History of the assembly line part A | What is an assembly line | Business History

Summary

TLDRIn this video, Kiron Kasbekar explores the evolution of the assembly line, a transformative method of mass production that revolutionized industries worldwide. He traces its origins from pre-industrial craftsmanship to its implementation in early shipbuilding at Venice’s Arsenal. Highlighting key developments, including Adam Smith's division of labor and innovations in machine tools, the video delves into how figures like Ransom Eli Olds and Henry Ford advanced assembly line techniques, particularly in automobile manufacturing. The story underscores how this system drastically reduced labor costs, increased efficiency, and changed manufacturing forever.

Takeaways

- 😀 The assembly line is a manufacturing process that breaks production into a series of steps, making mass production possible across industries like automobiles and engineering.

- 😀 Some industries, like chemicals and petroleum, do not use assembly lines because their processes are continuous and involve minimal human labor.

- 😀 The assembly line reduced labor costs by allowing unskilled workers to perform simple, repetitive tasks, instead of requiring specialized skills for the entire production process.

- 😀 Before the assembly line, manufacturing was more disorganized, with workers performing a variety of tasks, including fetching materials and assembling parts, often with variable results.

- 😀 Historically, products were made by skilled craftsmen using hand tools, and the process required trial and error to ensure parts fit together properly.

- 😀 Early examples of the division of labor in manufacturing can be seen in ancient China and the Venetian Arsenal, where mass production processes were used long before the Industrial Revolution.

- 😀 Adam Smith's *The Wealth of Nations* (1776) highlighted the division of labor in pin-making, where different workers performed distinct tasks, foreshadowing the assembly line model.

- 😀 Key innovations in manufacturing during the 19th century, such as automatic flour mills, conveyor belts, and machine tools, laid the foundation for modern assembly lines.

- 😀 Henry Ford is credited with perfecting the moving assembly line in 1913, using a conveyor belt to move products through the production process, reducing manufacturing time and costs.

- 😀 The Ford Motor Company's adoption of the moving assembly line allowed the Model T to be produced in just 90 minutes, revolutionizing mass production and making cars affordable for a broader market.

Q & A

What is an assembly line?

-An assembly line is a manufacturing process where production is divided into a series of steps, each completed by a different worker. It allows products to be made more efficiently by breaking down complex tasks into simpler, specialized ones.

Why don't industries like chemicals, petrochemicals, and petroleum refineries use assembly lines?

-These industries are considered process industries, where production is continuous and often involves chemical reactions. There is minimal human involvement, and the process cannot be broken down into discrete tasks as in an assembly line.

What were some of the challenges in manufacturing before the assembly line?

-Before the assembly line, products were made by hand by skilled craftsmen, and fitting parts into a product was often a trial-and-error process. This led to inconsistent product quality and a reliance on the skill level of individual workers.

How did the division of labor emerge in manufacturing?

-As workshops grew larger, owners began to recognize the benefits of dividing work among specialists. This allowed for faster and more efficient production, and workers no longer needed to be skilled in every task but specialized in one.

What is the significance of Adam Smith's description of the pin factory?

-Adam Smith's account in *The Wealth of Nations* highlighted how the division of labor could improve efficiency. In the pin factory, each worker performed a specific task, speeding up production and reducing the need for specialized knowledge across the entire process.

What role did the Portsmouth Block Mills play in the development of the assembly line?

-The Portsmouth Block Mills, established in the early 19th century, fully automated the production of pulley blocks. This represented one of the earliest industrial examples of a continuous, linear assembly process, laying the groundwork for the modern assembly line.

How did Henry Ford improve the assembly line system?

-Henry Ford introduced a moving conveyor belt system at his Highland Park plant in 1913. By moving the product to the worker, rather than the other way around, Ford dramatically reduced manufacturing time and labor costs, enabling mass production of automobiles.

What is the difference between Ransom Eli Olds' assembly line and Henry Ford's?

-Ransom Eli Olds introduced the assembly line in 1901 at the Oldsmobile factory, with the Oldsmobile Curved Dash being the first mass-produced car. However, Ford's contribution in 1913 improved upon this with the moving conveyor belt, which greatly increased the speed and efficiency of production.

How did the assembly line impact the cost and accessibility of products?

-The assembly line lowered production costs by using unskilled workers and minimizing time spent on each product. This made mass-produced goods, like cars, more affordable and accessible to the general public.

Why is the debate over who invented the assembly line (Olds vs. Ford) not central to the video's focus?

-While the debate over whether Olds or Ford was the first to implement the assembly line is interesting, the focus of the video is on how the assembly line revolutionized manufacturing. The main takeaway is the transformative impact it had on production processes and industries worldwide.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Fordism 1920s USA

The 1920s: Innovations in COMMUNICATION and TECHNOLOGY [APUSH Unit 7 Topic 7] Period 7: 1898-1945

Job, batch, flow and mass customization methods - Business Management - Teacher RK

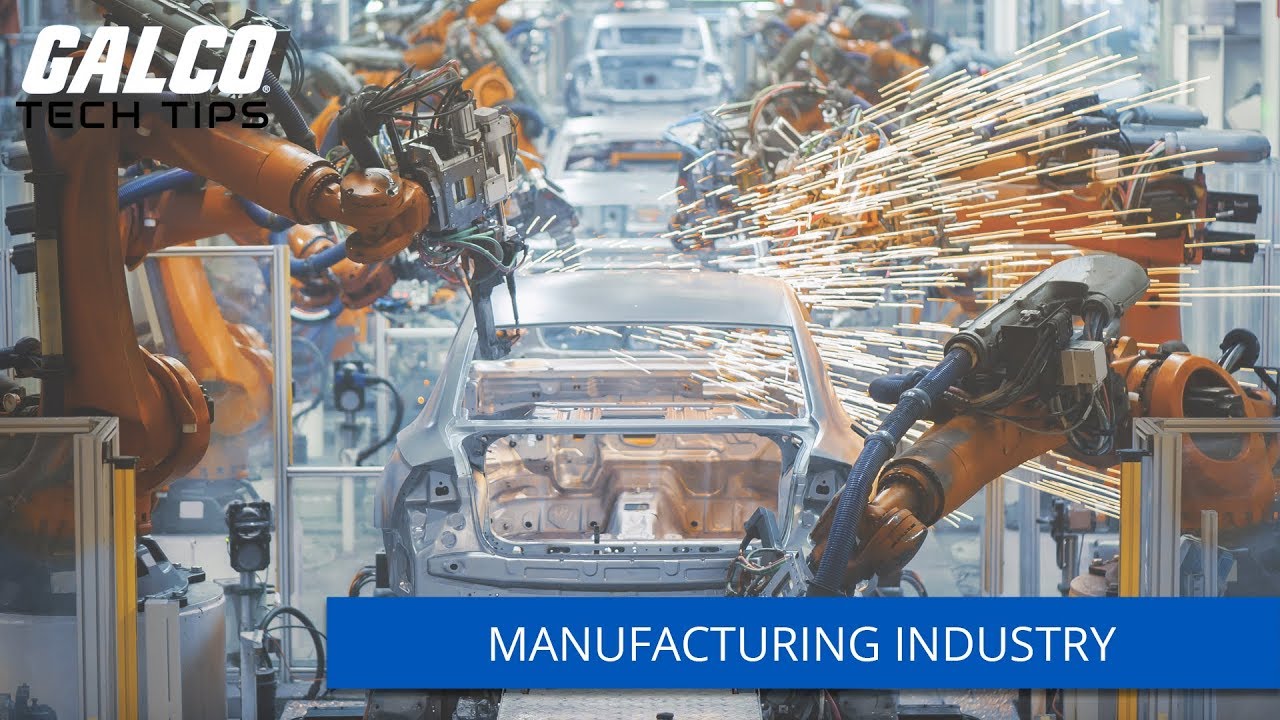

Manufacturing Industry Overview - A Galco TV Tech Tip | Galco

Estudos Organizacionais - Henry Ford e a Linha de Montagem - Fordismo

BALANCEO DE LÍNEAS (PESO POSICIONAL) | EJERCICIO RESUELTO

5.0 / 5 (0 votes)