CMYK SCREEN PRINTING FOR BEGINNERS!

Summary

TLDRThis educational video offers a beginner's guide to CMYK screen printing, breaking the process into five simple steps. The host explains the basics of CMYK, uses CorelDraw for artwork preparation, and emphasizes the importance of using the right inks and screen settings. The video demonstrates the printing process, starting with the lightest color to avoid ink contamination, and concludes with tips on achieving quality prints and the limitations of the technique on light garments. The host invites viewers to share their favorite soccer player for a chance to win a shirt.

Takeaways

- 🎨 CMYK stands for Cyan, Magenta, Yellow, and Black, which are the four colors used in screen printing to create full-color images.

- 🛠️ The video provides a step-by-step guide for beginners to understand the basics of CMYK screen printing.

- 💡 Learning CMYK printing can expand business opportunities and offer more options to customers.

- 🖌️ The software used in the video for artwork preparation is CorelDRAW, which is used to convert images into halftones with specific settings.

- 🔆 It's recommended to make the image lighter than the actual color before printing, as the colors tend to darken during the process.

- 🖥️ The video mentions the importance of using the correct transparency film and color settings for separating colors in the design.

- 🔥 The screen burning process involves adjustments in mesh count and temperature settings for optimal results.

- 🎨 Processed inks are recommended for CMYK printing due to their softness, compatibility, and concentration.

- 🔄 The order of printing is crucial, starting from the lightest color (yellow) to the darkest (black) to prevent ink contamination.

- 📈 High-resolution designs are essential for better print quality, as pixelation can affect the final outcome.

- 👕 CMYK printing is primarily suitable for light garments, with additional considerations needed for dark garments.

Q & A

What is the main topic of the video?

-The main topic of the video is CMYK (Cyan, Magenta, Yellow, and Black) printing for beginners, focusing on screen printing full-color images.

Why is it important to learn CMYK printing according to the video?

-Learning CMYK printing is important as it provides more options for the printer, customers, and the business, allowing for an expansion of services and skills in both screen printing and graphic designing.

What software does the video recommend for preparing artwork for screen printing?

-The video recommends using CorelDRAW for preparing the artwork, converting it into bitmaps, and then into halftones.

What are the settings used for converting the image into halftones in the video?

-The settings used are 15 for cyan, 75 for magenta, 90 for yellow, and 45 for black, with a max dot ratio of three.

Why should the image be made lighter before printing according to the video?

-The image should be made lighter before printing because the colors tend to get darker during the screen printing process.

What adjustments did the video suggest for burning the screens?

-The video suggests using a mesh of 305 and lowering the burning temperature and time. It also recommends curing the screen twice on the back and once on the front, followed by scraping for an even layer of emulsion.

Why are processed inks recommended for CMYK screen printing in the video?

-Processed inks are recommended because they are soft for high mesh screens, mix well for accurate color matching, and are more concentrated, providing the exact colors needed for the print.

What is the recommended order for printing CMYK colors in the video?

-The recommended order is to start with the lightest color, yellow, followed by magenta, then cyan, and finally black.

Why is it better to print from the lightest to the darkest color in CMYK printing?

-Printing from the lightest to the darkest prevents the darker colors from seeping into the lighter ones' screens, which could alter the color and quality of the print.

What is the importance of design resolution in achieving high-quality prints according to the video?

-High-resolution designs ensure better print quality as they provide clearer images and more accurate color representation, which is crucial for screen printing.

Can CMYK screen printing be used on dark garments according to the video?

-Yes, CMYK screen printing can be used on dark garments, but it requires an underbase and some adjustments, which will be discussed in a separate video.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Introduzione alla stampa // Daniele Cogo

KEGIATAN P5 PERAKTEK MENYABLON | pkbm bina warga

CARA SABLON PLASTISOL | CARA SABLON KAOS MANUAL | CARA SABLON KAOS MANUAL MEMAKAI TINTA PLASTISOL

How to Burn Your Own Screens from Home: Screen Print Tutorial

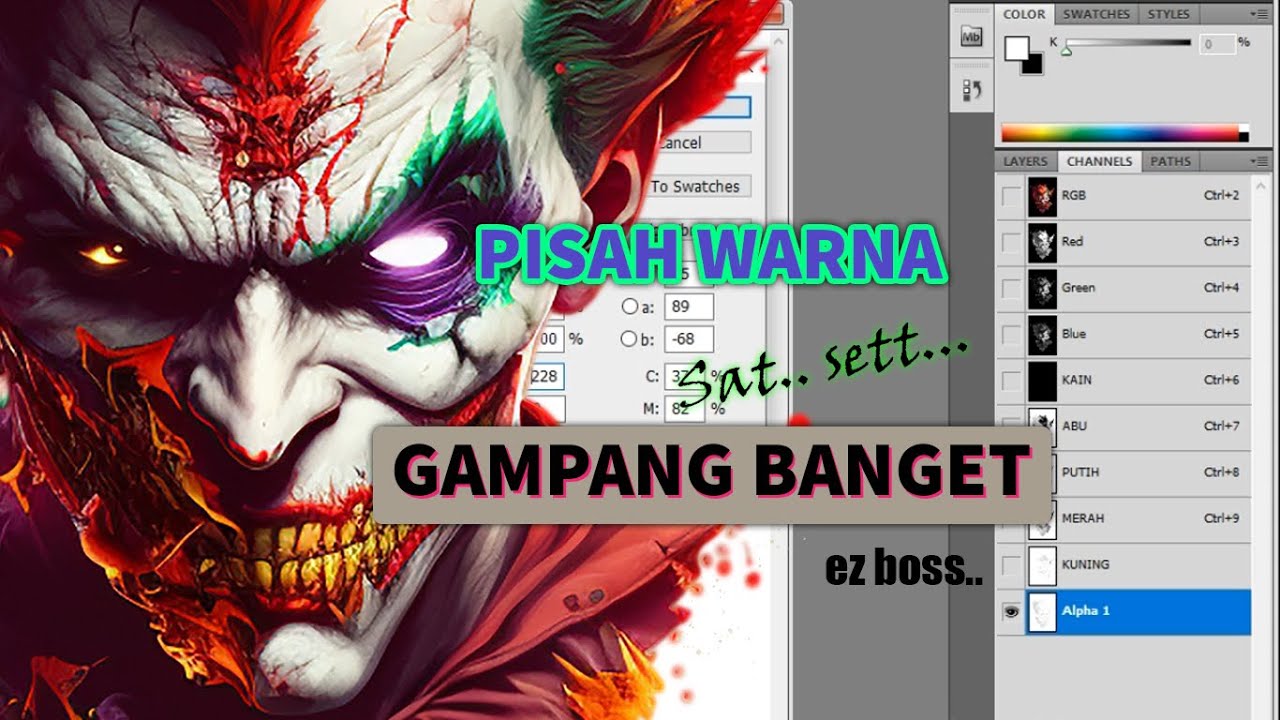

Cara Pisah Warna di Photoshop Untuk Film Sablon Pemula ( 6 warna 4 warna 2 warna )

Ujian Praktek English [Procedur Text] [How to Operate Printer to Print Document and Image]

5.0 / 5 (0 votes)