#7 Karir dan Profesi : Perancangan Proses Produksi (S1 T.Industri, Kelas 1) - SEG 3

Summary

TLDRThis transcript discusses the concept of added value in the production process, focusing on ways to reduce waste and improve efficiency through methods like value engineering and value management. Experts discuss the importance of customer value, the role of systems thinking, and how businesses can enhance their products and services while managing costs effectively. They highlight the significance of long-term planning, quality management, and competitive strategies, especially for small and medium enterprises. The conversation also provides practical advice for students in industrial engineering to succeed in the industry by mastering management systems and continuous learning.

Takeaways

- 😀 Added value in production refers to the increase in worth of raw materials as they go through various processes to become finished products.

- 😀 Value engineering is a systematic method aimed at improving product value by reducing unnecessary costs while maintaining or improving functionality.

- 😀 Customer value is the balance between the benefits provided by a product and its cost, including factors like service quality and waiting time.

- 😀 Companies should focus on optimizing their value chain from suppliers to customers, ensuring efficiency in each step of the process.

- 😀 Long-term planning and risk management are essential for businesses to stay competitive and prepared for future challenges.

- 😀 The primary goal of value engineering is to maximize customer satisfaction while minimizing costs through careful analysis of production processes.

- 😀 Continuous learning and skill development are vital for students and professionals to remain competitive in their industries.

- 😀 Systems thinking is crucial for understanding the entire flow of production, from inputs to outputs, ensuring that all processes are interconnected and efficient.

- 😀 Value management (or value engineering) encourages businesses to assess and enhance their offerings based on customer perspective rather than just internal production costs.

- 😀 Modern management focuses on creating customer value through quality service, competitive pricing, and time efficiency, rather than merely focusing on the product itself.

- 😀 Students are encouraged to master both systems thinking and management skills like PDCA (Plan-Do-Check-Act) to prepare for successful careers in industrial engineering.

Q & A

What is the definition of added value in production?

-Added value is the comparison between the output value and the input value. It refers to the value added to goods or services during a production process, transforming raw materials into finished products and adding incremental value through various stages.

How can businesses reduce waste in production while adding value?

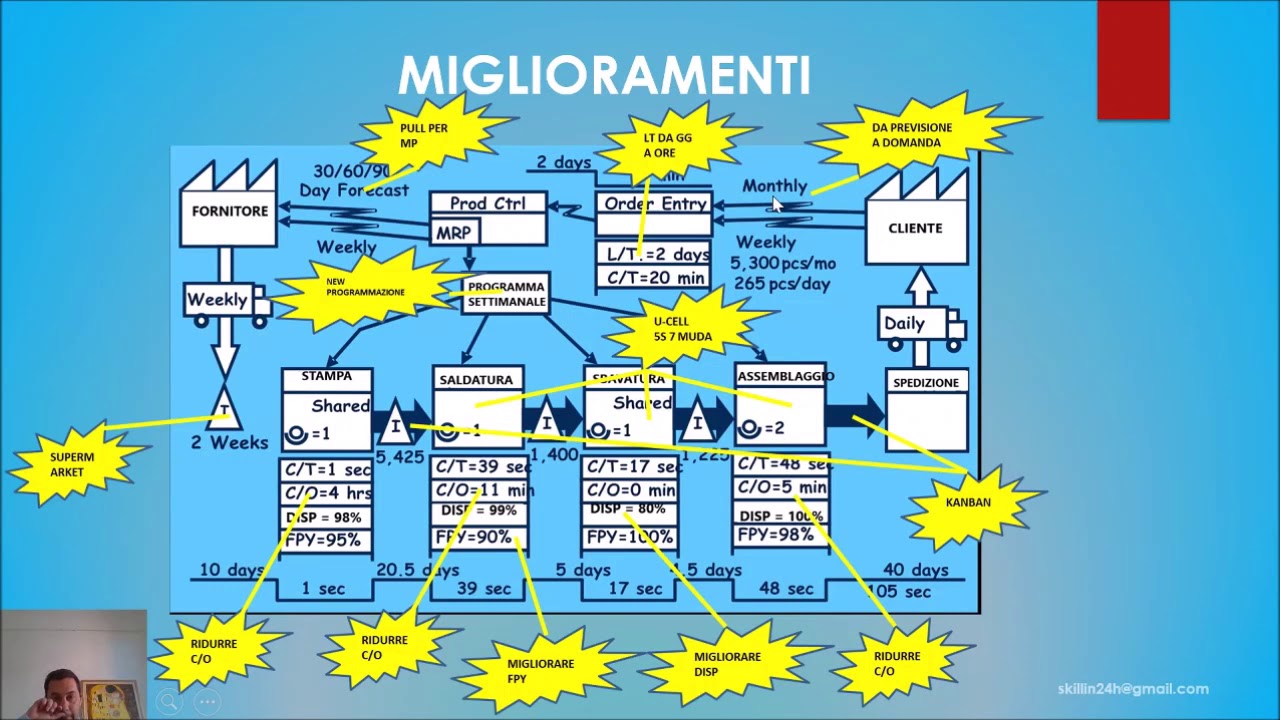

-Businesses can reduce waste by streamlining the production process, eliminating inefficiencies, and focusing on minimizing unnecessary steps. This includes evaluating the production process, utilizing value engineering techniques, and improving the use of resources to ensure value is added at each stage.

What is the concept of value engineering, and how does it apply to production?

-Value engineering is a systematic method used to increase the value of a product or service by improving its function and reducing costs without compromising quality. In production, it helps identify areas for improvement, ensuring that processes are efficient and costs are minimized while maximizing customer value.

Why is customer satisfaction important in the context of value engineering?

-Customer satisfaction is central to value engineering because the ultimate goal is to create products or services that meet or exceed customer expectations. By focusing on improving both the functionality and cost-effectiveness of a product, businesses can enhance customer value, leading to greater satisfaction and loyalty.

What are the key components that make up customer value?

-Customer value consists of the product's quality, the service provided, and the price paid by the customer. It also includes additional factors such as waiting time, convenience, and emotional factors like pride or satisfaction from the purchase.

How can a company maximize added value with limited resources?

-A company can maximize added value with limited resources by implementing value engineering techniques, focusing on optimizing the efficiency of its production processes, and strategically managing its resources. This involves reducing waste, improving quality, and continuously enhancing the customer experience without exceeding the available resources.

What role does production process planning play in increasing added value?

-Production process planning is crucial for increasing added value as it ensures that every step of the production is optimized for efficiency. Proper planning helps reduce waste, minimizes costs, and ensures that the process moves smoothly from one stage to the next, adding value at each point.

What is the importance of 'systems thinking' in industrial engineering and production planning?

-Systems thinking is important because it allows individuals to see the entire production process as an interconnected system, where each part affects the whole. This holistic approach helps identify inefficiencies, optimize processes, and ensure that inputs, processes, and outputs work together to maximize value.

How does value engineering contribute to minimizing internal and external failures in production?

-Value engineering helps minimize both internal and external failures by focusing on improving the product’s functionality and identifying potential issues before they become problems. It ensures that the product meets customer expectations and reduces the likelihood of costly errors or dissatisfaction.

What advice is given to students in the industrial engineering field regarding production process planning?

-Students are encouraged to master systems thinking, focus on learning management techniques like PDCA (Plan-Do-Check-Act), and understand the importance of continuous improvement. The advice emphasizes the need to apply these concepts in real-world scenarios to be successful in the field of industrial engineering.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Apa itu SEVEN WASTE (7 Pemborosan)

#7 Karir dan Profesi : Perancangan Proses Produksi (S1 T.Industri, Kelas 1) - SEG 2

ムダ取りの必要性【アニメで学ぶムダ取り入門:Lesson1】

MPB 6_1 Analisis Nilai Tambah

Gestão da Produção (Aula #01 - Conceitos mais utilizados na Produção)

Lezione 4D - CREAZIONE VSM - Parte 4 di 4 - Lean Thinking e Toyota Producition System - Zero sprechi

5.0 / 5 (0 votes)