Blacksmithing - Forging a Door Knocker

Summary

TLDRIn this video, the creator demonstrates the step-by-step process of making a custom door knocker from a 5/8-inch bar and a 3/8 by 3/4-inch collar. Key techniques include welding, upsetting the bar for a solid grip, and tapering for an elegant design. The video highlights the importance of precise measurements and efficient methods, especially for creating a decorative back plate and a non-spinning ring. Concluding with thanks to supporters, the creator encourages viewers to explore their own crafting projects safely and creatively.

Takeaways

- 🔨 Start with a 5/8-inch square bar and weld a collar made from 3/8 by 3/4-inch stock to create the central knob of the door knocker.

- 📏 Measure carefully: Mark the collar length based on the material dimensions to ensure a proper fit.

- 🔥 Use a forge or torch to heat specific areas for upsetting the bar to create enough mass for welding.

- 🛠️ Employ ergonomic techniques when working with tools to minimize strain and enhance precision.

- 🌡️ Use multiple heats to refine the ball shape and ensure a smooth finish without overheating.

- 🔄 Create a notch in the form to accommodate the knob while bending the bar into a circular shape.

- 📐 The tapered twists of the bar require attention to ensure uniform twisting and avoid uneven thickness.

- ✂️ Utilize tools like plasma cutters for trimming excess material efficiently, especially for shaping the back plate.

- 🎨 Artistic design elements can be integrated into functional projects, allowing for personal expression.

- 🙌 Viewer support through platforms like Patreon enhances content creation, allowing for detailed project sharing.

Q & A

What materials are used for the door knocker?

-The door knocker is made from a 5/8-inch bar and a collar from 3/8 by 3/4-inch stock.

What is the purpose of the collar in the door knocker?

-The collar forms a large knob in the middle of the bar, which is used for knocking.

How does the blacksmith ensure the collar is the correct size?

-The blacksmith measures the collar from the center line of the bar, calculating the required material based on the dimensions of both the bar and the collar.

What techniques are mentioned for welding the collar to the bar?

-The collar is forge-welded in place using rapid hammer blows after heating.

Why is it important to manage heat during the forging process?

-Proper heat management prevents the bar from becoming too thin and ensures a good weld without overcooking the material.

What shape does the blacksmith aim to create for the back plate?

-The back plate is shaped like a long pear with scrolls at the top, which requires trimming and forging.

How does the blacksmith prevent the ring from spinning on the door knocker?

-A partition is added to keep the ring from rotating inside the keeper.

What is one challenge mentioned in achieving the twist on the bar?

-The challenge is ensuring an even twist, as thin spots twist faster than thicker areas.

What tools and methods can be used to trim the corners of the back plate?

-Trimming can be done with a chisel, hot at the anvil, or using a plasma cutter, angle grinder, or band saw.

How does the blacksmith plan to finish the door knocker for the recipient?

-The blacksmith will provide color-matched screws treated with the same wax finish as the door knocker to ensure a cohesive look.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Salmon Bay Coral Sea - Jelly Bean Pebbles

Equivalent Fractions - Review | Mathematics Grade 5 | Periwinkle

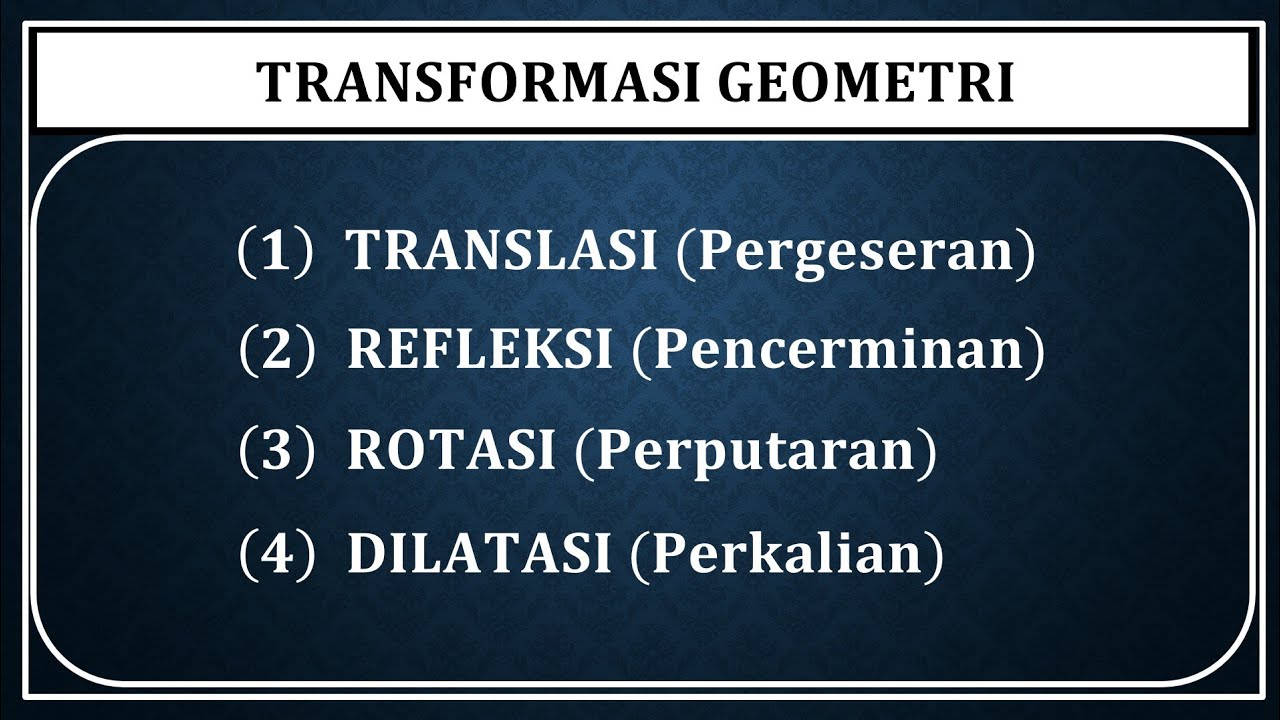

(LENGKAP) TRANSFORMASI GEOMETRI - Translasi, Refleksi, Rotasi dan Dilatasi

How To Convert Fractions to Decimals

HOW TO MAKE AN OMELETTE | perfect every time!

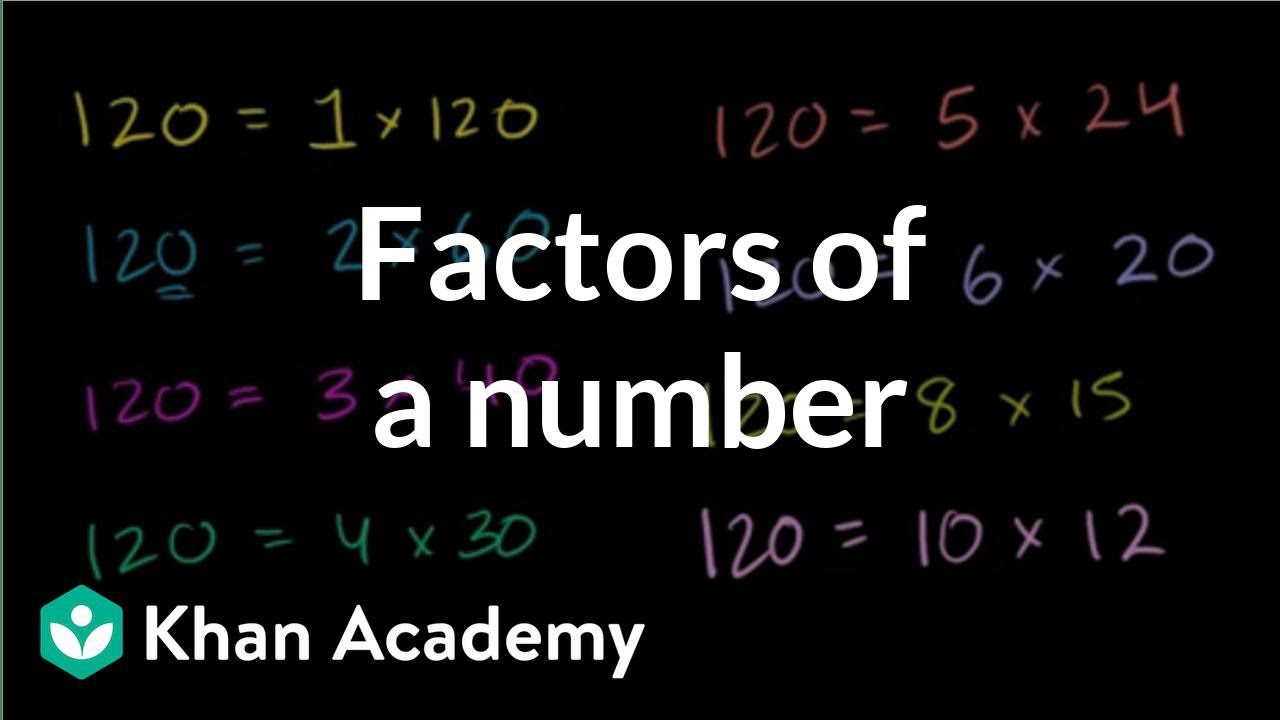

Finding factors of a number | Factors and multiples | Pre-Algebra | Khan Academy

5.0 / 5 (0 votes)