Tutorial isi freon AC untuk pengguna AC

Summary

TLDRThis tutorial provides a detailed, step-by-step guide on how to properly recharge an AC system with refrigerant (freon). It covers essential tools like adjustable wrenches, manifold gauges, and amperage meters, as well as safety tips for handling refrigerant and ensuring the system operates efficiently. Key points include how to evacuate excess freon, monitor pressure and amperage, and the importance of using the correct refrigerant type. The tutorial also offers practical advice for maintaining your AC, avoiding refrigerant wastage, and troubleshooting common issues, ensuring your system runs smoothly and efficiently.

Takeaways

- 😀 Always ensure you have the necessary tools before refilling freon in an AC: wrench, screwdriver, manifold gauge, clamp meter, and the correct type of freon.

- 😀 When working on an AC, ensure the compressor is running for at least 10-20 minutes before starting the freon refilling process.

- 😀 Before adding freon, check for electrical leaks or any issues with the outdoor unit using a voltage tester (tespen).

- 😀 Make sure the AC is powered on during the process. If it’s powered off, you’ll need to use a scale to measure the freon.

- 😀 Never mix different types of freon (e.g., R32 with R40). Always check the AC’s label to confirm the correct freon type.

- 😀 The freon pressure should be checked using the manifold gauge, with R32 typically running at around 160 psi.

- 😀 When releasing excess freon, do so slowly to avoid waste and environmental impact. Using an adapter helps prevent freon loss.

- 😀 When refilling freon, monitor the amperage closely, as it will increase or decrease with the pressure. Ensure the amperage doesn’t exceed safe levels to avoid overheating the compressor.

- 😀 After refilling, ensure the system’s electrical voltage is stable and within the safe range (220V).

- 😀 If the amperage or pressure readings are too high, the compressor may overheat, leading to system failure. Ensure balance between amperage and pressure.

- 😀 Always securely close the valves after finishing the refilling process and check for leaks to prevent freon loss. Use soapy water for leak detection.

Q & A

What tools are necessary for recharging an AC unit with Freon?

-The essential tools include an adjustable wrench (8in, 10in, or 12in), a screwdriver (Phillips), a voltage tester (tespen), an L-wrench set, an adapter, a clamp meter (amperemeter), a manifold gauge set, and Freon that matches the AC model (e.g., R32 or R40).

How do you determine which type of Freon to use in an AC unit?

-You should check the AC unit's outdoor unit label for the specific Freon type, such as R32, R40, or R22, to ensure the correct gas is used.

Why must the AC unit be running when recharging it with Freon?

-The AC unit must be running because Freon is added while the compressor is active, which helps stabilize pressure and amperage. If the unit is off, the recharge process requires a scale to measure the Freon accurately.

What should you do if you detect a leak or electrical issue when testing the AC?

-If there is a leak or electrical issue (e.g., the outdoor unit is electrically live), you must first identify and fix the source of the leak or repair the electrical fault to ensure safety before proceeding with the recharge.

How do you attach the manifold gauge set to the AC for recharging?

-To attach the manifold gauge set, connect the blue hose to the Freon inlet valve, and connect the yellow hose to the Freon container. Ensure the fittings are secure and the valve is properly opened for Freon transfer.

What is the correct procedure for releasing Freon from the system?

-To release Freon, slowly open the valve on the yellow hose while monitoring the pressure gauge. It is crucial to do this slowly to avoid wasting Freon and to prevent environmental damage. Optionally, place the hose end in water to capture any gas released.

What should you monitor when adding Freon to ensure the correct amount is charged?

-You should monitor both the amperage (using the amperemeter) and the pressure (using the manifold gauge) during the recharge. Ensure the pressure is within the recommended range (for R32, typically 140-160 psi) and the amperage does not exceed normal operating levels to avoid overloading the compressor.

How do you know if the Freon levels are correct during recharging?

-The correct Freon levels can be identified when the pressure gauge stabilizes at the correct range, and the amperemeter shows a normal reading (e.g., around 1.6-1.8 amps). If either value is too high or low, you need to adjust the recharge accordingly.

What can happen if the amperage is too high during the Freon recharge?

-If the amperage is too high, it may indicate that the compressor is working too hard, leading to overheating, potential overload, and inefficient cooling. This may also cause increased electricity consumption.

Why is it important to ensure stable voltage when recharging an AC unit?

-Stable voltage is critical because voltage fluctuations can cause the amperage to rise, potentially causing compressor failure, overloading, or inefficient performance. The standard voltage for AC units in Indonesia is 220V; if the voltage drops significantly, it may impact the system's efficiency.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

AC 5. Pengisian Freon, Pengosongan, Pevakuman, Pengisian Oli Kompressor AC | Refrigrant Conditioning

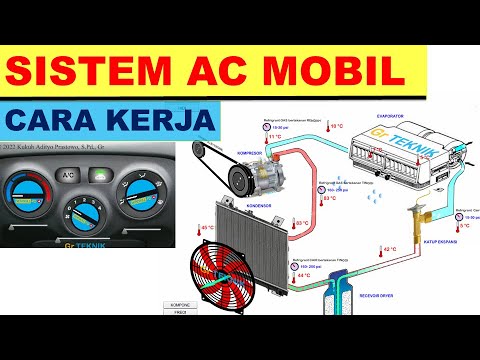

cara kerja sistem ac mobil dengan animasi siklus refrigasi freon

cara kerja sistem ac mobil

1104LST0301 AC perawatan

Praktek Sistem AC II Cara Mengganti Refrigerant (Freon) II Cara Mengisi Oli Pada Sistem AC

Switch Mode Power Supply || SMPS Practical Demo|| Explanation and working || Power Electronics

5.0 / 5 (0 votes)