¿Cómo funciona una turbina de vapor?

Summary

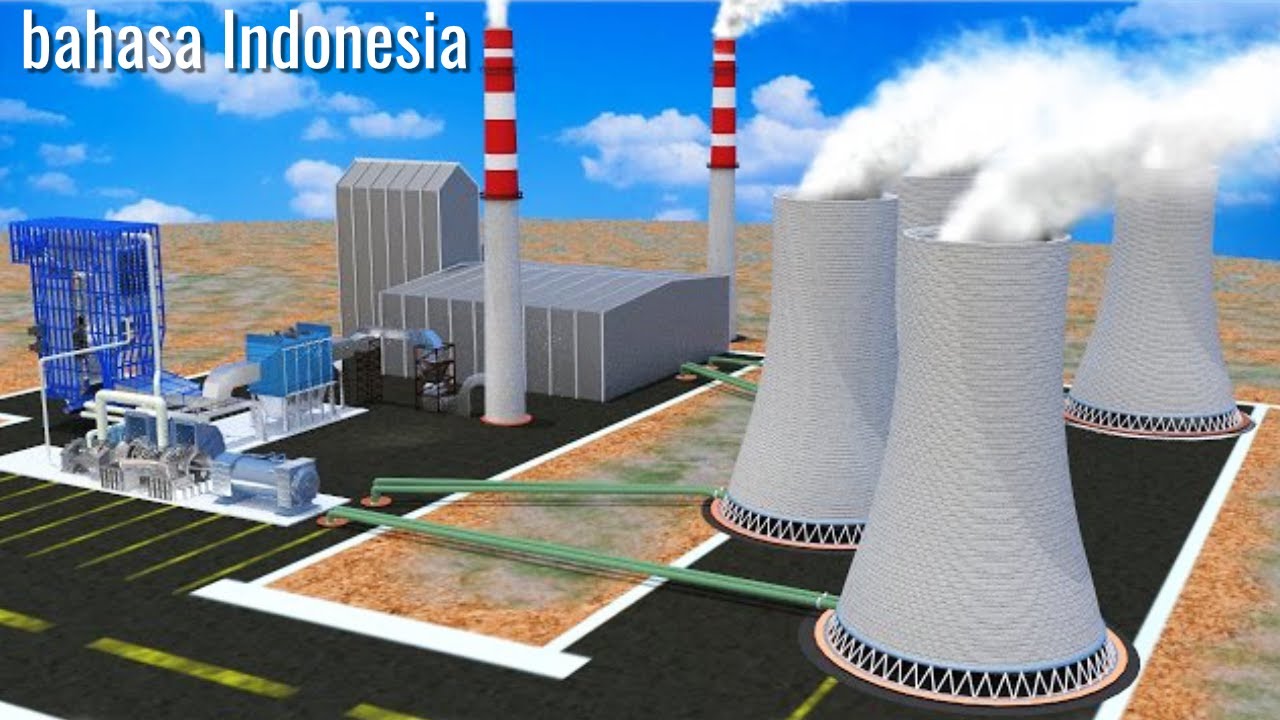

TLDRThis video explains the inner workings of steam turbines, which are vital in coal and nuclear power plants, converting thermal energy into mechanical energy. The turbine blades are aerodynamically designed to generate lift and reduce the steam's energy. The process involves managing the steam's pressure, temperature, and velocity to optimize energy transfer. With multiple stages, including high, intermediate, and low-pressure turbines, efficiency is maximized. The video also highlights the importance of regulating steam flow to maintain constant turbine speed, ensuring stable electricity generation in the plant.

Takeaways

- 😀 Coal and nuclear power plants together generate almost half of the world's energy, with steam turbines at the heart of these plants converting thermal energy into mechanical energy.

- 😀 The shape of turbine blades is aerodynamically designed to create a pressure difference, generating lift that causes the turbine to spin.

- 😀 A fluid has three forms of energy: kinetic energy, pressure, and temperature, and these decrease as the fluid passes through the turbine blades.

- 😀 The stator in a steam turbine acts as a nozzle, accelerating the fluid to increase its kinetic energy, while maintaining constant energy by reducing pressure and temperature.

- 😀 Steam turbines utilize multiple rotor stages, each designed to maintain an optimal angle for fluid flow to maximize energy transfer and efficiency.

- 😀 The reaction degree in steam turbine design is calculated using pressure and temperature energy changes relative to the total energy change in the rotor.

- 😀 To avoid high flow speeds and maintain efficiency, turbine blades are designed to increase the flow area, especially as the steam exits the turbine.

- 😀 Larger turbines use symmetric units, with steam distributed equally between them, and multiple turbine stages (high, intermediate, and low pressure) to maximize efficiency.

- 😀 The efficiency of power plants increases with higher steam temperatures, but materials limit the temperature to around 600°C.

- 😀 To boost efficiency, after the first stage of the turbine, steam is reheated in a boiler to increase its temperature and performance.

- 😀 Maintaining constant turbine speed is crucial, as the speed directly affects the frequency of electricity. Speed regulation mechanisms automatically adjust the steam flow to balance power demand.

Q & A

What is the primary function of steam turbines in power plants?

-The primary function of steam turbines in power plants is to convert thermal energy into mechanical energy. This is achieved by passing high-energy fluid (steam) over turbine blades, which creates a pressure difference and generates lift force, causing the turbine to rotate.

How does the energy in the steam change as it passes through the turbine?

-As the steam passes through the turbine, all three forms of energy—kinetic energy, pressure, and temperature—decrease. The kinetic energy is primarily used to drive the mechanical rotation of the turbine.

What is the role of the stator in a steam turbine?

-The stator is a stationary component that acts as a nozzle. It narrows the flow area of the steam, which increases the velocity of the fluid. This process helps in efficiently transferring energy to the rotor.

What is the 'degree of reaction' in steam turbine design?

-The 'degree of reaction' is a design factor that represents the ratio of energy derived from the change in pressure and temperature to the total energy in the rotor. This influences the overall efficiency and design of the turbine.

Why are the turbine blades designed to be longer towards the outlet?

-The turbine blades are designed to be longer towards the outlet to accommodate the increasing flow area. This helps in controlling the flow velocity and ensures the turbine operates efficiently without excessive speed.

What are the different stages of a large steam turbine?

-Large steam turbines are typically divided into three stages: high-pressure, intermediate-pressure, and low-pressure turbines. These stages allow for the efficient use of steam at varying pressures and temperatures.

How does reheating steam improve the efficiency of a steam turbine?

-Reheating the steam after the first stage increases its temperature, which leads to a higher efficiency in subsequent turbine stages. The higher temperature improves the energy conversion process.

What mechanism ensures the constant speed of the steam turbine?

-The speed of the steam turbine is regulated by a mechanism that adjusts the steam flow. If the turbine spins too fast, the steam flow is reduced; if it spins too slowly, the flow is increased. This ensures stable power generation and synchronization with the electrical grid.

Why is maintaining a constant turbine speed important in power plants?

-Maintaining a constant turbine speed is crucial because the frequency of the electricity produced is directly proportional to the turbine's speed. Variations in turbine speed can lead to fluctuations in the power output and disrupt the electrical grid.

How does the design of the turbine blades impact the efficiency of the steam turbine?

-The design of the turbine blades, including their length, angle, and material, plays a significant role in efficiency. Longer blades towards the outlet and optimal angles of attack help ensure maximum energy conversion from the steam, reducing energy losses and improving the overall turbine performance.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

How does a Steam Turbine Work?

Sources of Electricity | Where does Electricity come from? | Letstute

Come funziona una Centrale Termoelettrica? Ciclo di Rankine e Secondo Principio della Termodinamica

Bagaimana cara kerja pembangkit listrik tenaga termal/uap?

How does a Thermal power plant work?

OscardaFisicaIITermoLata - Experimento de Termodinâmica da latinha

5.0 / 5 (0 votes)