Introducing the Cat® Automated Energy Transfer System

Summary

TLDRThe Automated Transfer System (ATS) is a robotic charging solution that enhances safety and efficiency. It includes a robot room with a robot and sliders, and a dispenser system. The control room manages operations and cleaning services. The ATS scans the area for safety, uses visual indicators, locates the receptacle box, and performs pressure washing, dust cleaning, and connector insertion. It minimizes environmental exposure during charging, indicated by a green light. Once completed, the robot retracts, closes the door, and returns to the container, allowing the truck to leave, concluding the cycle.

Takeaways

- 🤖 **Automated Charging System**: The ATS system is an automated energy transfer system that uses robotics to enhance the charging process.

- 🔄 **Productivity and Safety**: The ATS system aims to increase productivity, minimize charging downtime, and enhance safety.

- 📈 **Reliability**: The system is designed to improve the reliability of the charging process.

- 🏗️ **System Components**: The ATS consists of a robot room with a robot and sliders, a dispenser system, and a control room with supporting systems like a pressure washer and air compressor.

- 🚚 **Truck Integration**: The truck pulls up to a designated parking location where the ATS system initiates the charging process.

- 👀 **Safety Scan**: The system scans the area for safety before the robot moves into the operational zone.

- 💡 **Visual Indicators**: Visual indicators, such as blue lights, show the state of the process, indicating an autonomous operation.

- 🔍 **Receptacle Location**: The robot uses a vision system to locate the receptacle box and initiates the pressure washing cycle.

- 🔧 **Secondary Vision System**: A secondary vision system is used to locate and engage the door, and to perform a final vision check for the receptacle connector.

- 🌐 **Configurability**: The system is configurable to adapt to the seasonality of the site and specific requirements.

- 🔋 **Charging Cycle**: The system engages in a dust cleaning cycle, removes the dust cap, opens the protective cap, and inserts the connector into the receptacle box.

- 🟢 **Charging Indicator**: A green light flashes to indicate the charging cycle is in progress.

- 🔙 **Reverse Process**: After charging, the robot reverses the process by closing the protective cap, inserting the dust cap, and closing the door.

- 🏁 **Completion**: The robot returns to the ATS container, and the truck is allowed to move away once the cycle is complete.

Q & A

What is the primary function of the ATS system?

-The ATS system is designed to automate the energy transfer process, enhancing productivity, safety, and reliability in the charging process.

What components make up the ATS system?

-The ATS system consists of a robot room with a robot and sliders, a dispenser system, and a control room that includes controls and supporting systems like a pressure washer and an air compressor.

How does the ATS system ensure safety during operation?

-The ATS system uses visual indicators and a scanning process to ensure the area is clear before the robot moves into the operational zone, enhancing safety.

What is the significance of the blue light mentioned in the script?

-The blue light indicates that the ATS system is in autonomous mode, signifying that the charging process is underway.

What is the purpose of the pressure washing cycle in the ATS system?

-The pressure washing cycle is used to clean the area before the charging process begins, ensuring cleanliness and minimizing environmental contamination.

How does the ATS system locate the receptacle connector?

-The ATS system uses a secondary vision system to locate the door, engage it, and open it, followed by a final vision check to locate the receptacle connector for insertion.

What is the purpose of the dust cleaning cycle in the ATS system?

-The dust cleaning cycle is employed to remove dust and contaminants from the connector and receptacle to minimize exposure to environmental contamination during the charging cycle.

What does the green light flashing indicate in the ATS system?

-The green light flashing indicates that the charging cycle is in progress.

How does the ATS system handle the end of the charging cycle?

-At the end of the charging cycle, the ATS system reverses the process: the dust cap is reinserted, the protective cap is closed, the door is shut, and the robot returns to the ATS container.

What is the final step before allowing the truck to move away?

-The final step before allowing the truck to move away is ensuring that the robot has returned to the ATS container, signaling the completion of the cycle.

How does the ATS system adapt to different seasons or site-specific conditions?

-The ATS system is fully configurable to accommodate seasonality and specific conditions of the site, allowing for adaptability in its operations.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

kupas tuntas keunggulan tambak udang milenial

Peternakan Sapi Modern Menggunakan Teknologi Artificial intelligence. Gantikan Kerja Peternak?

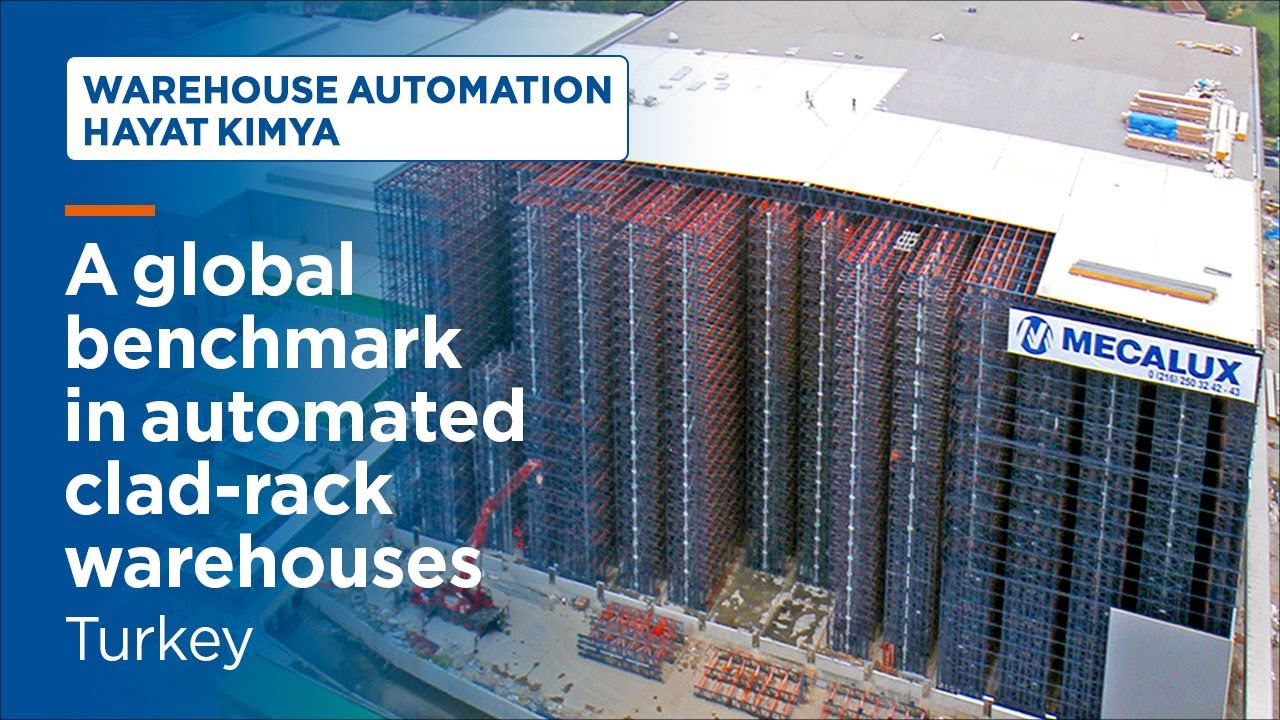

Hayat Kimya, a global benchmark in automated clad-rack warehouses

U-Heart: A new concept of Fault-tolerant isolated DC-DC converter

INCREDIBLE Fruit Harvesting Machines

Presentation: Watney Robotics

5.0 / 5 (0 votes)