Auxiliary Generator Starting Procedure from Blackout condition | Garish Jerome

Summary

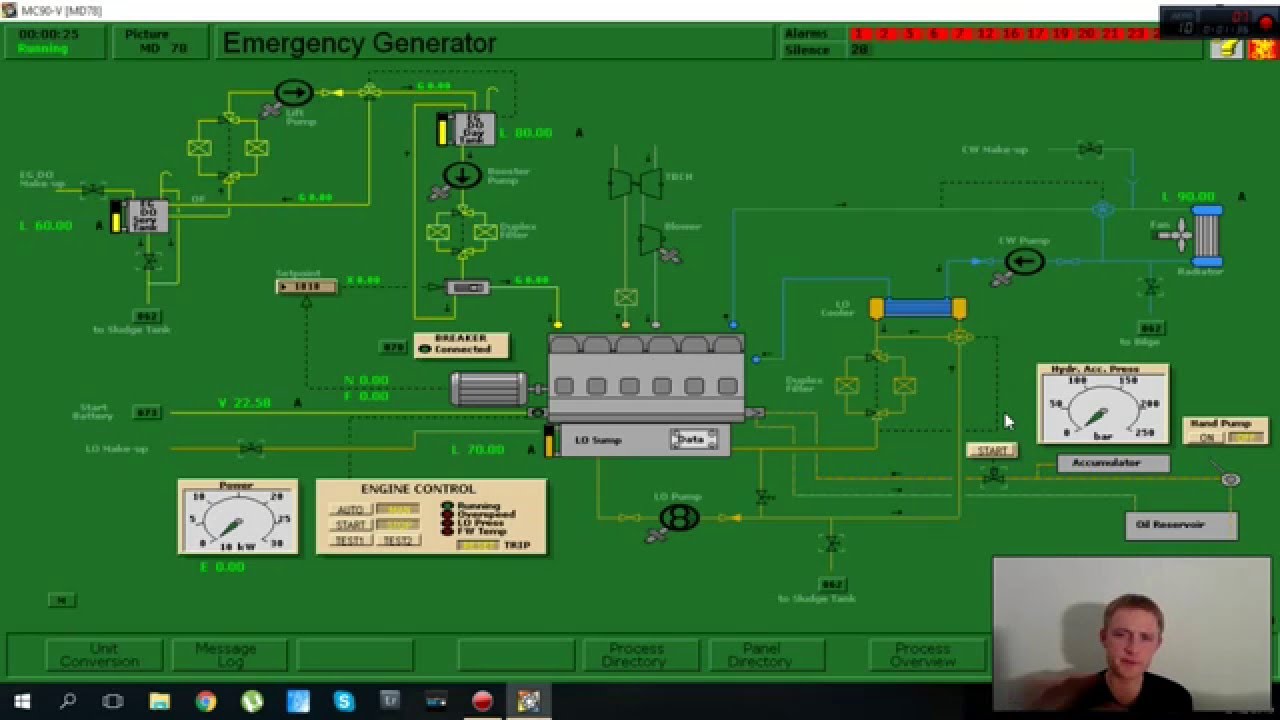

TLDRThis video guides viewers through the process of starting a main generator from a 'dead ship' condition, with step-by-step instructions for preparing both the emergency and main generators. The process includes activating air compressors, setting up the fuel and cooling systems, and ensuring proper air pressure in the system. Key actions involve managing the seawater cooling, fuel oil, and jacket water systems, followed by starting the engine and monitoring critical parameters. The video concludes with the successful transition from emergency to main generator power, preparing the ship's systems for operational use.

Takeaways

- 😀 The emergency generator is started first, and the load is applied to it (31.7 kW), allowing it to power essential systems before starting the main generator.

- 😀 Air compressors and turbochargers in the engine room require positive air supply, which is provided by starting the supply fans.

- 😀 The main generator preparation involves setting up various systems such as the air compressor, seawater cooling, and fuel oil systems before the engine start.

- 😀 The seawater cooling system for the air compressors is set up by opening the suction and delivery valves and activating the pump to ensure proper cooling.

- 😀 Fuel oil is supplied through the diesel oil system, and the fuel oil service tank is checked, with valves and filters monitored to ensure a steady supply of fuel.

- 😀 Jacket water systems for engine cooling are prepared by tracing lines from the tank to the pump, ensuring the water temperature is regulated through a three-way valve.

- 😀 The air pressure in the bottles is built up to a sufficient level (around 30 bar) to start the engine, and the air compressor ensures air bottles are filled before starting.

- 😀 The main engine is started, and key parameters such as jacket water temperature, fuel oil pressure, and turbocharger speed are closely monitored to ensure the engine runs smoothly.

- 😀 After the engine is started, the engine-driven lube oil pump takes over, making the priming pump redundant. The system stabilizes with the turbocharger gradually picking up speed.

- 😀 The generator is taken on load by switching to remote control, and the emergency bus bar is connected to the main generator, ensuring the main generator is supplying power to the system.

Q & A

What is the first step in preparing the main generator from a dead ship condition?

-The first step is to ensure the emergency generator is running, which provides power to the system, with the breakers turned on and a load of 31.7 kilowatts.

Why are the supply fans started in the engine room before starting the main generator?

-The supply fans are started to ensure positive air pressure in the engine room, as the air compressors and turbochargers will draw a large amount of air, requiring proper ventilation.

How is the main air compressor prepared for starting?

-The main air compressor is prepared by setting the priming pump to auto and monitoring the system. Once the system is primed, the air compressor is started manually, and the air bottles are filled.

What is the purpose of the seawater system in this process?

-The seawater system is used to cool the jacket water for the main air compressor. This involves opening valves for suction and delivery to ensure proper cooling of the compressor during startup.

What is the significance of using two air compressors in the process?

-The use of two air compressors ensures redundancy and reliability. While one compressor is running, the other is kept on standby in case of a failure in the active compressor.

What actions are taken to prepare the fuel oil system?

-The fuel oil system is prepared by opening the quick closing valves, ensuring fuel is delivered from the diesel oil service tank, and starting the fuel pump to supply the system.

How is the jacket water system for the engine prepared?

-The jacket water system is prepared by opening valves for the fresh water cooling system, ensuring the temperature is controlled, and starting the pump to circulate the water as needed.

What are the critical parameters to monitor after starting the generator?

-After starting the generator, it is important to monitor parameters like jacket water temperature, scavenger temperature, fuel oil temperatures, and pressures to ensure the engine is running properly.

What is the purpose of transferring the generator to the ECR and connecting to the MSB?

-The generator is transferred to the ECR (Engine Control Room) to remotely monitor and control the load. By connecting to the MSB (Main Switchboard), the generator is brought online and the load is distributed appropriately.

How is the emergency generator offloaded from the system?

-The emergency generator is offloaded by closing the tie breaker, which allows the load to be shared between the MSB and ESP. The emergency generator is then stopped and kept on standby.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级5.0 / 5 (0 votes)