TLE Bread and Pastry Production BPP 7&8 - CLASSIFICATION OF FUNCTIONAL AND NON-FUNCTIONAL TOOLS

Summary

TLDRThis video script outlines an educational lesson for grade 7 and 8 students on the classification and maintenance of functional and non-functional baking tools and equipment. It covers the importance of using the right tools for the job, recognizing when tools are damaged, and maintaining them to ensure their effectiveness and safety. Students will engage in assessments and hands-on activities to identify functional and non-functional tools, perform kitchen inspections, and apply safety measures. The script also emphasizes the significance of tool care, safety, and proper usage to enhance baking efficiency and prevent accidents.

Takeaways

- 😀 Functional tools are those in good condition that can perform their intended functions efficiently.

- 😀 Non-functional tools are damaged or impaired, preventing them from carrying out their regular tasks.

- 😀 Checking the condition of tools and equipment is essential for both safety and efficiency in baking and cooking.

- 😀 Regular cleaning and maintenance of baking tools can help extend their lifespan and ensure proper functioning.

- 😀 Safety measures, such as inspecting tools for damage and using the correct tool for the job, are crucial to prevent accidents in the kitchen.

- 😀 Students will learn how to identify functional and non-functional tools through various activities and assessments.

- 😀 The condition of kitchen tools directly affects the quality of baked goods and overall productivity in the kitchen.

- 😀 Tools should be maintained according to the manufacturer's guidelines to avoid voiding warranties and ensure long-term functionality.

- 😀 Tools that are worn out or damaged, such as broken handles or cracked measuring cups, are considered non-functional and should be repaired or replaced.

- 😀 Regular tool inspection, proper storage, and the use of safety gear (aprons, hairnets) are essential to keep the kitchen safe and hygienic.

- 😀 In-depth cleaning schedules and preventive maintenance are recommended to keep kitchen equipment in good working order, reducing unnecessary downtime.

Q & A

What is the main purpose of the lesson on functional and non-functional tools?

-The main purpose of the lesson is to apply the classification of functional and non-functional tools to real-life situations, helping learners become more independent in their daily living by identifying and using tools correctly.

What are the key characteristics of functional tools?

-Functional tools are in good condition, can perform their regular functions efficiently, and are safe to use. They are properly maintained and can be used for their intended purposes without issues.

How can you identify a non-functional tool?

-Non-functional tools can be identified by impaired or damaged parts that prevent them from performing their regular functions. Methods for identification include visual inspection, functionality checks, and performance evaluation.

What is the significance of safety when using kitchen tools and equipment?

-Safety is crucial because some kitchen tools and equipment can be hazardous if not handled or stored properly. Ensuring tools are safe to use prevents accidents, protects users, and extends the longevity of the tools.

Why is it important to clean baking tools and equipment regularly?

-Regular cleaning prevents equipment failure, ensures sanitation, and extends the life of tools. Baking equipment that is not cleaned properly can accumulate flour, dough, and oils, leading to malfunction and inefficiency.

What is the role of preventive maintenance in keeping baking tools functional?

-Preventive maintenance helps identify and address minor issues before they turn into larger problems. Regular inspections and maintenance keep tools in good condition, reducing downtime and the need for costly repairs.

What should you do if you notice a worn or damaged part on your kitchen equipment?

-If you notice a worn or damaged part, it should be repaired or replaced immediately. Regular inspection during cleaning sessions can help catch these issues early and prevent further damage or malfunction.

How can improper use of tools affect the baking process?

-Improper use of tools can lead to inefficiency, failure to achieve the desired results, and potential accidents. Using the right tool for the right task ensures that the baking process is smoother, faster, and safer.

What should be done to ensure tools are stored safely and efficiently?

-Tools should be stored in their designated places to prevent damage and ensure easy access. Frequently used items should be kept in convenient, accessible locations to improve workflow and reduce clutter.

Why is it important to follow manufacturer instructions when using kitchen equipment?

-Following manufacturer instructions ensures that equipment is used safely and effectively. It also helps maintain warranty coverage and prevents damage caused by misuse, ensuring the equipment operates as intended.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

TLE Grade 7/8 Nail Care Module 4: Steps in Sanitizing Nail Care Tools and Equipment

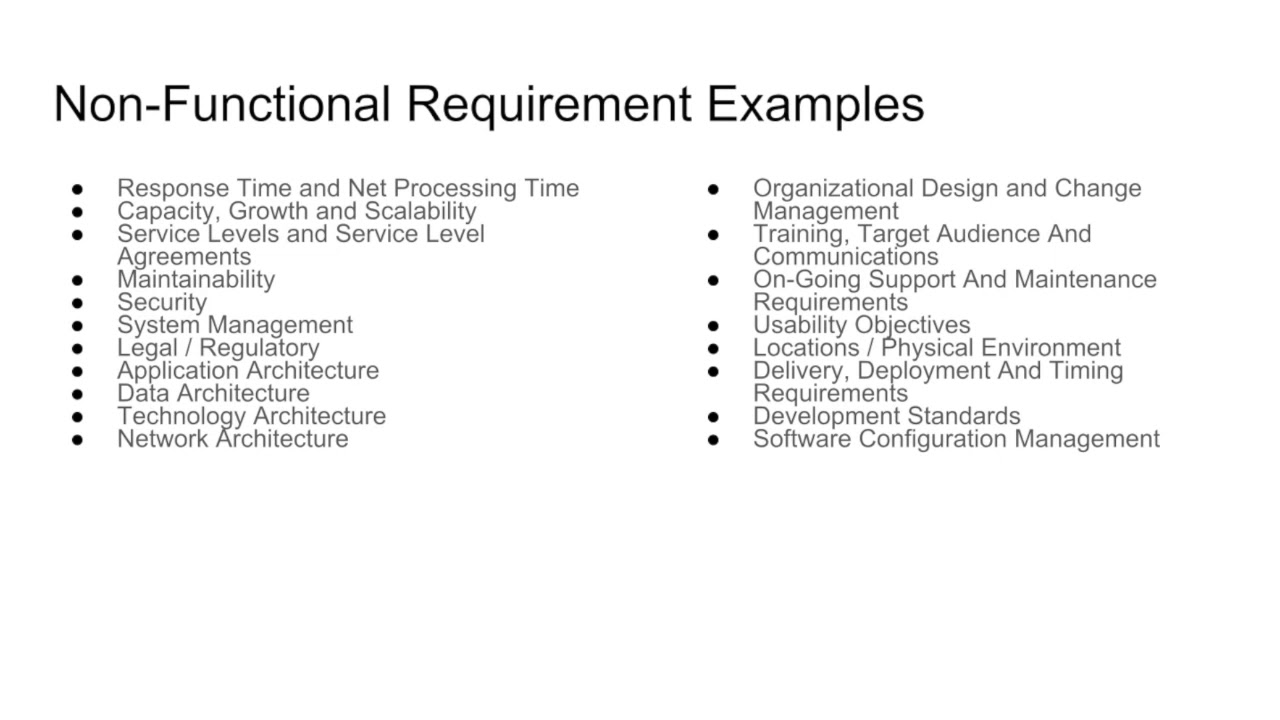

Functional and Non Functional Requirements

TLE 8:Quarter I ICT:L1 Tools anf Equipment in ICT Appopriate Sofware Applications for Specific Task

WILAYAH DAN TATA RUANG 🏡🏢 || GEOGRAFI KELAS 12 KD 3.1

Materi PJOK Kelas 7 Tenis Meja

TLE 9 Cookery-Quarter 1-Module 1: Clean, Sanitize and Store Kitchen Tools and Equipment

5.0 / 5 (0 votes)