Job, batch, flow and mass customization methods - Business Management - Teacher RK

Summary

TLDRIn this video, we explore four key production methods: job production, batch production, flow production, and mass customization. Job production is all about creating unique, one-of-a-kind products tailored to customer needs, like custom cakes or handcrafted furniture. Batch production involves creating identical products in batches, maximizing efficiency and cost savings, as seen in industries like automotive. Flow production focuses on smooth, continuous assembly lines for high-volume products, such as beverages. Finally, mass customization blends mass production with personal touches, allowing consumers to personalize standard products. Each method plays a vital role in shaping the products we use every day.

Takeaways

- 😀 Job production creates unique, one-of-a-kind products tailored to specific customer needs, like a custom wedding cake or handmade furniture.

- 😀 Batch production involves creating a set number of identical products before moving to the next batch, ensuring efficiency and cost savings.

- 😀 Flow production is a continuous process where products move seamlessly through each production stage, ideal for high-volume standardized goods.

- 😀 Mass customization combines the efficiency of mass production with the personal touch of customization, allowing customers to personalize standard products.

- 😀 Job production offers flexibility and attention to detail, making it perfect for highly customized, small-scale items.

- 😀 Batch production allows for economies of scale by producing in bulk, resulting in reduced costs and consistent quality.

- 😀 Flow production is ideal for industries like bottling, where large quantities of standardized products are produced quickly and efficiently.

- 😀 Mass customization allows customers to choose from predefined options (e.g., shoe colors, initials), offering a personalized product while maintaining production efficiency.

- 😀 The automotive industry frequently uses batch production to create vehicles in groups, ensuring consistency and cost savings in the manufacturing process.

- 😀 Each production method (job, batch, flow, mass customization) plays a vital role in creating products that meet different needs, from quality to efficiency.

Q & A

What is job production and how does it work?

-Job production is the creation of unique, one-of-a-kind products tailored to specific customer requirements. Each product is made individually, such as custom wedding cakes or handmade furniture, focusing on quality over quantity.

Can you give an example of job production in action?

-An example of job production is a bakery fulfilling a custom wedding cake order. Each cake is designed and crafted based on the specific needs and preferences of the customer, making each project unique.

What are the key benefits of job production?

-Job production allows for high flexibility, personalized attention to detail, and the ability to create unique products tailored to individual customer needs.

What is batch production and how does it differ from job production?

-Batch production involves producing a set number of identical products before moving on to the next batch. Unlike job production, which focuses on uniqueness, batch production emphasizes efficiency and consistency in creating multiple units of the same product.

What industries commonly use batch production?

-Batch production is commonly used in industries like baking (e.g., making a dozen cupcakes) and automotive manufacturing (e.g., producing a set number of cars), where efficiency and economies of scale are essential.

How does flow production work?

-Flow production involves the continuous movement of products through the production process, with each stage of the process linked smoothly to the next. It’s ideal for high-volume, standardized products like bottled beverages.

Can you describe an example of flow production?

-An example of flow production is the bottling process in a plant where beverages like soda or water are filled, capped, labeled, and packaged in a continuous assembly line process.

Why is flow production efficient?

-Flow production is efficient because it allows for the rapid, continuous production of standardized goods, minimizing downtime and maximizing output in high-volume operations.

What is mass customization, and how does it combine different production methods?

-Mass customization blends the efficiency of mass production with the personalization of customization. It allows customers to personalize standard products by choosing from predefined options, such as customizing a phone case or a pair of shoes.

How does mass customization benefit both customers and manufacturers?

-Mass customization benefits customers by offering personalized products, while manufacturers can still maintain the efficiency of mass production. It’s a balance of personalization and cost-effective production.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Exploring Production Methods: Job, Batch, and Flow Production Explained | ThinkIGCSE.com

Understanding Production Volume & Plant Layout: Job, Batch, and Mass Production Explained!

What is Production? Types of Production, Factors of Production

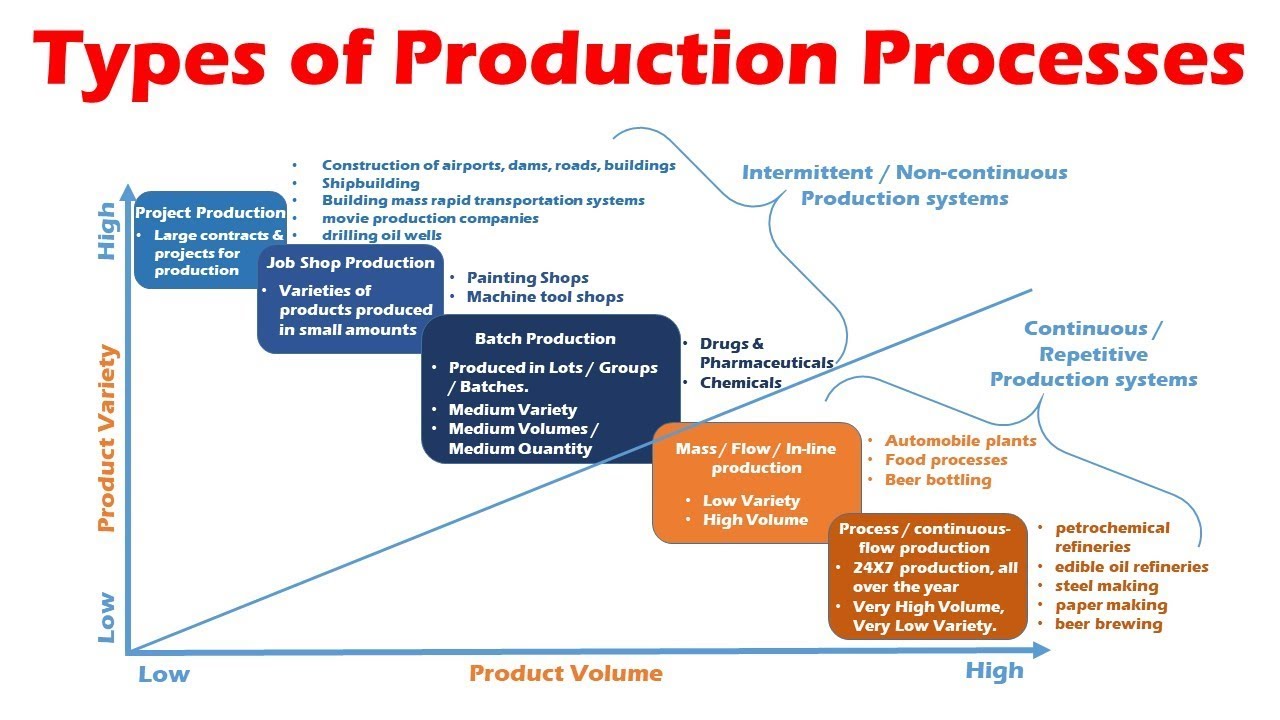

Types of Production Systems (Process, Mass, Flow, Batch, Job Shop & Project Production Systems)

Scales of Production

Materi PKK Kelas XII SMK Bab 1 Produksi Massal Part 1

5.0 / 5 (0 votes)