Heat Transfer (27) - Heat transfer in internal flows in tubes

Summary

TLDRThis script discusses the transition from studying external flow over surfaces to internal flow within tubes and pipes, focusing on fluid dynamics and heat transfer. It explains the development of velocity and temperature boundary layers, leading to fully developed regions, and introduces two common heat transfer scenarios: constant wall heat flux and constant surface temperature. The importance of understanding flow patterns for engineering applications, such as in radiators and heat exchangers, is highlighted, along with the calculation of mean temperature and Reynolds number.

Takeaways

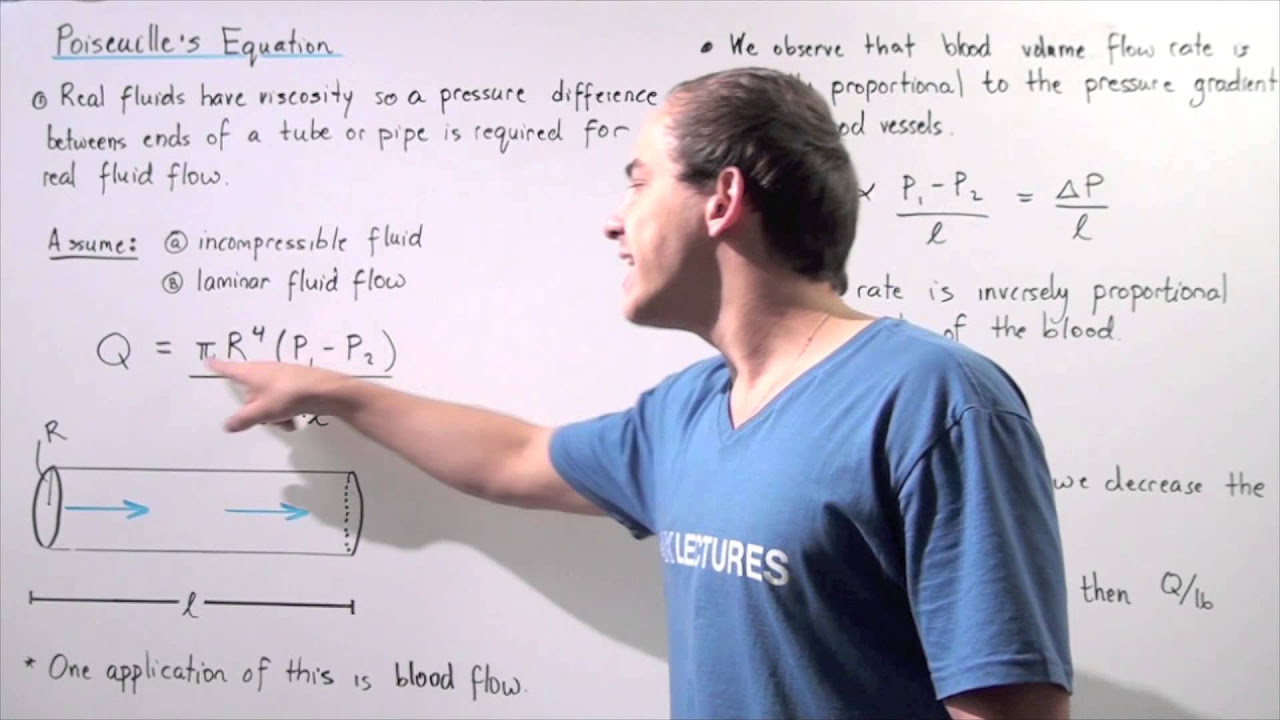

- 📚 The lecture transitions from Chapter 7, which focused on flow over external surfaces, to Chapter 8, which discusses internal flow within tubes, pipes, and cylinders.

- 🔍 The flow inside a circular tube is characterized by a uniform velocity at the entrance, with a boundary layer that thickens until it meets at the center line at a distance called x subscript FD (fully developed).

- 🌡️ In the context of heat transfer, the tube surface is assumed to be held at a constant temperature, while the fluid enters at a uniform inlet temperature, leading to the development of a thermal boundary layer.

- 🔥 Two distinct conditions for heat transfer in tubes are presented: constant wall heat flux and constant surface temperature, each resulting in different temperature profiles along the tube.

- ⚖️ The mean temperature of the fluid (Tm) is defined and calculated by integrating the product of the fluid properties across the tube's cross-sectional area.

- 🔑 The mean temperature (Tm) is crucial for determining the heat transfer rate in the tube, as it appears in the heat transfer equation alongside the surface temperature.

- 🔍 The concept of 'x fully developed' is introduced, which is the distance required for the flow to become fully developed after entering the tube, differing for velocity and temperature.

- 🌀 The Reynolds number is pivotal for determining whether the flow is laminar or turbulent, influencing the calculation of x fully developed and the nature of the flow and heat transfer.

- 🔢 The script emphasizes the practical importance of understanding flow patterns in engineering applications, such as in the design of heat exchangers and radiators.

- 🌡️ The temperature variation with distance in the tube is linear for constant wall heat flux and exponential for constant surface temperature, highlighting the different thermal behaviors.

- 💡 The lecture also touches on real-world applications, such as condensers in thermal systems and solar collectors, where the concepts of constant surface temperature and constant wall heat flux are relevant.

Q & A

What is the main focus of Chapter 8 in the transcript?

-Chapter 8 focuses on flow inside tubes, pipes, and cylinders, specifically addressing internal flows and the associated heat transfer.

What is the significance of the term 'fully developed' in the context of fluid flow?

-The term 'fully developed' refers to the point in the flow where the velocity boundary layers have grown and met at the center line of the tube, resulting in a parabolic velocity profile for laminar flow. Beyond this point, the flow is considered to be in the fully developed region.

What does the subscript 'M' stand for in the term 'u sub M'?

-In the term 'u sub M', the subscript 'M' stands for 'mean', indicating the mean velocity of the fluid flow inside the tube.

How does the temperature profile change as the fluid moves through the tube in a constant wall temperature scenario?

-In a constant wall temperature scenario, the temperature profile starts off non-uniform near the entrance of the tube, but as the fluid moves further down the tube, the profile becomes flatter until it eventually becomes totally flat, indicating that the fluid temperature has equilibrated across the cross-section to match the tube surface temperature.

What is the difference between the fully developed distance for velocity and the fully developed distance for temperature?

-The fully developed distance for velocity (x subscript FD) is the point where the velocity profile becomes parabolic and does not change further downstream. The fully developed distance for temperature (x subscript FDT) is the point where the temperature profile becomes uniform across the tube's cross-section. These distances can be different, especially in laminar flow.

What are the two conditions that can occur in a tube with respect to heat transfer as mentioned in the transcript?

-The two conditions that can occur in a tube with respect to heat transfer are constant wall heat flux and constant surface temperature. These conditions are relevant for different engineering applications and affect how the temperature varies along the tube.

How is the mean temperature of a fluid defined in the context of heat transfer?

-The mean temperature (Tm) of a fluid is defined as the temperature that would result if the fluid in the tube at a certain location were to be mixed in a cup and then measured with a thermocouple after stirring, also known as the mixing cup temperature.

What is the importance of understanding the mean temperature in heat transfer calculations?

-The mean temperature is important because it is used in heat transfer equations to determine the heat transfer rate between the fluid and the tube surface. It is a key variable in calculating the convective heat transfer coefficient (h).

How does the Reynolds number differ when considering flow inside tubes as opposed to flow over external surfaces?

-For flow inside tubes, the Reynolds number is calculated using the mean velocity (UM), diameter (D), and dynamic viscosity (mu) of the fluid. In contrast, for flow over external surfaces like a flat plate, the Reynolds number is based on the freestream velocity (U infinity) and a characteristic length (l) such as the distance from the leading edge.

What are some real-world applications where constant wall heat flux and constant surface temperature conditions are relevant?

-Constant wall heat flux is relevant in applications like solar collectors where a uniform heat is applied to the fluid. Constant surface temperature is applicable in condensers where the tube surface temperature is maintained at the saturation temperature of the condensing steam.

How does the fully developed distance for velocity and temperature vary with the Reynolds number?

-For laminar flow, the fully developed distance for velocity is approximately 0.05 times the Reynolds number times the diameter, while for turbulent flow, a 'magic number' of 10 times the diameter is used for both velocity and temperature due to the highly mixed nature of turbulent flow.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)