Example PLC: EATON EASY Intelligent Relay (Full Lecture)

Summary

TLDRThis video introduces viewers to the basics of programming a PLC (Programmable Logic Controller) using ladder logic. It covers system behavior based on push button inputs, with challenges that encourage viewers to predict outcomes and program the system. The tutorial explores programming using the EATON Easy 512 DCR intelligent relay, offering tips on navigating the PLC’s interface and using the Easy Soft programming software. The video emphasizes the importance of understanding the system’s functionality and verification techniques, urging viewers to practice for a better grasp of PLC programming.

Takeaways

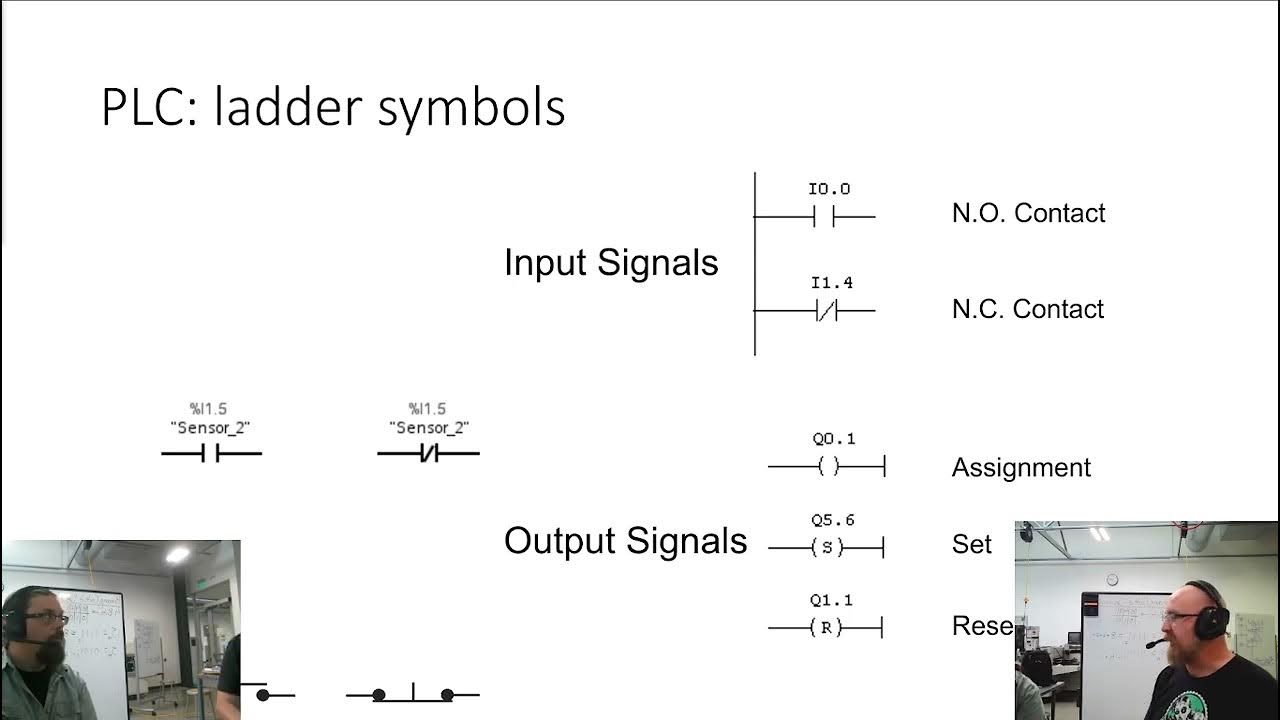

- 😀 The video introduces the concept of PLCs and their use in controlling various input and output devices.

- 😀 It demonstrates how push buttons (red and green) can control the energization of outputs and pilot lamps based on specific input combinations.

- 😀 The importance of understanding how a PLC interprets make and break functions is emphasized in programming logic.

- 😀 Challenge 1 involves predicting how a PLC would respond to inputs wired in series, using a ladder logic diagram.

- 😀 Challenge 2 focuses on understanding the response of a PLC when inputs are wired in parallel, and encourages programming to test expectations.

- 😀 The speaker highlights the need to think beyond simple input colors and consider how inputs are logically instantiated in a PLC program.

- 😀 Practical hints are provided, such as using alternate key presses to switch between make and break logic operations.

- 😀 The video introduces the Eat and Easy 512 DCR intelligent relay, a basic PLC model with a small LCD screen and specific buttons for programming.

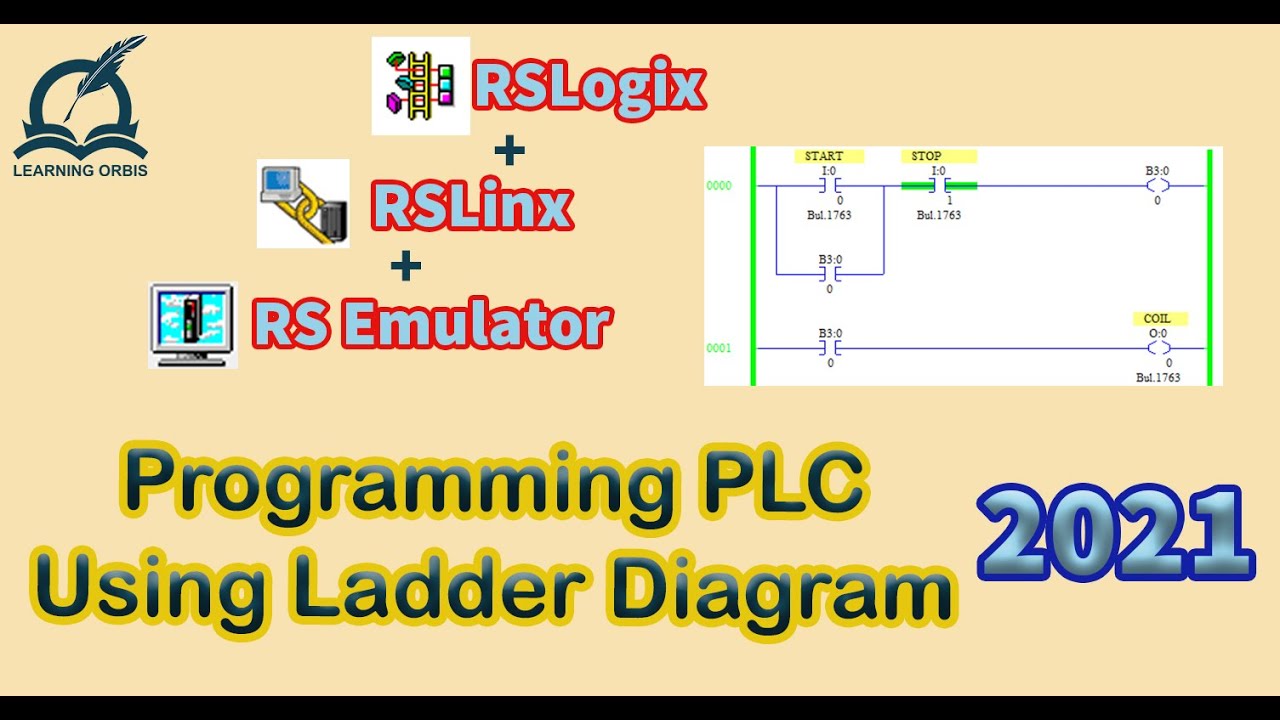

- 😀 Programming the PLC using dedicated buttons and proprietary keystrokes is shown, though a more user-friendly approach using Easy Soft software will be explored in later lessons.

- 😀 The importance of hands-on practice is emphasized, suggesting viewers program the PLC themselves to validate predictions and solidify their understanding.

- 😀 The video concludes by encouraging viewers to stay engaged with the series and review concepts regularly for better lab performance.

Q & A

What happens when no button is pressed in the described system?

-When no button is pressed, the output remains de-energized, and the first pilot lamp is off.

How does the system respond when the red push button is pressed alone?

-When only the red push button is pressed, the output remains de-energized, and the first pilot lamp is off.

What occurs when the green push button is pressed in the system?

-When the green push button is pressed, the output is energized, and the first pilot lamp comes on.

What happens if both the red and green push buttons are pressed simultaneously?

-When both the red and green push buttons are pressed together, the output remains de-energized, and the first pilot lamp is off.

What is the first challenge mentioned in the video?

-The first challenge is to predict how the system will respond based on the ladder logic diagram for all possible combinations of input, considering I2 is wired in series with I3.

What key concept does the first challenge focus on regarding the contacts in the PLC program?

-The first challenge focuses on understanding the make (closed) and break (open) functions of the contacts in the PLC program, particularly how they respond in their deactivated and activated states.

What is the second challenge mentioned in the script?

-The second challenge involves predicting how the system will behave when I2 is wired in parallel with I3, and how the system responds based on the ladder logic diagram for all possible input combinations.

What does the programming hint suggest for switching between make and break functions?

-The programming hint suggests pressing 'alternate' to switch between make and break logical operations of a contact.

How can you add wires to the PLC program according to the video?

-To add wires in the PLC programming environment, you press 'alternate' and use the arrow keys to draw wires. Press 'escape' to exit the wire-drawing mode.

What software is mentioned for easier PLC programming, and how does it compare to using the physical device?

-The video mentions Easy Soft programming software as a more user-friendly alternative to using the dedicated buttons and small LCD screen on the Eat and Easy PLC device.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

5.0 / 5 (0 votes)