Growing and Harvesting Billions Tons of Sugarcane to make Sugar - Sugar Processing Line in Factory

Summary

TLDRThis video provides an in-depth look at the refined sugar production process, from receiving raw sugar to producing high-quality, food-grade sugar. The process begins with unloading raw sugar, followed by mixing with syrup to form magma. Through a series of centrifuging, clarification, and filtration steps, impurities and color are removed. The liquor is concentrated and crystallized, and the sugar is dried and conditioned for consistent quality. The video highlights the precision and technology used in creating some of the world's best sugar products, ensuring high standards of purity and consistency throughout the process.

Takeaways

- 😀 The sugar refining process starts with receiving raw sugar from Makai mills, delivered by truck and emptied into an automated unloading hopper.

- 😀 Raw sugar is mixed with hot, concentrated syrup, forming a mixture known as magma, which is carefully controlled for density before being centrifuged.

- 😀 The centrifuge spins the magma at high speeds, separating sugar crystals from syrup and impurities, with hot water aiding in the process to remove color and other contaminants.

- 😀 The fine raw sugar crystals are dissolved in hot water to create melter liquor, which is about 65% sugar content.

- 😀 The melter liquor undergoes clarification, where lime and phosphoric acid are added, and air bubbles help remove impurities by causing them to float to the surface.

- 😀 After clarification, the liquor is passed through sand and gravel filters, followed by activated carbon columns that remove color and residual organic material, resulting in purified liquor.

- 😀 The liquor is concentrated from 65% to 78% sugar content using an energy-efficient triple-effect evaporator.

- 😀 In vacuum pans, CSR caster sugar is added to the concentrated liquor, encouraging crystal growth to produce consistent sugar crystals.

- 😀 The sugar crystals are spun in a final centrifuge to separate syrup, with adjustments made to the amount of wash water for desired crystal color.

- 😀 Excess syrup is either returned to the pans for further crystallization or used to produce different types of CSR sugar products, such as raw, caster, or coffee sugar.

- 😀 After centrifuging, the sugar crystals are dried in a rotary dryer and conditioned in a silo for 24 to 36 hours before being packaged and distributed.

Q & A

What is the first step in the refining process of sugar?

-The first step is receiving raw sugar from one of the Makai mills, which is then unloaded by truck into an automated unloading hopper, connected to a conveyor belt leading to the refinery's 1000-ton holding bin.

How is the raw sugar initially processed after unloading?

-The raw sugar is mixed with hot concentrated syrup known as raw wash. This mixture, called magma, is closely monitored for its density before being processed in a centrifuge.

What role does the centrifuge play in sugar refining?

-The centrifuge spins the magma at high speeds, exceeding 1000 revolutions per minute, separating the sugar crystals from the syrup and impurities. Hot water is also sprayed onto the magma to aid this separation.

What is the benefit of the centrifuging process?

-The centrifuging process not only separates sugar from syrup but also removes around 30% of the color from the raw sugar crystals, improving the quality of the sugar.

What happens after the raw sugar is processed into fine raw sugar crystals?

-The fine raw sugar is mixed with hot water to form melter liquor, which contains about 65% sugar content. The liquor is then passed through a coarse screen to remove large particulates.

What is phosphatation, and why is it important?

-Phosphatation is the process where lime and food-grade phosphoric acid are added to the melter liquor, followed by the introduction of air bubbles and flocculent. This helps bind impurities, which float to the surface as scum and are removed. This step is critical for removing most impurities from the liquor.

How is color removed from the liquor during the refining process?

-The clarified liquor is passed through activated carbon columns, which function like a fish tank filter. The carbon removes organic and residual material, resulting in 85% color removal.

What happens after the clarified liquor passes through the activated carbon columns?

-The fine liquor is then passed through a triple effect evaporator, which concentrates the sugar content from 65% to 78%, using an energy-efficient method.

How are the sugar crystals grown in the refining process?

-The concentrated liquor is sent to vacuum pans, where it is seeded with CSR caster sugar to promote crystal growth. This automated process ensures consistent and desired crystal sizes.

What happens to the syrup after the sugar crystals are separated?

-The syrup is returned to the pans to grow more sugar or is used to produce CSR-branded raw sugar, caster raw sugar, or coffee sugar.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

How Modern Factory Producing Crystal Sugar Efficiently?

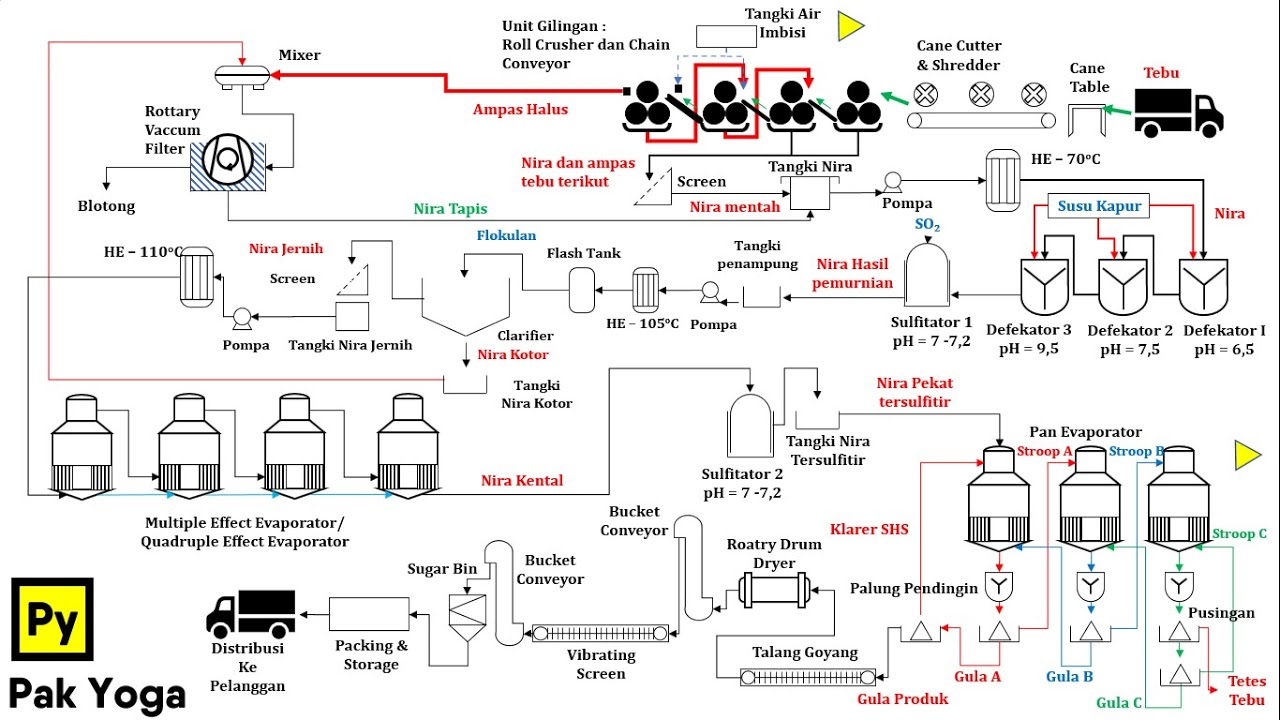

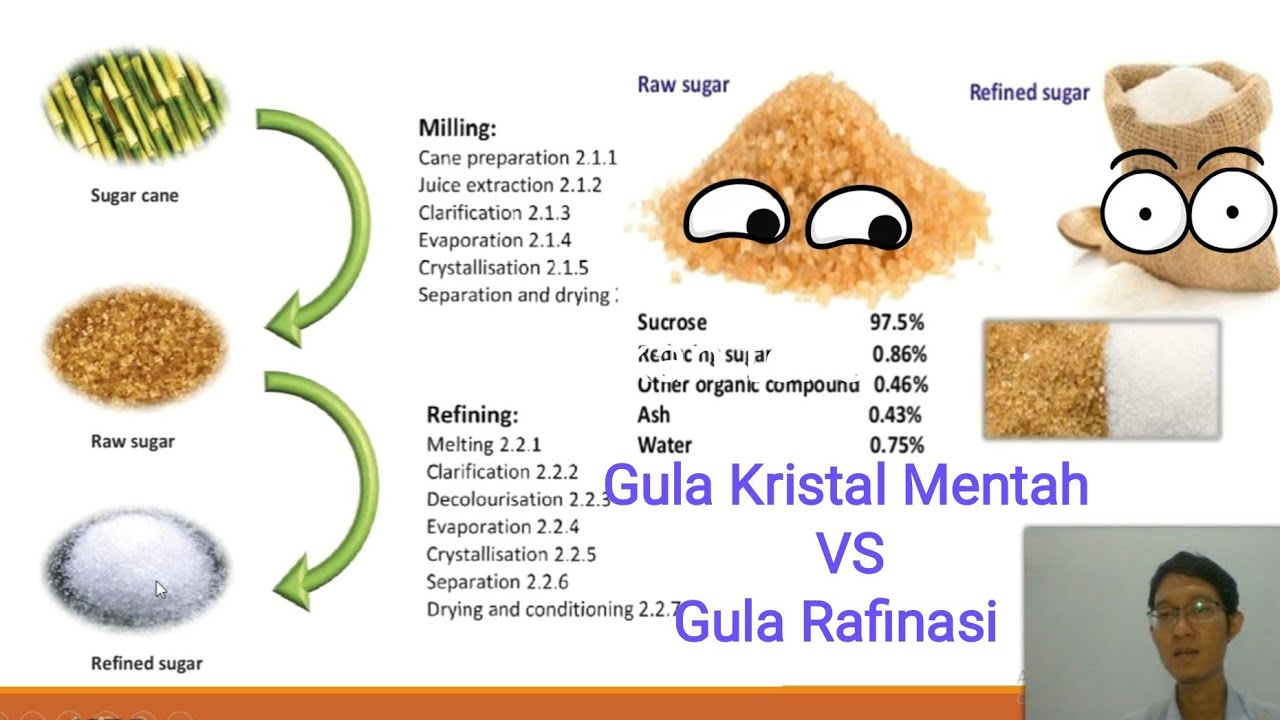

Kimia Industri - Diagram Alir Proses Pembuatan Gula tebu

Ternyata Begini Proses pengolahan tebu menjadi gula pasir Dari Awal Hingga Akhir

PENGOLAHAN LIMBAH CAIR AGROINDUSTRI GULA - METODE FISIKA BIOLOGI

Ekstraksi Tebu menjadi Nira - Diagram Alir Proses Industri Gula (part 1/4)

Membuat Gula Semut | BOCAH PETUALANG

5.0 / 5 (0 votes)