Evaporator Controller - EKE 400 Industrial Refrigeration industrial engineering

Summary

TLDRThis video provides an in-depth look at industrial refrigeration systems, focusing on the role of controllers in managing complex components such as valves, fans, and evaporators. Sponsored by Danfoss, the video explains the basics of refrigeration circuits, including the process of defrosting and controlling refrigerant flow. It highlights the importance of controllers for optimal system performance, including the coordination of defrost cycles, valve control, and fan speed adjustments. Viewers are introduced to the EKE400 controller and its integration with various system components for efficient, safe operation. Additional resources and a detailed technical guide from Danfoss are also available.

Takeaways

- 😀 Industrial refrigeration systems are large and complex, requiring precise control of components like valves and evaporators to ensure efficiency and optimal performance.

- 😀 The EKE400 controller by Danfoss is central to managing these systems, allowing communication with and control of various components to optimize their operation.

- 😀 A basic industrial refrigeration system consists of components like the compressor, condenser, receiver, liquid separator, and evaporator, each playing a vital role in cooling.

- 😀 The evaporator is responsible for absorbing unwanted heat and cooling the air, while moisture in the air can freeze onto the heat exchanger, reducing efficiency.

- 😀 Hot gas defrost is a method used to periodically melt ice buildup on the evaporator, ensuring it remains effective. The refrigerant passes through the evaporator in reverse to accomplish this.

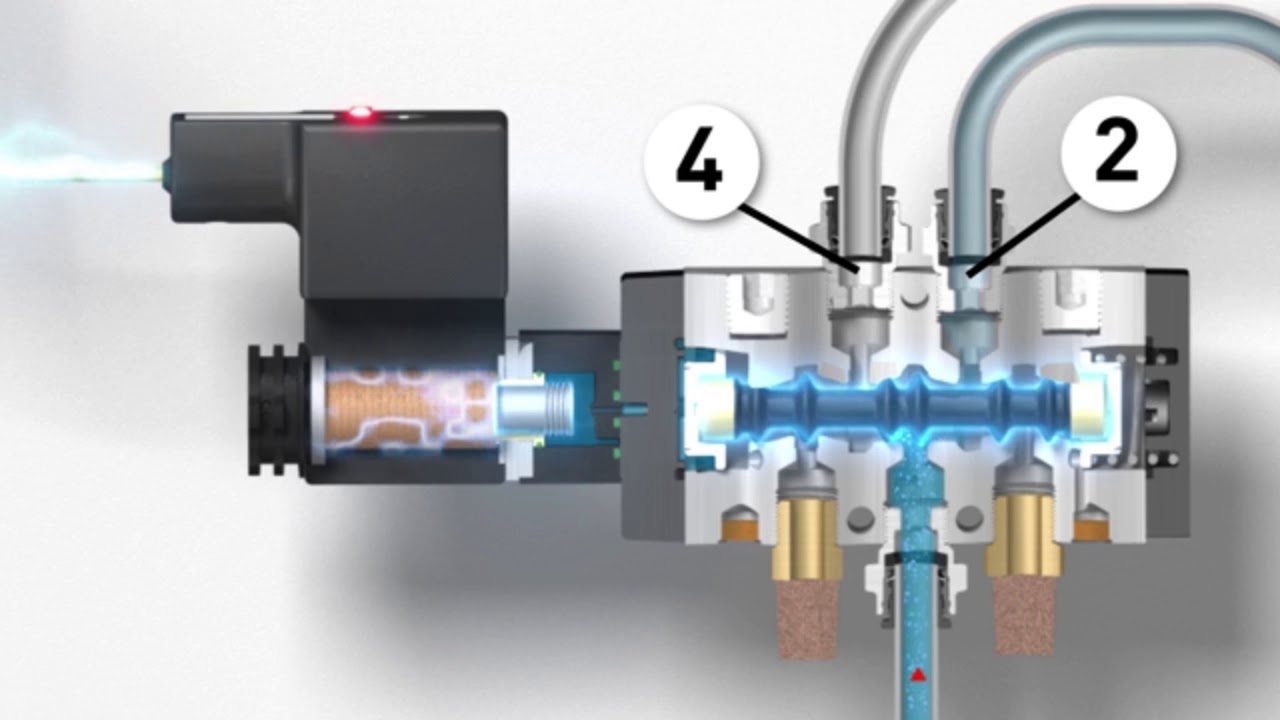

- 😀 Controllers manage solenoid valves, evaporator fans, and temperature sensors to control the system's operation during both normal and defrost cycles.

- 😀 Key sensors and components such as temperature sensors and gas detectors can be connected to the controller for better monitoring and safety.

- 😀 Multiple evaporators in a system can be synchronized using multiple controllers, allowing coordinated defrost cycles and centralized temperature monitoring.

- 😀 Setting up the controller involves specifying the type of evaporator, temperature settings, defrost types, and valve configurations to ensure optimal operation.

- 😀 The use of controllers reduces installation time and cost, increases system flexibility, and ensures safe and efficient operation through proper defrost control and feedback monitoring.

- 😀 Linking controllers to a PLC system allows remote monitoring and control, providing real-time insights into system performance and enabling remote adjustments.

Q & A

What is the main purpose of the EKE400 controller in industrial refrigeration systems?

-The EKE400 controller is used to optimize the operation of industrial refrigeration systems by controlling the solenoid valves, evaporator fans, and temperature sensors, as well as coordinating defrost cycles and ensuring efficient cooling.

How does the hot gas defrost process work in industrial refrigeration systems?

-In hot gas defrost, high-pressure vapor refrigerant from the compressor is directed through a valve station into the evaporator. This reverses the refrigerant flow, effectively turning the evaporator into a condenser to melt any ice buildup. The melted ice is collected in a drip tray to prevent it from freezing again.

What are the primary components in a single-stage industrial refrigeration system?

-The main components of a single-stage refrigeration system include the compressor, condenser, receiver, liquid separator, and evaporator. These components work together to remove heat from a room or space.

Why is defrosting necessary in an industrial refrigeration system?

-Defrosting is necessary because moisture from the air condenses and freezes on the heat exchanger surfaces of the evaporator, decreasing the system's efficiency. Periodic defrosting helps maintain optimal heat exchange by removing this ice buildup.

What is the role of the evaporator in an industrial refrigeration system?

-The evaporator absorbs unwanted heat from the ambient air by circulating refrigerant through its heat exchanger. As the refrigerant absorbs heat, it changes into a mixture of liquid and vapor, which is then pumped back into the system for further processing.

How does the EKE400 controller reduce installation costs and time?

-The EKE400 controller reduces installation costs and time by offering an integrated solution to control multiple system components, such as valves and fans. It simplifies setup with an inbuilt wizard, reducing the complexity and time required for configuration.

What are some other defrost methods that can be used apart from hot gas defrost?

-Other defrost methods include electrical defrost, water and brine defrost, and liquid drain defrost. These methods can be used based on system requirements and operational preferences.

How does the EKE400 controller enhance the flexibility of refrigeration system designs?

-The EKE400 controller enhances design flexibility by allowing users to control individual evaporators, adjust temperature settings, and select different defrost types. It also supports various units of measurement and languages, making it adaptable to different installation environments.

Can multiple EKE400 controllers be connected together? If so, why?

-Yes, multiple EKE400 controllers can be connected together to coordinate defrost cycles and synchronize the operation of multiple evaporators. This is especially useful in large systems where multiple units need to work together efficiently.

What is the function of the temperature sensor in the EKE400-controlled system?

-The temperature sensor provides feedback to the controller, allowing it to adjust the operation of the evaporator fans and solenoid valves to maintain the desired cooling temperature and optimize system efficiency.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

What is SCADA? Supervisory Control and Data Acquisition

Kisi-kisi UTS Sistem Penggerak Industri

Neumática Industrial, ¿Cómo Trabaja un Sistema Neumático?

Memelihara Peralatan Pneumatik - Teknik Mekatronika

Mengenal Simbol Pneumatik dan Benda Aslinya #waginothok

What Is Industrial Engineering? | What Do Industrial Engineers Do?

5.0 / 5 (0 votes)