Which Splicing Device is Best? Push Ins Vs. Wago Vs. Wirenuts

Summary

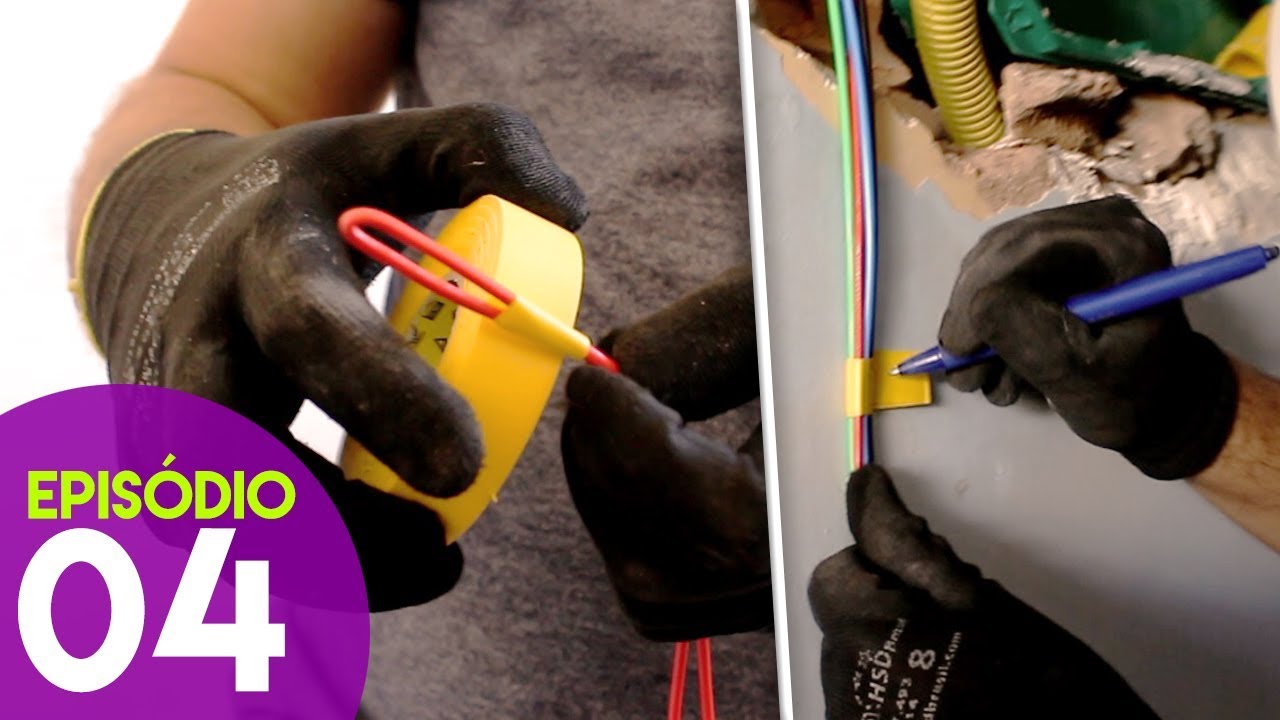

TLDRThis video script offers an in-depth review of common wire splicing devices, highlighting their pros and cons for DIY enthusiasts and electricians. The presenter discusses the Ideal push-and-connector, WAGO 221 connectors, and wire nuts, examining their ease of use, connection quality, and potential issues. The script provides practical advice on their application in various electrical scenarios, emphasizing the importance of correct installation for safety and performance.

Takeaways

- 🔌 The video discusses common mistakes made by DIY enthusiasts when connecting wires and using splicing devices.

- 🔧 The presenter reviews various splicing devices, providing insights on their appropriate use based on research and field feedback.

- 🏷 The push-and-connector made by Ideal is highlighted for its wide range of wire size compatibility (from number 20 to number 12 wire).

- 👍 The Ideal connector's ease of use and visibility through clear plastic is praised for ensuring proper wire seating.

- ⚠️ A drawback of the Ideal connector is the thin metal piece that may lead to higher resistance and heat generation.

- 💡 The presenter's personal experience and electricians' opinions suggest using the Ideal connector for low amperage situations like lighting.

- 🔄 The Waygo 221 is introduced as a versatile splicing device, capable of handling a wide range of wire sizes (from 24 gauge to number 12 wire).

- 🔗 The Waygo 221's lever system is commended for its secure wire connection and ease of wire removal for adjustments.

- 🔥 A potential issue with the Waygo 221 is the possibility of overheating due to limited surface contact between wires, causing varying opinions among electricians.

- 🛠 The Wire Nut is the most commonly used splicing device in the United States, valued for its good connection and low resistance.

- 👁️ The Wire Nut's lack of visibility under the nut is a con, as it doesn't allow for easy verification of the connection quality.

- 🛑 The video concludes with a recommendation to choose between Wire Nuts and Waygo 221 based on the specific situation and DIY capabilities.

Q & A

What is the main focus of the video?

-The video focuses on discussing and evaluating different types of wire splicing devices, their advantages and disadvantages, and their appropriate use cases based on the presenter's research and field experience.

What are the common mistakes DIY-ers make when connecting wires?

-The video mentions that DIY-ers often make mistakes when using splicing devices, but the specific mistakes are not detailed in the provided transcript. The video aims to address these issues by reviewing various splicing devices.

What is the brand of the push and connector discussed in the video?

-The push and connector discussed in the video is made by Ideal.

What wire sizes can the Ideal push and connector handle?

-The Ideal push and connector can handle wire sizes ranging from number 20 wire all the way up to number 12 wire.

What is the advantage of the clear plastic in the Ideal push and connector?

-The clear plastic allows users to see inside the connector and verify that the wires are fully seated at the top of the connector, ensuring a proper connection.

What is a potential issue with the metal piece in the Ideal push and connector?

-The metal piece in the connector is relatively thin, which results in less surface contact between the wires, leading to higher resistance and more heat generation.

What is the Way Go 221 and how does it work?

-The Way Go 221 is a type of splicing device that works by lifting levers to open holes for wire insertion. Once the wires are in place, the levers are flipped down to clamp the wires securely.

What is the strip gauge on the Way Go 221 used for?

-The strip gauge on the Way Go 221 indicates the exact amount of insulation to strip off the wiring to ensure a good connection.

What is a potential drawback of the Way Go 221 mentioned in the video?

-A potential drawback is that if the device is not properly installed and gets caught on wires or the box, it can accidentally flip open a lever, leading to a loose wire connection.

What is the wire nut and how does it provide a connection between wires?

-The wire nut is a commonly used splicing device in the United States. It has a metal coil inside that provides a good connection between wires and helps to hold the wire nut and wires together.

What is the advantage of using wire nuts in terms of resistance and heat?

-Wire nuts provide a large surface contact area between the wires, which results in lower resistance and less heat generation compared to some other splicing devices.

What is a potential issue with wire nuts in terms of installation?

-Wire nuts are not as DIY-friendly because users cannot see the connection underneath them. If not installed correctly, wires may fall out, leading to potential issues.

What is the recommendation for using Wago connectors in boxes?

-When installing Wago connectors in boxes, it is recommended to place your thumb across the levers to ensure they do not get caught on wires or the box, preventing the levers from flipping open accidentally.

In what types of boxes does the presenter usually use wire nuts?

-The presenter typically uses wire nuts in junction boxes, receptacle boxes, and other similar applications, but not in the places where other devices are more suitable.

What is the presenter's opinion on the future of the Way Go 221 in the United States?

-The presenter believes that the Way Go 221 will continue to gain popularity in the United States as they innovate and upgrade the devices, and as more people become aware of their existence.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)