A level Business Revision - Inventory Control

Summary

TLDRThis video explains the concept of stock or inventory control for A-level business students, focusing on key terminology like maximum stock, buffer stock, reorder levels, lead times, and reorder quantities. The tutorial covers the advantages of maintaining high stock levels, such as handling unexpected demand and ensuring production continuity, versus the benefits of keeping low stock levels, such as reducing costs and minimizing risks of breakages or theft. The video helps students understand how these concepts are crucial for managing inventory effectively and preparing for exams.

Takeaways

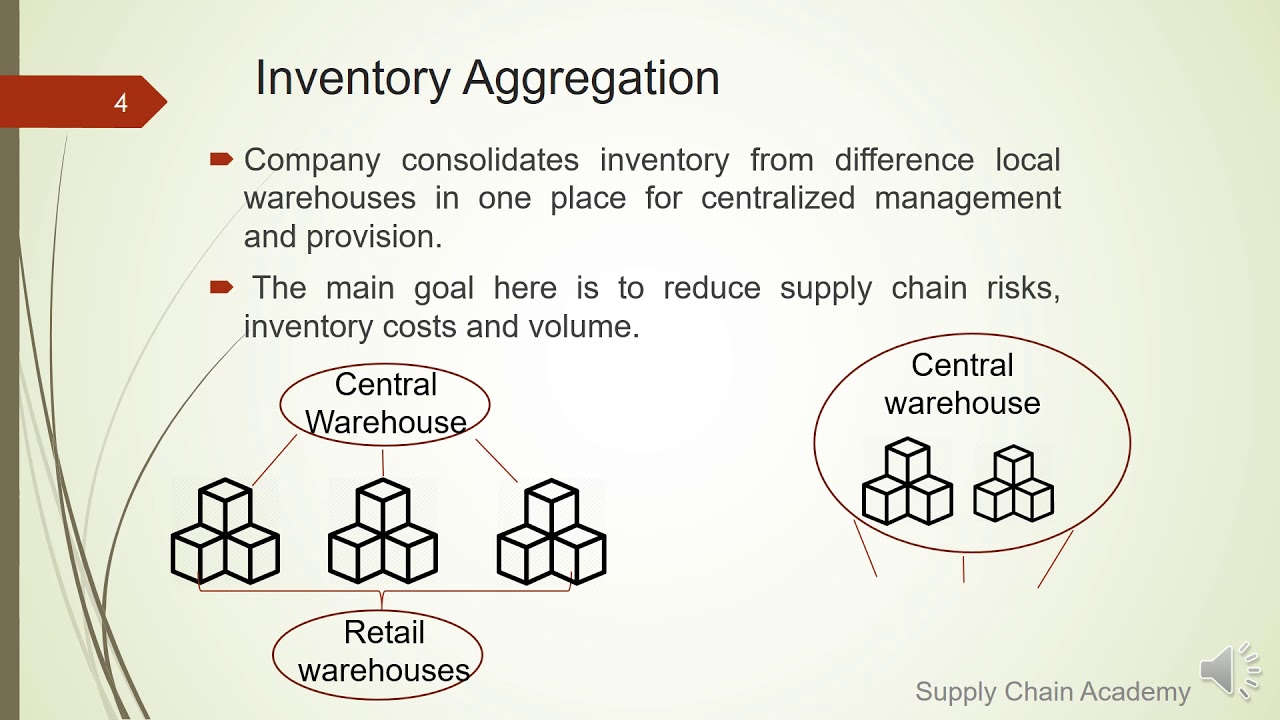

- 😀 Inventory control is crucial for businesses to manage stock efficiently and avoid stockouts or excess inventory.

- 😀 The x-axis of an inventory control diagram represents time, while the y-axis shows the level of stock.

- 😀 The maximum stock level is the highest amount of stock a business decides to keep, while the minimum level (buffer stock) ensures they never run out.

- 😀 Reorder level is the stock threshold at which a business places an order to restock before reaching the buffer stock level.

- 😀 Lead time is the time taken for suppliers to deliver new stock after an order is placed.

- 😀 Reorder quantity is the amount of stock ordered each time, calculated by subtracting the buffer stock level from the maximum stock level.

- 😀 High stock levels allow businesses to meet unexpected customer demand and prevent production halts due to supply issues.

- 😀 Keeping higher stock levels also benefits businesses from economies of scale by purchasing in bulk and reducing per-unit costs.

- 😀 Low stock levels help businesses reduce storage costs and improve liquidity by freeing up cash that would otherwise be tied up in inventory.

- 😀 Managing low stock levels also reduces risks related to security (theft) and spoilage (for perishable items).

- 😀 Both high and low stock strategies have their advantages, so businesses must balance their approach based on their needs and the nature of their products.

Q & A

What is inventory control, and why is it important for businesses?

-Inventory control is the process of managing the stock or inventory of a business to ensure it has the right amount of products available at the right time. It is important because it helps businesses meet customer demand, reduce costs, and avoid stockouts or overstocking.

What are the key terms used in inventory control?

-The key terms in inventory control include Maximum Stock Level (the highest stock level a business wants to maintain), Minimum Stock Level (the lowest acceptable stock level, also called buffer stock), Reorder Level (the point when an order should be placed), Lead Time (the time it takes for a supplier to deliver the stock), and Reorder Quantity (the amount of stock ordered when the reorder level is reached).

How does the inventory control diagram work?

-The inventory control diagram tracks the stock level of a business over time, showing fluctuations between the maximum and minimum stock levels. It indicates when the business needs to place an order (reorder level) and how stock is replenished once it reaches the minimum level.

What is the significance of the reorder level in inventory control?

-The reorder level is crucial because it triggers the action of placing an order to replenish stock before it runs out. This ensures that the business maintains enough inventory to meet demand without running into stockouts.

What does lead time mean in the context of inventory management?

-Lead time refers to the period it takes for a supplier to deliver the stock after an order is placed. It is important for businesses to factor in lead time when determining reorder levels to prevent stockouts.

Why might a business choose to maintain high stock levels?

-A business may maintain high stock levels to better meet changes in customer demand, reduce the risk of stockouts, create a contingency plan in case of supplier delays, and take advantage of economies of scale by buying inventory in bulk.

What are the advantages of keeping low stock levels?

-The advantages of keeping low stock levels include lower storage costs, improved liquidity by freeing up cash tied in inventory, and reduced risk of losses due to damage, theft, or spoilage, especially for perishable goods.

What role does buffer stock play in inventory control?

-Buffer stock acts as a safety net for businesses, ensuring they never run out of stock completely. It is the minimum stock level a business maintains to prevent production halts and ensure the availability of products in case of unexpected demand or supply chain disruptions.

What are the disadvantages of maintaining high stock levels?

-The disadvantages of maintaining high stock levels include higher storage costs, greater risk of stock obsolescence, and the potential for tying up a significant portion of cash in inventory, which could otherwise be used for other business needs.

How can economies of scale benefit a business in terms of inventory management?

-Economies of scale benefit a business by allowing it to purchase inventory in larger quantities, which can reduce the cost per unit. This enables businesses to negotiate better prices with suppliers, lowering overall procurement costs.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

CONTOH PENYELESAIAN SOAL REORDER POINT

Managing Stock Explained | Bar Gate Stock Graphs, JIT, Procurement & Logistics

This NEW 1-Click AI Agent is INSANE! 🤯

Model Persediaan Probabilistik

Managing Your Inventory with ShipHero's Warehouse Management Software

Inventory Management Lesson 2/3 Placement and quantity calculations ENG

5.0 / 5 (0 votes)