MOMENT LANGKA!!! LIHAT LANGSUNG PRODUKSI TOYOTA YARIS CROSS DI PABRIKNYA!!! WAJIB TONTON! | GridOto

Summary

TLDRJoin the host as they explore the production process of Toyota Yaris Cross at PT Toyota Motor Manufacturing Indonesia in Karawang, West Java. The video offers an in-depth look from the initial pressing of metal sheets to the final assembly, highlighting safety protocols, the efficient 99-second welding of a car body, and the meticulous quality control. It also showcases the assembly of hybrid batteries, the clean room powered by renewable energy, and the final touches before the vehicles undergo a rigorous inspection. Experience the impressive manufacturing efficiency where a new car is completed every 1.65 minutes.

Takeaways

- 🏭 The video provides a tour of PT Toyota Motor Manufacturing Indonesia in Karawang, West Java, showcasing the production process of the Toyota Yaris Cross.

- 🔍 Safety is emphasized at the beginning with the presenter wearing a helmet and HIV, highlighting the importance of safety gear when entering the factory.

- 🚗 The production process is divided into different plans, with Plan 2 focusing on the Yaris Cross Veloz and Yaris models, while Plan 1 is for Fortuner and Zenix models.

- 🔩 The press shop is where the car's body parts are made from steel sheets, with 55 components for the Yaris body being produced.

- 🧹 Cleanliness is crucial in the production process, especially in areas where parts are printed, to avoid defects caused by even micron-sized dust particles.

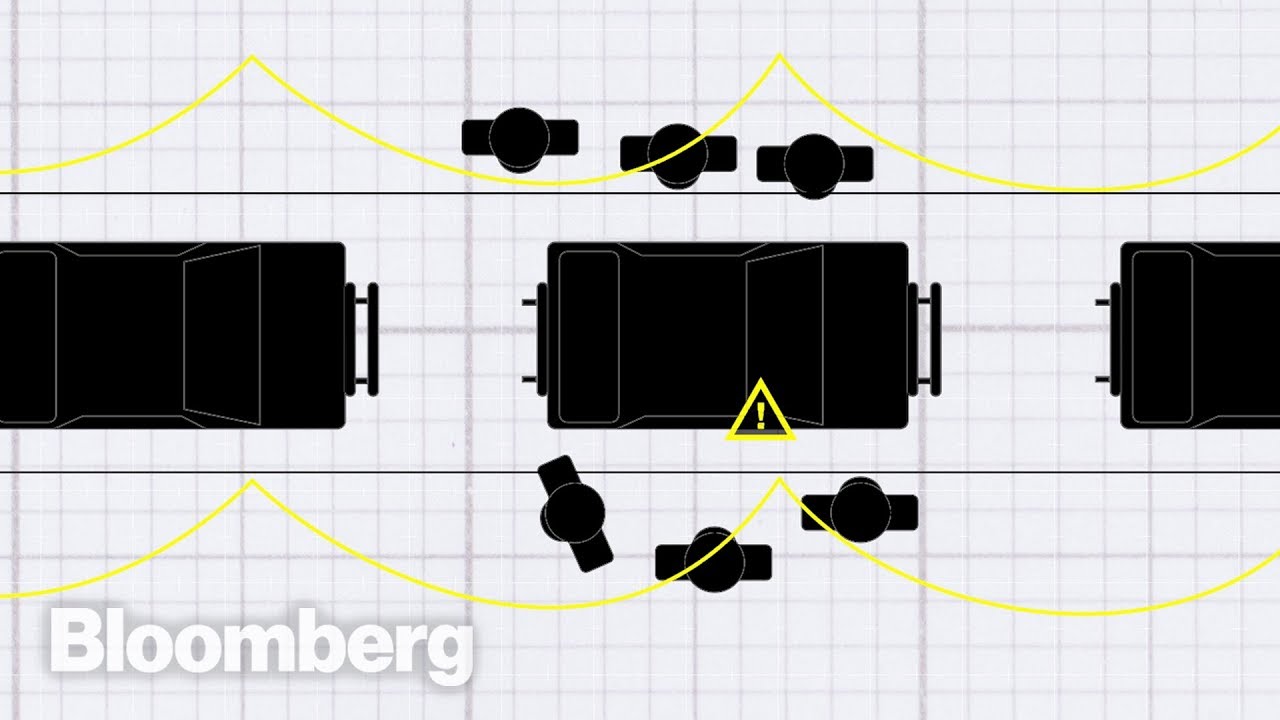

- 🤖 The welding shop is highly automated with robots, but safety remains a priority due to the sparks and flames involved in the welding process.

- ⏱️ The production line is highly efficient, with a car body completed every 99 seconds, showcasing the speed of the Toyota manufacturing process.

- 🔋 A special clean room is dedicated to the assembly of batteries for hybrid vehicles, such as the Yaris Cross Hybrid and Toyota Innova, powered by renewable energy from solar panels.

- 🔧 The assembly shop is where the car's chassis, body, and engine are combined, along with the installation of various electrical components and interior parts.

- 🛠️ The final stages of production include the installation of wheels, bumpers, and other finishing touches before the car undergoes a quality inspection, including a shower test to check for leaks.

Q & A

What is the main focus of the video?

-The main focus of the video is to provide a tour of PT Toyota Motor Manufacturing Indonesia in Karawang, West Java, showcasing the production process of Toyota Yaris Cross from start to finish.

Why does the presenter wear a helmet and safety gear?

-The presenter wears a helmet and safety gear because safety is prioritized, and it is a requirement to wear full personal protective equipment (PPE) when entering the factory.

What does 'Plan 2' refer to in the context of the Toyota factory?

-'Plan 2' refers to the production area where the Toyota Yaris Cross Veloz and Yaris models are manufactured.

What is the purpose of the press shop in the production process?

-The press shop is where the sheet metal is stamped into various body parts for the vehicles, such as side panels and other components.

How often does a part come out of the machine in the press shop?

-A part comes out of the machine every 3.75 seconds.

What is the significance of the 'sample master' in the quality control process?

-The 'sample master' serves as a reference to ensure that the parts produced by the machines match the quality standards and specifications.

What is the welding shop's role in the assembly of a Toyota Yaris Cross?

-The welding shop is where the various components from the press shop are assembled and welded together to form a complete vehicle body.

How long does it take for a car to be assembled in the welding shop?

-It takes 99 seconds, or 1.6 minutes, for a car to be assembled in the welding shop.

What is the purpose of the clean room in the battery assembly area?

-The clean room is where Toyota assembles batteries for hybrid vehicles, such as the Yaris Cross Hybrid and Toyota Innova. It is kept clean to ensure the quality and safety of the battery components.

How is the clean room for battery assembly powered?

-The clean room is powered by renewable energy from solar panels.

What is the difference between the batteries used in Yaris Cross and Innova Zenix Hybrid?

-The Yaris Cross uses a more compact lithium-ion battery with a voltage of 175.2 volts and a weight of 20 kg, while the Innova Zenix Hybrid uses a larger nickel-based battery with a voltage of up to 201.6 volts and a weight of 40 kg.

What is the final step in the assembly process before the car is ready for inspection?

-The final step in the assembly process is the installation of the bumper and filling the car with Pertamax Turbo fuel before it undergoes quality inspection.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Toyota Production Documentary Toyota Manufacturing Production and Assembly at Toyota Factory

【改良版ヤリスクロス】調べたらこんなに変わってた!25の変更ポイント一挙公開。良くなった点もあるが悪くなった点もあり【Toyota Yaris Cross】

Andon&Loom

Giảm giá sâu LÊN ĐẾN 50 TRIỆU: Báo giá tổng hợp xe Hiền Toyota trước thềm 2024 - Rước xe vi vu Tết

How Toyota Changed The Way We Make Things

Toyota Rumo ao Topo 1-6

5.0 / 5 (0 votes)