Black Oxide: The Simple and Powerful Way to Transform Your Hardware

Summary

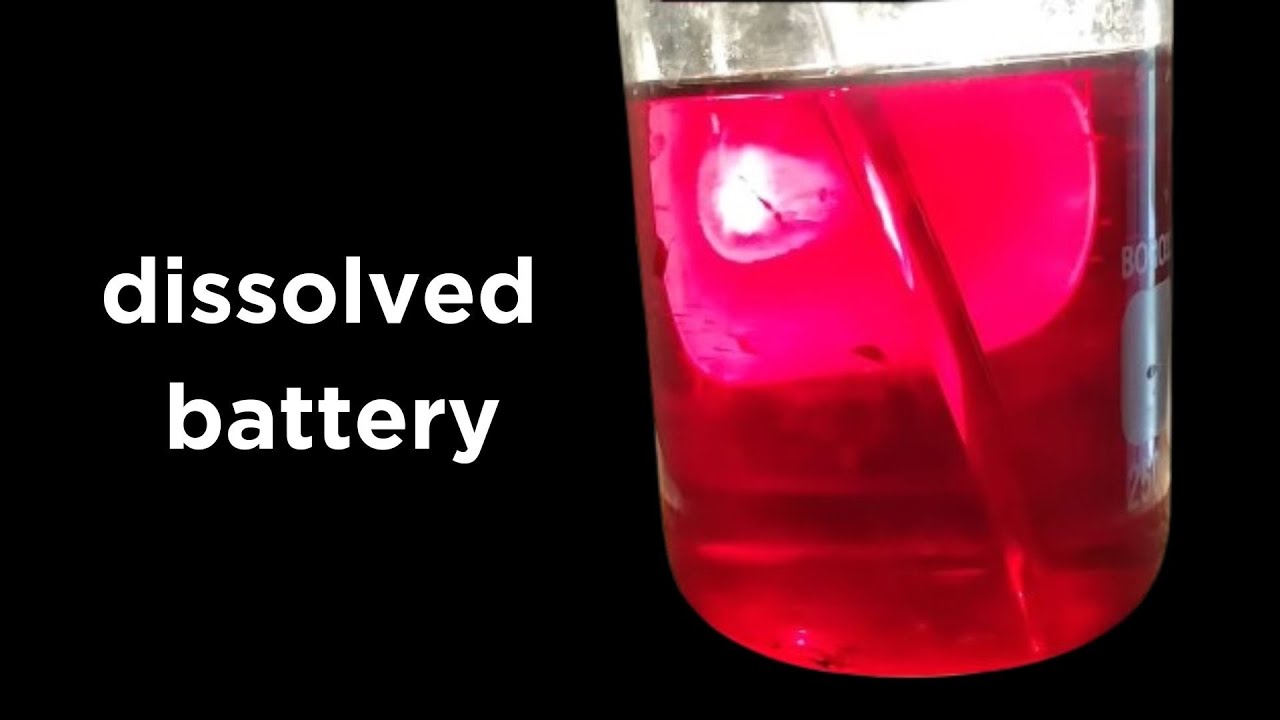

TLDRIn this video, the host demonstrates how to restore rusty bolts using a black oxide coating process. This method provides a durable, chip-resistant finish without painting. The process involves cleaning the bolts by sandblasting or using a wire wheel, then treating them with a black oxide solution. After soaking in the solution, the bolts are coated with penetrating oil to prevent rust. The technique works for steel bolts but not for stainless steel or aluminum. It's a cost-effective way to refurbish bolts, perfect for restoration projects.

Takeaways

- 🔧 The video demonstrates how to restore rusty bolts using a black oxide coating process.

- 🧪 Black oxide coating is a chemical process, not paint, and won't chip off like paint would.

- 🧴 The process involves using a Caswell black oxide treatment concentrate mixed with distilled water in a 1:9 ratio.

- 🔨 The bolts need to be cleaned first, removing rust and grime via sandblasting or a wire wheel.

- 🧼 After cleaning, the bolts are soaked in acetone to remove oils and other contaminants.

- 🕑 The black oxide treatment works after soaking the bolts for 5-10 minutes, though longer times may also work.

- 🧲 A magnet can be used to retrieve the bolts from the solution without breaking glass jars.

- 💡 This method does not work on stainless steel or aluminum bolts, only regular steel.

- 🛡️ After treatment, the bolts are coated with Caswell penetrating oil to prevent future rusting.

- 🔩 The process can be applied to various small parts like springs and washers, giving them a clean, factory-new appearance.

Q & A

What is black oxide coating and how does it differ from painting?

-Black oxide coating is a chemical process used to coat metal parts like bolts. Unlike paint, it won’t chip off and is more durable. It chemically bonds with the metal surface, whereas paint sits on top.

What materials are required to perform the black oxide coating process at home?

-You need Caswell black oxide treatment concentrate, distilled water, a container to mix the solution, acetone, a sandblast cabinet (or a wire wheel for cleaning), a magnet, and penetrating oil.

How do you mix the black oxide treatment solution?

-The black oxide treatment is mixed at a ratio of one part black oxide concentrate to nine parts distilled water.

What is the purpose of sandblasting the bolts before applying the black oxide treatment?

-Sandblasting removes rust, grime, and paint from the bolts to ensure they are clean, which is essential for the black oxide coating to bond properly to the metal surface.

Why should acetone be used after sandblasting the bolts?

-Acetone is used to remove any oil or residue left on the bolts after sandblasting, ensuring the surface is clean for the black oxide treatment.

Does black oxide coating work on all types of metal?

-No, black oxide coating does not work on stainless steel or zinc-coated bolts, and it likely doesn’t work on aluminum either. It's designed specifically for regular steel.

How long should bolts be left in the black oxide solution?

-The bolts should be left in the black oxide solution for about five to ten minutes, although longer durations (up to an hour) won’t cause harm but also won’t significantly improve the results.

Why do the bolts sometimes have light spots after the black oxide treatment?

-Light spots can appear if some areas were not fully cleaned or if any zinc or leftover paint remained on the bolt, which prevents the black oxide from adhering.

What is the purpose of applying penetrating oil after the black oxide process?

-The penetrating oil protects the bolts from rusting by sealing the surface after the black oxide coating. Over time, it soaks into the surface, creating a semi-gloss or satin finish.

Is the black oxide process expensive to start, and how long do the materials last?

-The initial setup cost can be somewhat expensive, but the black oxide treatment and penetrating oil last for a long time. Hundreds of bolts can be treated without using up much of the supplies.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

5.0 / 5 (0 votes)