Inventory Management Lesson 2/3 Placement and quantity calculations ENG

Summary

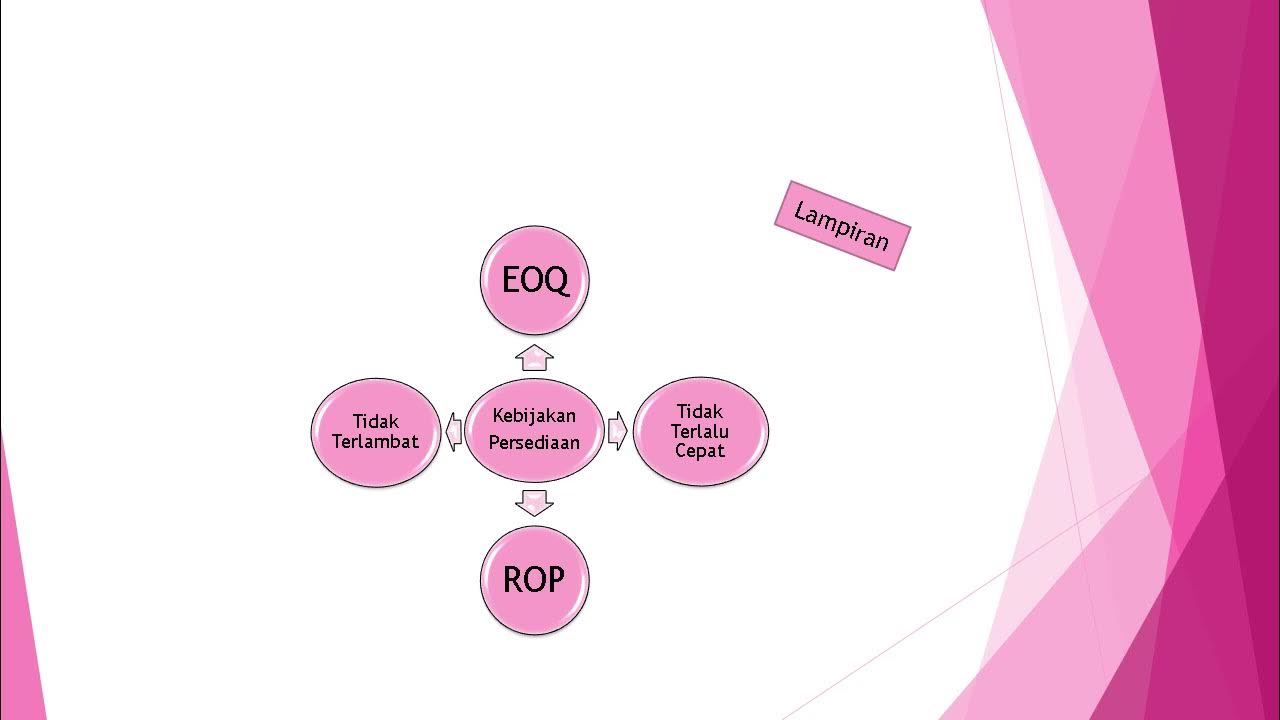

TLDRIn this lesson on inventory management, key concepts such as safety stock, economic order quantity (EOQ), and inventory aggregation are explored. Safety stock is defined as the minimum stock level to prevent shortages, while EOQ helps determine optimal order quantities based on demand and costs. The video also discusses inventory aggregation, which consolidates stock from various warehouses to minimize costs and risks. Different inventory management methods, including FIFO and LIFO, are highlighted, emphasizing their applicability based on product characteristics. Overall, the lesson equips viewers with essential strategies to enhance supply chain efficiency.

Takeaways

- 😀 Safety stock is the minimum inventory level that prevents shortages and ensures business continuity.

- 📊 The calculation of safety stock can be based on maximum daily usage and lead time.

- 📝 A simple method to calculate safety stock involves using historical usage data to estimate needs.

- 🔍 Economic Order Quantity (EOQ) optimizes order sizes based on cost and demand predictability.

- ⚖️ The EOQ formula incorporates ordering costs, demand, item value, and carrying costs.

- 📈 Example calculations show that understanding demand can lead to efficient inventory practices.

- 🏢 Inventory aggregation involves consolidating stock from multiple warehouses for cost efficiency.

- 💼 Managing inventory centrally can reduce costs associated with separate storage and staffing.

- 🍞 FIFO (First In, First Out) is crucial for managing perishable goods effectively.

- 🔄 LIFO (Last In, First Out) is better suited for non-perishable items that are not time-sensitive.

Q & A

What is safety stock and why is it important?

-Safety stock is the minimum level of inventory that a company maintains to prevent stockouts. It is important because it helps to reduce the risk of shortages and ensures that demand can be met consistently.

How is safety stock calculated using daily usage and lead time?

-Safety stock can be calculated by multiplying the maximum daily usage by the maximum lead time, and similarly, by multiplying the average daily usage by the average lead time. This gives a buffer against demand fluctuations.

What is the Economic Order Quantity (EOQ) model?

-The EOQ model is a formula used to determine the optimal order quantity that minimizes total inventory costs, considering factors like demand, ordering costs, and carrying costs.

Can you explain the formula for calculating EOQ?

-The EOQ formula is SQRT((2 * A * D) / (V * R)), where A is the ordering cost, D is the annual demand, V is the cost per item, and R is the carrying cost per dollar of inventory.

What are the benefits of inventory aggregation?

-Inventory aggregation consolidates stock from multiple locations into a single management system, which reduces costs, improves inventory control, and minimizes risks associated with having separate inventories.

What is the FIFO inventory management approach?

-FIFO, or First In, First Out, is an inventory management method where the oldest stock is sold or used first. This is particularly useful for perishable goods to prevent spoilage.

How does LIFO differ from FIFO?

-LIFO, or Last In, First Out, means that the newest inventory is sold or used first. This method is more applicable for non-perishable items that do not deteriorate quickly.

What is the significance of lead time in inventory management?

-Lead time is the time it takes for inventory to be replenished after an order is placed. It is crucial for calculating safety stock and determining order quantities to avoid stockouts.

How does demand predictability affect inventory management strategies?

-When demand is predictable, companies can use models like EOQ to determine optimal order quantities. Unpredictable demand may require higher safety stock levels to mitigate risks of stockouts.

Why should companies consider different approaches for calculating safety stock?

-Different businesses have unique demand patterns and operational complexities, so utilizing various approaches allows companies to better align their inventory management strategies with their specific needs.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Manajemen Persediaan (Inventory)

Model Inventori EOQ Deterministik (Pendahuluan)

Pertemuan 6 : Penentuan Tingkat Persedian (lanjutan)

OM (Practicum/Project) - Economic Order Quantity (EOQ)

SESI 14 MANAJEMEN PIUTANG DAN PERSEDIAAN

[PRESENTASI] TEKNIK PERSEDIAAN METODE JIT (JUST IN TIME) DAN EOQ (ECONOMIC ORDER QUANTITY)

5.0 / 5 (0 votes)