y2mate com amazin automation solution pvt ltd sPN4o9pBA 1080p

Summary

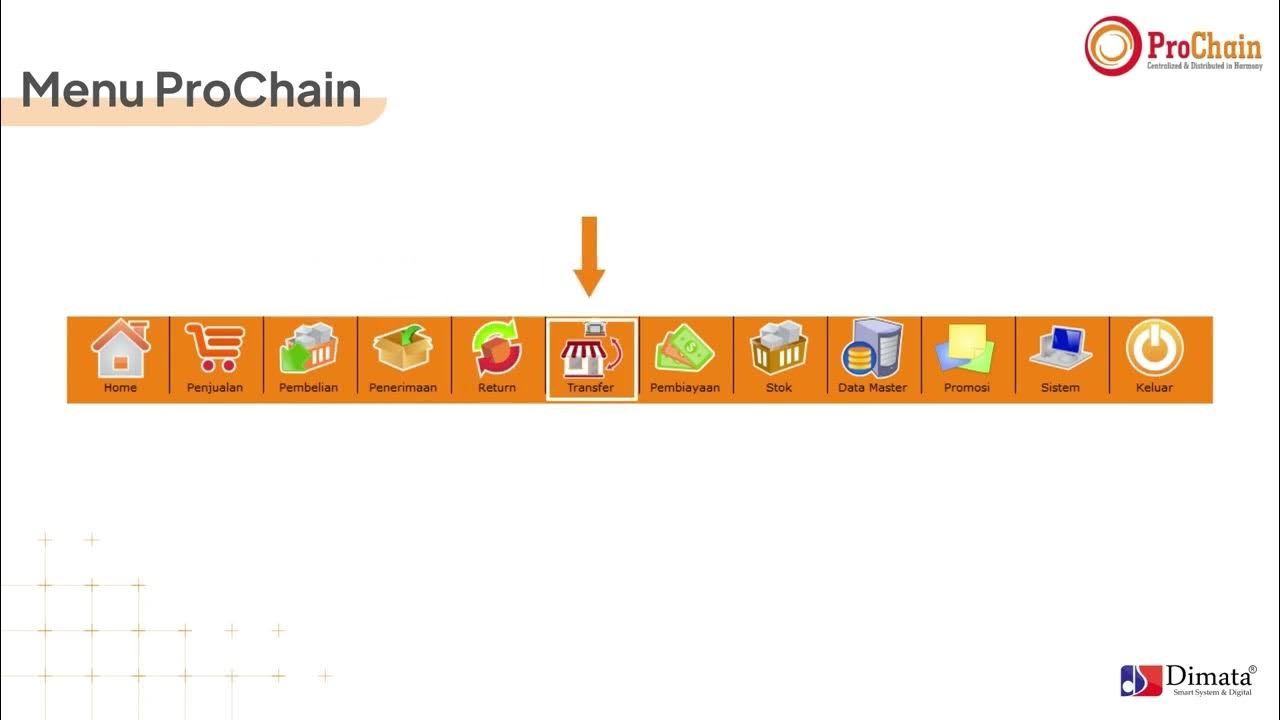

TLDRThe transcript discusses an innovative logistics management system (BLMS) used in Amazon’s operations, focusing on patching, flow control, and automation across manufacturing plants. It highlights productivity enhancements through machine tool logistics and automated processes, such as traffic light control, license plate recognition, and plant security. The system also ensures information security and optimizes various operational areas, including the loading process. Additionally, it mentions the use of engineering software for efficient plant management and outlines the roles of engineers and customers in maintaining a streamlined workflow.

Takeaways

- 😀 The BMS (Blond Logistics Management System) is an innovative logistics and flow control system used by Amazon.

- 😀 The BMS helps automate various functions across plants and manufacturing units to enhance productivity.

- 😀 It offers automatic patching and logistics flow management, aiming to streamline operations.

- 😀 The system includes a review system that monitors operational practices and machine tool logistics.

- 😀 BMS integrates with traffic light control and license plate recognition cameras to boost security and efficiency.

- 😀 The system is designed to work within different functional areas of plants, ensuring operational automation.

- 😀 The BMS system validates operational performance and offers reports on progress and efficiency.

- 😀 It incorporates safety features like traffic light control and installation of cameras to enhance operational security.

- 😀 The BMS system helps in managing complex logistics, improving both operational flow and hardware positioning.

- 😀 The planned deployment of the BMS system is scheduled for a future date, with continued developments in integration and performance monitoring.

Q & A

What is the purpose of the Blond Logistics Management System (BLMS)?

-The Blond Logistics Management System (BLMS) is an innovative logistics and flow control system designed to enhance productivity and automate various functional areas of manufacturing plants, including material science, operations, and plant management.

How does BLMS contribute to the automation of manufacturing processes?

-BLMS automates several operations within manufacturing plants, including tracking the movement of materials, controlling logistics flow, and managing machine tools, thereby improving overall productivity and efficiency.

What are some key features of the BLMS system mentioned in the script?

-Key features of BLMS include automatic operation management, integration of logistics systems, priority-based decision-making, video-based security features, and the ability to control hardware positioning and traffic light systems.

What role does video-based priority play in the BLMS system?

-Video-based priority within the BLMS system is used to assess and manage operations, ensuring that key processes are prioritized based on video inputs, which can include surveillance or monitoring of logistics flows.

How does BLMS improve security within a manufacturing plant?

-BLMS enhances security by integrating technologies such as license plate recognition cameras and traffic light control systems, helping to monitor and secure access points while improving operational efficiency.

What is the significance of the BLMS system’s integration with business operations?

-BLMS integrates with business operations to streamline various processes such as logistics management, plant automation, and customer communications, ensuring that the manufacturing system functions smoothly and efficiently.

What is meant by the 'operation twist management' in the context of BLMS?

-Operation twist management refers to the handling and adjustment of operational parameters within the BLMS to optimize the flow of materials and logistics, ensuring smooth transitions and minimal disruptions in the manufacturing process.

What types of hardware are involved in the BLMS system?

-Hardware involved in the BLMS system includes traffic light control systems, license plate recognition cameras, and other automation tools that help manage and secure plant operations.

What role do engineers and customers play in the implementation of BLMS?

-Engineers are responsible for the design and implementation of BLMS within the plant, while customers benefit from improved operations and communication through the system's automation and logistics enhancements.

How does BLMS impact the efficiency of loading operations?

-BLMS improves loading operations by automating various steps, ensuring the process is efficient and secure, and integrating advanced features such as video surveillance and traffic control systems.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级5.0 / 5 (0 votes)