towards achieving efficient and effective production outcomes.

- 😀 Control of production and operations ensures activities align with the plans and corrects any deviations that occur during the process.

- 😀 Effective inventory management is crucial for smooth production by ensuring adequate stock levels and preventing disruptions.

- 😀 Machine and equipment maintenance is essential to keep production systems running smoothly without unexpected breakdowns.

- 😀 Workforce management is integral, as skilled labor is crucial for maintaining operational efficiency in production systems.

- 😀 Cost control ensures resources like materials, time, and labor are used effectively to avoid inefficiency and keep expenses under control.

- 😀 The decision on factory location is influenced by factors such as proximity to customers, suppliers, transportation infrastructure, available workforce, government policies, and climate conditions.

Q & A

What is the main focus of operational and production management?

-The main focus of operational and production management is to organize and coordinate the use of resources effectively and efficiently to produce goods and services, ensuring smooth production processes and achieving company goals.

How do experts define production and operational management?

-Experts define production management as the process of coordinating human, material, and financial resources to produce goods or services. Operational management is the specific area that transforms these resources into finished products and services.

What is the role of the production system design in operational management?

-The production system design ensures that the production activities are properly planned and aligned with the objectives of the company, promoting efficiency and effectiveness in achieving production goals.

Why is inventory control important in production management?

-Inventory control is essential in ensuring that the necessary materials are available for production without overstocking, which can lead to unnecessary costs. It helps maintain a balance between supply and demand, contributing to smooth production processes.

What are the key factors influencing the location of a manufacturing plant?

-Key factors influencing plant location include proximity to customers, transportation facilities, availability of skilled labor, infrastructure, government policies, proximity to suppliers, and climate conditions.

What is the difference between order-based production and inventory-based production?

-Order-based production is a reactive strategy where production is triggered when a customer order is received, while inventory-based production is proactive, aiming to produce goods based on forecasts to maintain stock levels for future demand.

How does labor management affect the success of production and operations?

-Labor management is crucial because skilled and well-trained workers contribute to efficient production and smooth operations. Proper management ensures that the workforce is effectively utilized, enhancing overall productivity.

What role does machine and equipment maintenance play in production management?

-Maintenance ensures that machines and equipment are always in good working condition, preventing production delays and reducing the risk of equipment breakdowns, which can disrupt production schedules.

What is the purpose of quality control in operational management?

-The purpose of quality control is to ensure that products and services meet the required standards and satisfy customer expectations. This involves monitoring factors such as performance, reliability, and maintenance of products.

What is the importance of cost control in production and operations?

-Cost control is important to manage and minimize expenses related to materials, labor, and equipment usage. It helps improve efficiency by ensuring that resources are used effectively without unnecessary waste, contributing to the profitability of the company.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآن5.0 / 5 (0 votes)