Materi kuliah Pengantar Bisnis, Pertemuan Ke-5

Summary

TLDRThis lecture on Introduction to Business discusses the essentials of production management, emphasizing its importance in business operations. Key topics include the differences between manufacturing and operations, a brief history of manufacturing, production process organization, factory location and layout planning, material management, purchasing, inventory control, and production scheduling. The lecture highlights how effective production management can add value to a company, while poor decisions can increase costs and reduce competitiveness. The discussion also covers modern techniques like MRP (Material Requirements Planning) and Just-in-Time inventory management.

Takeaways

- 😀 The session is an introduction to business and production management, emphasizing the importance of managing production in a company.

- 🏭 Production and operations are critical business functions that must work in harmony with other areas like marketing and finance to add value or avoid becoming a burden to the company.

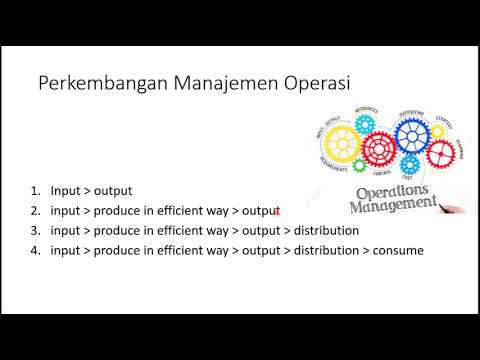

- 🤖 Manufacturing is a physical process of producing goods, whereas operations cover a broader range of activities including procurement, material management, and quality control.

- 📜 A brief history of manufacturing highlights the shift from manual work to mechanized processes in the 19th century, which allowed for mass production and standardization.

- 📊 A good production manager oversees product planning, factory layout, and inventory control, coordinating with other departments to ensure smooth production.

- 🛠️ There are three types of production layout: process layout, product layout, and fixed position layout, each suitable for different production scenarios.

- 🚚 Choosing the right factory location involves factors like access to raw materials, proximity to markets, labor availability, and transportation facilities.

- 📦 Effective inventory management aims to minimize ordering and storage costs while maintaining sufficient supply for production needs.

- 💼 Material Requirements Planning (MRP) and Just-In-Time (JIT) are systems that help manage material flow and reduce inventory costs by delivering materials precisely when needed.

- 📈 Production control ensures that production processes follow planned workflows and schedules, optimizing efficiency and preventing disruptions.

Q & A

What is the importance of understanding production management in a business?

-Understanding production management is crucial because it is one of the key functions in a business. It ensures that goods or services produced meet consumer demands and are delivered efficiently. Effective production management can add value to the company by minimizing costs and enhancing competitiveness.

How does production differ from manufacturing and operations?

-Production refers to the entire process of creating goods or services, which includes planning, designing, and executing. Manufacturing, on the other hand, is the physical process of producing tangible goods and is part of the production process. Operations involve all activities required to keep a company running, including purchasing, material management, and quality control.

Why is the selection of a factory location so important?

-Selecting the right factory location is critical because it affects operating costs, product pricing, and the company’s competitiveness. A poorly chosen location can result in higher operating costs, making it harder for the company to compete in the market.

What are the key factors to consider when choosing a factory location?

-Key factors include the availability of raw materials, proximity to the target market, access to electricity and water, availability of labor, and transportation facilities. Additionally, legal regulations, climate, and local community attitudes may also be considered.

What is mass production and what are its key advantages?

-Mass production is the process of producing goods in large quantities, often using machines. Key advantages include mechanization, which replaces human labor with machines; standardization, where interchangeable parts simplify repairs; and specialization, which divides the production process into smaller tasks for efficiency.

What responsibilities does a production or operations manager have?

-A production or operations manager is responsible for overseeing the production process to ensure that it aligns with the company’s goals. This includes planning products, selecting factory locations, controlling inventory, managing materials, controlling production quality, and managing the plant.

What is the Just-In-Time (JIT) inventory system?

-The Just-In-Time (JIT) system, developed by Toyota, is a method of inventory management where materials are delivered exactly when they are needed in the production process. This minimizes the need for large inventories, reducing storage costs and waste.

How is the process of organizing production divided between traditional and cellular systems?

-In traditional systems, the production process is often hierarchical, with each department focusing on its specific tasks. In cellular systems, teams (or cells) work together to produce a product or part of a product, giving them more responsibility for quality and quantity.

What are the three types of factory layouts and how do they differ?

-The three types of factory layouts are: 1. **Process layout**, where similar tasks are grouped together, and products move between stations as needed. 2. **Product layout**, where stations are arranged in a line, and the product moves sequentially through them. 3. **Fixed-position layout**, where the product remains in one place, and workers and machinery come to it, often used for large products like ships or airplanes.

What is Economic Order Quantity (EOQ) and why is it important in inventory management?

-EOQ is the point at which the cost of ordering inventory is equal to the cost of storing it. It is important because it helps businesses minimize both ordering and holding costs while ensuring that there is enough inventory to meet demand.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Sistem Informasi Manajemen - Video Pembelajaran Modul 1

5.1 INTRODUCTION TO OPERATIONS MANAGEMENT / IB BUSINESS MANAGEMENT / production, sustainability

operations manajemen 1

#7 Sistem Informasi Akutansi & Keuangan - Pertemuan 7 | Sistem Pemrosesan Transaksi SIA

Sistem Informasi Bisnis (E-Business) | Anshar Akil

2 1 Fungsi Bisnis dan Proses Bisnis

5.0 / 5 (0 votes)