What to specify in a chemical warehouse design

Summary

TLDRIn this video, Mike Brody walks viewers through key considerations for designing a chemical storage warehouse. He covers essential aspects like properly segregating chemicals, choosing the right container and racking systems, fire suppression and temperature control, and the importance of safety features like emergency exits and safety showers. The video also highlights the role of ventilation, secondary containment, and specific building construction requirements to ensure safe storage. Brody emphasizes using guidance such as HSG71 and outlines different systems and materials for controlling risks when dealing with hazardous substances in bulk storage.

Takeaways

- 😀 Consider the type of chemicals to be stored and ensure proper segregation using HSG71 guidelines.

- 😀 Choose the appropriate container size for storage, such as small containers (25L or 5L) or large ones like 205L drums.

- 😀 Use secondary containment strategies, such as separation distances or bund segregations, to safely store hazardous chemicals.

- 😀 Ensure the warehouse construction meets the required safety standards, including fire-rated materials, insulation, and ventilation.

- 😀 Install a perimeter bund around the store to contain fire water runoff and weatherproof the warehouse.

- 😀 Plan for emergency exit routes within the warehouse to ensure safe evacuation during a fire or emergency.

- 😀 Consider temperature control systems to prevent issues like frost buildup or maintain strict temperature ranges (+/- 2°C).

- 😀 Use fire suppression systems such as foam, gas, or water sprinkler systems depending on the specific needs of your warehouse.

- 😀 Install safety features like tank showers with large drench capacities for emergency decontamination.

- 😀 Apply specialized floor coatings suited to the chemicals being stored, including anti-static, anti-corrosion, or anti-slip options.

- 😀 Use proper ventilation, either through natural vents or forced ventilation with ATEX fans, to manage chemical vapors in the warehouse.

Q & A

What is the first thing to consider when designing a chemical storage warehouse?

-The first thing to consider is the type of chemicals to be stored and how to segregate them properly, according to guidelines such as HSG71 for the safe storage of hazardous substances.

What does HSG71 guidance provide for chemical storage design?

-HSG71 provides segregation guidelines for hazardous substances, helping determine safe distances or bunds between chemicals to prevent dangerous reactions.

How should small containers like 25-liter drums be stored in a chemical warehouse?

-Small containers like 25-liter drums are best stored on small container shelving, which is specifically designed to hold these types of containers securely.

What is the recommended storage option for larger chemical containers like 205-liter drums?

-Larger containers, such as 205-liter drums or palletized boxes, should be stored using pallet racking, which is ideal for these types of bulk containers.

Why is secondary containment important in a chemical storage warehouse?

-Secondary containment is crucial to contain any potential chemical leaks or spills. It can be achieved through separation distances or physical bunds that keep chemicals properly segregated.

What construction considerations should be taken into account when designing a chemical warehouse?

-When designing a chemical warehouse, it's important to consider whether the building needs fire-rated construction, insulation for thermal properties, or natural ventilation for air circulation.

What role does the perimeter bund play in warehouse design?

-The perimeter bund serves two main purposes: it contains foam fire suppression water runoff to manage safety and acts as a weatherproof barrier to prevent rain from entering the warehouse.

Why are emergency exit routes important in chemical warehouses?

-Emergency exit routes are essential to ensure safe evacuation in case of emergencies, like a fire, particularly when workers need to escape from further inside the warehouse.

What are the options for temperature control inside a chemical warehouse?

-Temperature control can be achieved through static heating to prevent frost buildup or through more precise systems with overhead air cooling fans that maintain a temperature within a tight range, typically +/- 2°C.

What fire suppression systems are used in chemical storage warehouses?

-Chemical storage warehouses often use foam fire suppression systems, where water and foam are mixed and pumped at high pressure to fill the warehouse and extinguish fires.

What safety features are essential for chemical warehouses storing hazardous materials?

-Safety features include tank showers for emergency drenching, proper floor coatings (anti-static, anti-corrosion, or anti-slip depending on the chemicals), and ventilation systems, including ATEX fans for dealing with flammable vapors.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Optimizing Your Space: A Step-by-Step Guide to Designing an Efficient Warehouse Layout

Pewarnaan Graf (Graph Coloring) PART 2 | Algoritma Welch Powell & Contoh kasus penyimpanan zat kimia

Different Types of Warehouse Layouts

Struktur Kayu Vid06 Perencanaan Batang Tarik Part3

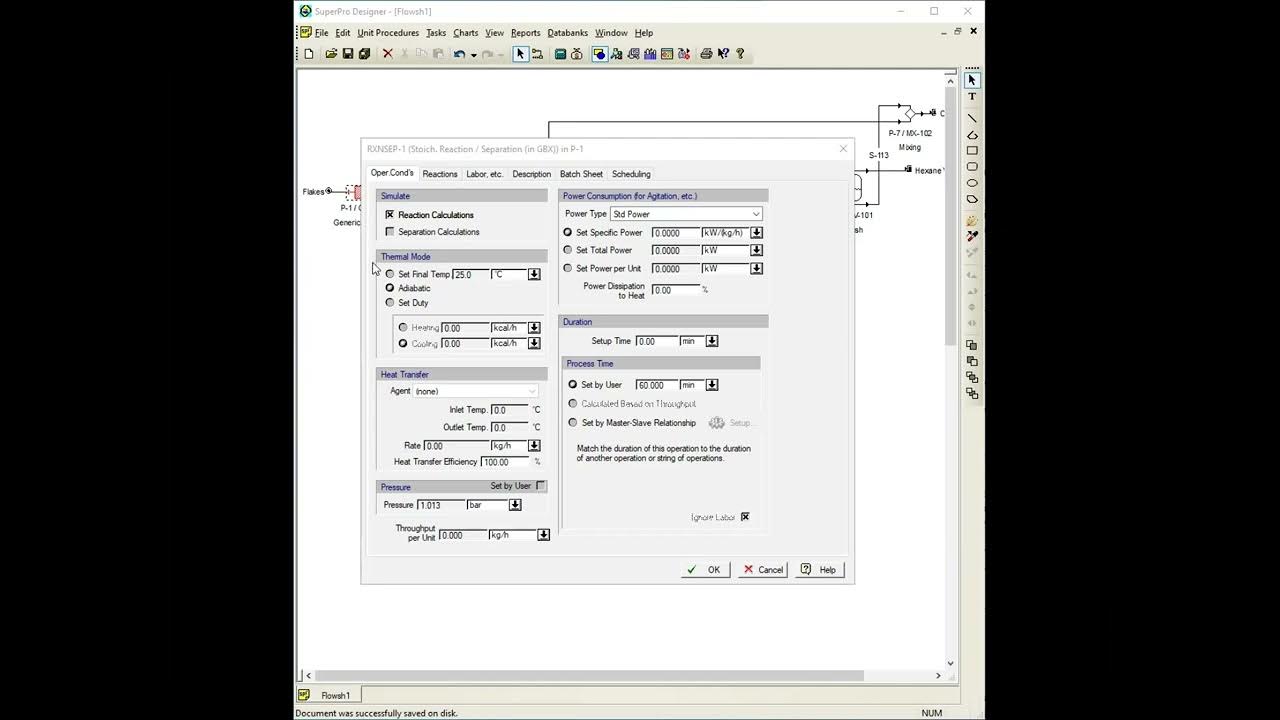

Extraction on SuperPro Designer

FortiGate 60F HA Cluster Build

5.0 / 5 (0 votes)