Automated Industrial Lines | Assembly Lines

Summary

TLDRThis video explains the key differences between production and assembly lines in automated manufacturing systems. While production lines focus on the manufacturing process of the work part itself, assembly lines concentrate on adding components to a base part. The video covers essential assembly line components such as part feeding mechanisms, including hoppers, feeders, selectors, orienters, feed tracks, and escapement/placement devices. Additionally, it provides insight into different part feeding systems, such as rotary indexing tables and robotic placement devices, and highlights the importance of synchronization for efficient assembly line operations.

Takeaways

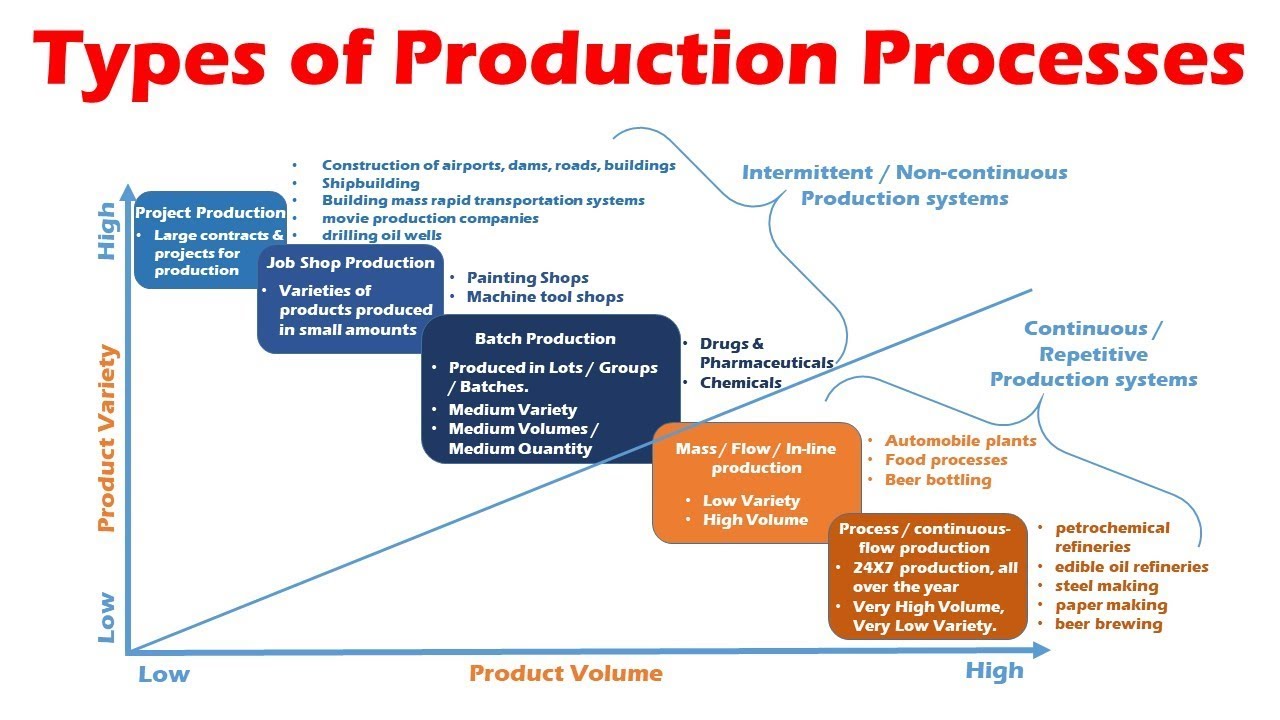

- 😀 Automated lines are used in manufacturing and can be categorized into production lines and assembly lines, with the primary distinction being that production lines perform manufacturing processes on work parts, while assembly lines focus on assembling new components onto a base part.

- 😀 The main difference between production lines and assembly lines lies in the type of tasks performed at each station, with assembly lines involving the addition of components to a base part, while production lines modify or process the base part itself.

- 😀 Assembly lines require a part feeding mechanism that delivers new components to the assembly machine for placement onto the base part, ensuring each station adds specific components as the product progresses.

- 😀 A typical assembly workstation has a supply of base parts and components from the part feeding mechanism, with each station adding one part to the base part until the final product is fully assembled.

- 😀 Part feeding mechanisms are crucial in assembly lines, and they typically consist of a hopper (for storing parts), part feeders (for orienting parts correctly), and a feed track (acting as a buffer for the assembly head).

- 😀 The hopper stores parts in a disorganized manner, and part feeders reorient the parts to ensure they are correctly positioned for assembly, often involving multiple sub-mechanisms like selectors and orienters.

- 😀 Selectors identify correctly oriented parts, while orienters adjust parts to ensure they are in the proper orientation before they are sent to the feed track.

- 😀 The feed track, either gravity-fed or powered, transports parts to the assembly head. It serves as a buffer, ensuring the timely movement of parts for assembly.

- 😀 Escapement and placement devices remove parts from the feed track and position them under the assembly head or fixture for assembly, ensuring precise synchronization of part placement.

- 😀 Automated assembly lines can involve various types of assembly processes, including welding, mechanical fastening, and adhesive joining, depending on the product being assembled.

Q & A

What is the key difference between a production line and an assembly line?

-The key difference is that on a production line, a manufacturing process is performed on the work part (e.g., machining or shaping), while on an assembly line, only the assembly of parts onto a base part occurs.

What is the role of the work transport system in an assembly line?

-The work transport system provides the base part to each workstation, ensuring that it is supplied for assembly with new components from other sources.

What is a part feeding mechanism, and why is it important in assembly lines?

-A part feeding mechanism ensures that the correct components are supplied to the assembly machine. It is crucial for providing the necessary components in the correct orientation and timing for assembly.

How does a hopper function in a part feeding mechanism?

-A hopper stores the parts to be delivered to the assembly machine. Parts are loaded haphazardly into the hopper, from which they are then retrieved and properly oriented for assembly.

What is the role of selectors and orienters in the assembly process?

-Selectors ensure that only parts in the correct orientation are passed to the next stage, while orienters adjust improperly oriented parts to the correct position before feeding them to the assembly machine.

What are feed tracks, and how do they contribute to the assembly line?

-Feed tracks act as buffers for the assembly machine, storing correctly oriented parts before they are placed onto the assembly line for further processing. They can be powered or gravity-assisted.

What is the difference between an escapement and a placement device?

-An escapement mechanism allows a part to fall into place using gravity or powered feed tracks, while a placement device picks up a part and places it precisely onto the work carrier or fixture using robotic manipulators.

What types of feed tracks are commonly used in automated assembly lines?

-The two main types of feed tracks are powered feed tracks, which move parts using a motorized system, and gravity feed tracks, where parts are moved by gravity, falling into position as needed.

What are typical parts produced on automated assembly lines?

-Automated assembly lines are used to produce a variety of parts, such as electronic components, automotive parts, packaging items, and many other consumer goods.

What assembly processes are typically used in automated assembly lines?

-Typical assembly processes include welding, mechanical fastening (e.g., screws, bolts), and adhesive bonding, with each product possibly requiring a combination of these methods.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Automated Industrial Lines | Production Lines

Types of Production Systems (Process, Mass, Flow, Batch, Job Shop & Project Production Systems)

Production Systems - Facilities & Manufacturing Support Systems

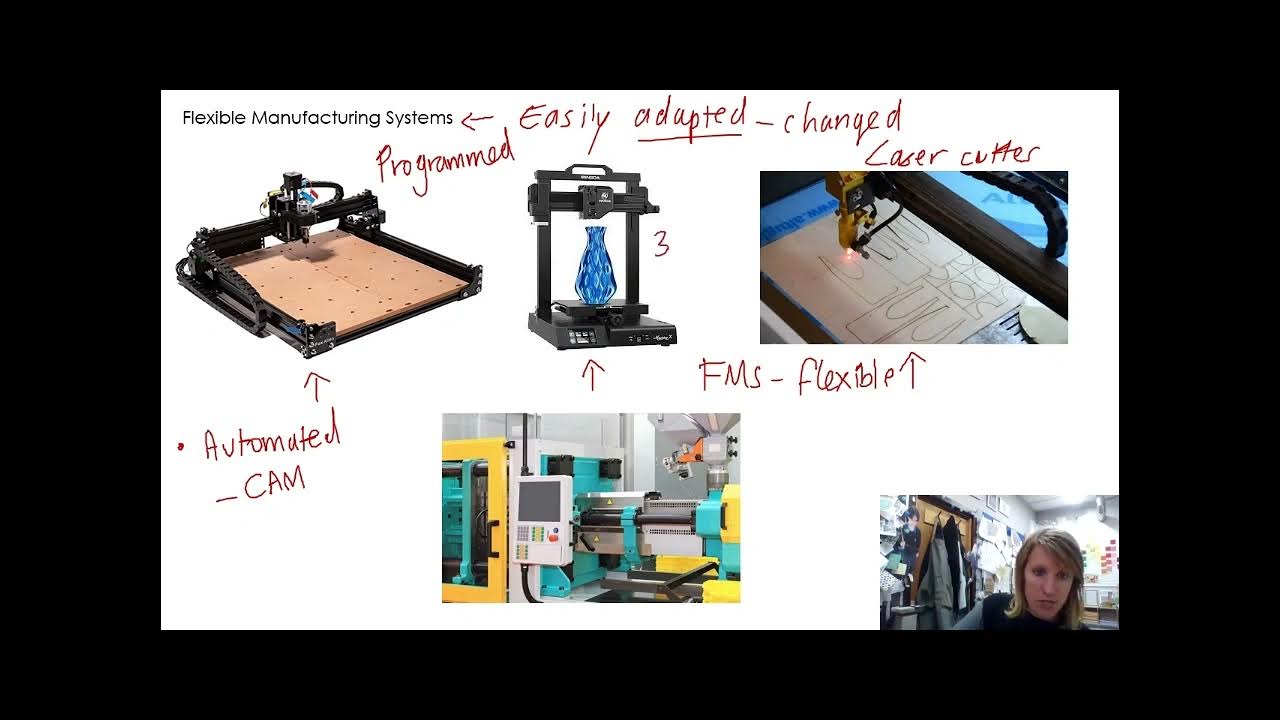

Video 2 - Flexible and Lean Manufacturing

8. VÍDEO - Processos Físicos Industriais

Artificial Intelligence and manufacturing

5.0 / 5 (0 votes)