Operations Crash Course

Summary

TLDRThe video provides an overview of key manufacturing concepts such as bottlenecks, direct and indirect labor, and the Andon system. It explains how bottlenecks in production can slow down operations and introduces the Andon system, which helps workers signal for assistance. The video distinguishes between direct labor, where workers are hands-on in production, and indirect labor, which supports these roles. Additionally, it highlights the role of a 'water spider,' a worker who delivers materials to direct labor, ensuring smooth production flow. These concepts aim to enhance efficiency and preparedness in manufacturing settings.

Takeaways

- 😀 Bottleneck in production refers to a stage in the process where the flow is slowed down due to capacity limitations, affecting overall productivity.

- 😀 An Andon system helps workers signal for assistance when faced with a production issue, such as running out of materials like cookie dough.

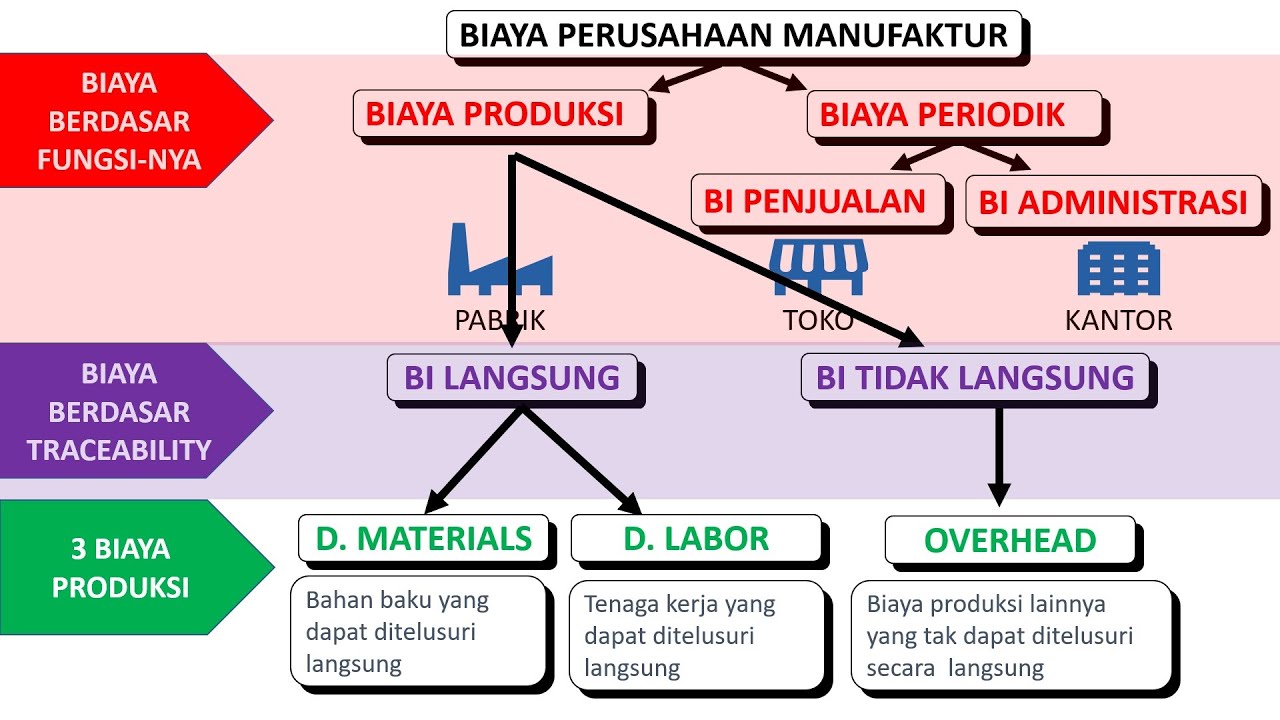

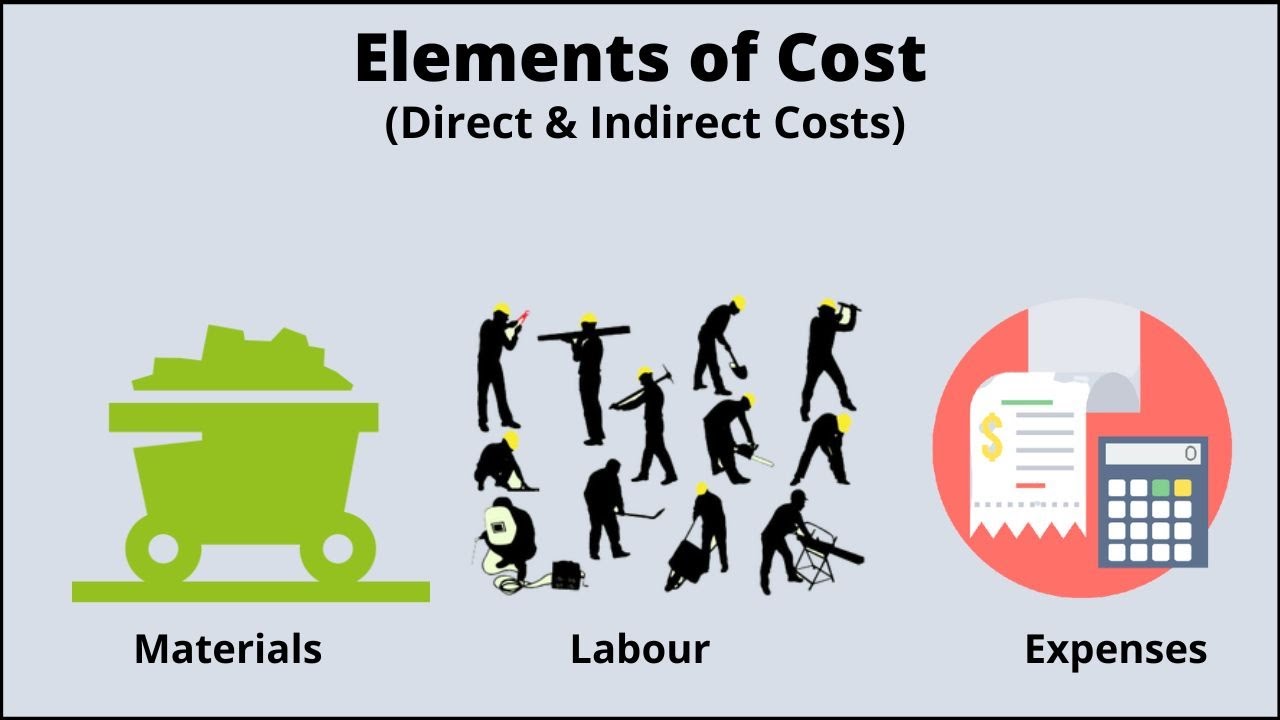

- 😀 Direct labor involves workers who are directly involved in the production process, such as assembling or packaging products.

- 😀 Indirect labor includes roles that support direct labor, like managers or administrative staff, but don’t contribute directly to the physical production.

- 😀 The Andon light system ensures quick notification of issues, reducing downtime and maintaining productivity by allowing for faster assistance from other workers.

- 😀 Direct labor costs can be traced back directly to the product being produced, while indirect labor costs are harder to associate with a specific product.

- 😀 A water spider is a role that supports direct labor by delivering necessary materials to workers on the production line to avoid delays.

- 😀 Without water spiders, workers would need to leave their stations to gather materials, leading to decreased productivity and potentially fewer units produced.

- 😀 Indirect labor roles, such as management or support staff, contribute to the efficiency of the production process, but their impact is not immediately visible in the product output.

- 😀 Understanding these roles—direct labor, indirect labor, and support systems like water spiders—helps in preparing for future roles in manufacturing or production environments.

- 😀 The video emphasizes the importance of being aware of the key processes in a production facility to prepare for any job roles, whether direct or indirect labor.

Q & A

What is a bottleneck in a production process?

-A bottleneck refers to a part of the production process that limits the overall output due to inefficiency or capacity constraints.

How does the Andon system work in a production environment?

-The Andon system allows workers to signal when they need help or run into an issue, such as running out of materials, by pressing a button that activates a light. This helps notify others immediately to provide assistance without the worker leaving their station.

What role does direct labor play in a production line?

-Direct labor involves workers who are directly engaged in the production process, such as those assembling products. The labor costs of direct workers can be traced directly back to the products being created.

What is the difference between direct labor and indirect labor?

-Direct labor refers to workers who are physically involved in creating products, while indirect labor refers to roles that support the production process but are not directly involved in it, such as management or administrative support.

What is an example of a direct labor role in the provided script?

-An example of direct labor in the script is the worker on the assembly line who scoops cookie dough into the ice cream.

Why is indirect labor considered essential despite not being directly involved in production?

-Indirect labor is essential because it supports the direct labor process, helping with management, organization, and provision of materials or assistance, thus ensuring the production process runs smoothly.

What is the function of a water spider in a production environment?

-A water spider's role is to deliver materials or supplies to workers engaged in direct labor. This ensures that the direct workers can stay focused on their tasks while the water spider handles material logistics.

How does the water spider contribute to production efficiency?

-By delivering necessary materials to direct labor workers, the water spider helps prevent delays caused by workers needing to leave their stations to fetch supplies. This keeps the production line running smoothly and efficiently.

How would the Andon system help a worker who runs out of materials?

-The Andon system would allow the worker to signal their issue by activating a light, which notifies others to assist in resolving the problem, such as bringing more materials, without the worker having to leave their station.

What could happen if the water spider was not available in the production process?

-If the water spider were not available, workers would need to leave their stations to fetch materials, which could cause delays and reduce overall production output.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

(FACIL) Materiales Directos, Mano de Obra Directa, Costos Indirectos de Fábrica

Biaya Produksi | Biaya Non Produksi | Menganalisis Biaya Prototype Produk Barang/Jasa

Konsep Dasar Akuntansi Biaya dan Akuntansi Manajerial

Menghitung Harga Pokok Produksi - Part 1

KEGIATAN EKONOMI - Bab III : Aktivitas Manusia Dalam Memenuhi Kebutuhan - Video Pembelajaran IPS

Elements of cost | Direct and Indirect: Material, Labor, & Expenses

5.0 / 5 (0 votes)