ムダ取りの必要性【アニメで学ぶムダ取り入門:Lesson1】

Summary

TLDRThis course introduces the concept of eliminating waste in production processes to increase profits and improve workplace efficiency. It emphasizes the importance of recognizing waste from the customer's perspective, focusing on activities that add value. The script explores how waste arises from both ignorance and a sense of complacency, and outlines strategies to reduce unnecessary work. It also highlights the barriers to waste elimination, such as ingrained beliefs and emotional resistance. By understanding value-added work and reducing non-valuable tasks, organizations can enhance profitability, customer satisfaction, and employee morale.

Takeaways

- 😀 Waste is anything that does not add value to the customer and should be eliminated to improve productivity and profits.

- 😀 Added value is defined as work that benefits the customer, while non-value work is considered waste.

- 😀 It's essential to view waste from the customer's perspective, as work that may be necessary internally may not be valuable to the customer.

- 😀 The key to increasing profits is to reduce total depreciation, primarily through reducing manufacturing costs and improving operational efficiency.

- 😀 Waste arises from two main factors: a sense of undermining (believing the current way is the best) and ignorance (lack of knowledge on how to identify and deal with waste).

- 😀 The elimination of waste leads to better employee motivation, increased productivity, and enhanced customer satisfaction.

- 😀 Companies can improve profits by reducing labor, material costs, and other unnecessary expenses in the manufacturing process.

- 😀 Waste elimination is essential in creating a profitable workplace and improving work conditions.

- 😀 Barriers to waste elimination include resistance to change, emotional reactions, and cultural factors like a preference for tradition or a lack of openness to new ideas.

- 😀 The three categories of work are: value work (directly adds value), auxiliary work (necessary but non-productive), and waste (should be eliminated immediately).

- 😀 Eliminating high-level waste (like unnecessary movement or defects) is crucial for enhancing efficiency in production and leading to greater profits.

Q & A

What is the primary goal of the course discussed in the script?

-The primary goal of the course is to introduce the concept of eliminating waste in production activities, which not only increases profits but also improves workplace capabilities and working conditions.

What are the two main factors that cause waste, according to the script?

-The two main factors that cause waste are a sense of undermining (the belief that things must be done a certain way or are efficient) and ignorance (not knowing what waste is or how to identify it).

What is meant by 'added value' in the context of waste elimination?

-Added value refers to work that is valuable to the customer, as opposed to work that is unnecessary or irrelevant to the customer, which is considered waste.

How is waste categorized from the customer’s perspective?

-From the customer's perspective, work can be divided into added value (valuable to the customer), clear waste (unnecessary for both the organization and the customer), and waste from the customer’s perspective (work that, although necessary internally, is not valuable to the customer).

What is the importance of recognizing waste from the customer's perspective?

-Recognizing waste from the customer's perspective is crucial because the customer pays for added value. Even if a task is necessary for the organization, it may not be valuable to the customer, thus it should be considered waste.

What are the three ways to increase profits according to the script?

-The three ways to increase profits are by increasing sales value, decreasing total depreciation, or doing both. However, increasing sales value is influenced by customer needs, so the focus often shifts to reducing depreciation.

What types of costs contribute to manufacturing costs?

-Manufacturing costs include direct labor costs (money spent on people), direct expenses (money spent on materials like electricity and gas), and indirect manufacturing costs.

What are the three categories of work mentioned in the script?

-The three categories of work are value work (which leads to added value and generates profits), ancillary work (necessary but not directly adding value), and waste (which does not contribute to value and should be reduced).

What is the significance of 'high-level waste' in waste elimination activities?

-High-level waste refers to ancillary work and waste, which are non-value-adding activities that should be reduced in waste elimination efforts.

What barriers prevent waste elimination, as outlined in the script?

-Barriers to waste elimination include barriers in consciousness (e.g., being insensitive to change), emotion (e.g., being quick to deny or give up), and culture (e.g., disliking change or not listening). These barriers hinder the process of eliminating waste and improving efficiency.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Apa itu SEVEN WASTE (7 Pemborosan)

Learn What Standard Work is Within a Lean Manufacturing System

3 5s Orientation Part 1

Os 7 desperdícios do Lean

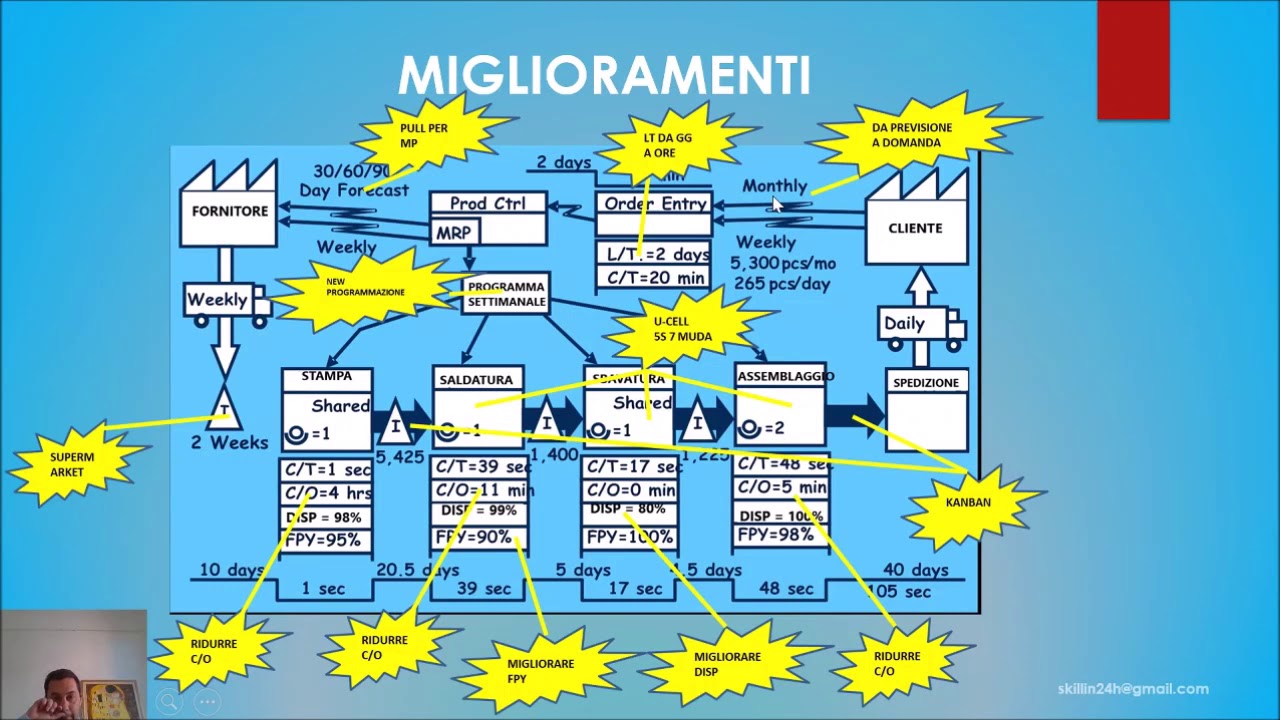

Lezione 4D - CREAZIONE VSM - Parte 4 di 4 - Lean Thinking e Toyota Producition System - Zero sprechi

Lean Six Sigma In 8 Minutes | What Is Lean Six Sigma? | Lean Six Sigma Explained | Simplilearn

5.0 / 5 (0 votes)