Beacon Calibration

Summary

TLDRBrad Xanders from Subside Electronics walks technicians through proper calibration of TK series trackers to Subside beacons. He emphasizes crucial pre-checks: install the beacon in its housing, perform calibration at least 30 ft from metal or the drill, avoid calibrating over utilities or concrete with rebar, and remove metal tape measures. He explains two calibration methods—connected (Bluetooth to configurable beacon; automatically calibrates both frequencies) and unconnected (non-configurable beacon; frequencies set manually). Measure a precise 10 ft (305 cm) center-to-center for calibration, verify while inside the calibration screen at 5T and 15T marks, and contact local dealers or product support with questions.

Takeaways

- 😀 Ensure the beacon is installed in the housing before calibrating the tracker to avoid inaccurate depth estimates.

- 😀 Always set up the calibration area at least 30 feet away from metal objects (vehicles, trailers, drills) to minimize interference.

- 😀 Do not calibrate the tracker with the housing still on the drill; ensure it's removed before calibration.

- 😀 Avoid calibrating over utilities or power lines; use a clean, grassy area, not concrete with rebar, to avoid calibration issues.

- 😀 Two methods for calibration: connected calibration (via Bluetooth) for automatic frequency adjustments, and unconnected calibration for manual frequency setup.

- 😀 During connected calibration, the tracker automatically calibrates both frequencies to ensure accurate depth estimates during drilling.

- 😀 For unconnected calibration, manually calibrate each frequency one by one when using a non-configurable beacon.

- 😀 Always measure the proper 10-foot or 305 cm distance between the tracker and the beacon for accurate calibration.

- 😀 Remove any metal tape measures during calibration to avoid interference with the depth estimate.

- 😀 Verify calibration within the calibration screen and stay within the designated verification distances (5T or 15T) to ensure accurate depth readings.

- 😀 Mark calibration distances (5T, 15T) on the ground for easier verification, ensuring accuracy at different measurement points.

Q & A

What is the first step to ensure accurate calibration when arriving at a job site?

-The first step is to ensure that the beacon is properly installed into the beacon housing. Without this, the calibration could affect depth estimates.

Why is it important to be at least 30 feet away from metal objects during calibration?

-Being 30 feet away from metal objects like pickups, trailers, or the drill ensures that there is no interference from the metal, which could distort the calibration process.

What type of area should you choose for the calibration setup?

-Choose a clean, grassy area for calibration. Avoid concrete with rebar or areas with utilities like power lines to prevent interference and ensure accurate depth measurements.

What is the difference between connected and unconnected calibration?

-Connected calibration uses Bluetooth to link the tracker with a configurable beacon, automatically calibrating both frequencies. Unconnected calibration requires manual calibration of each frequency to a non-configurable beacon.

How do you measure the proper distance for calibration?

-You should measure 10 feet or 305 cm from the center of the beacon housing to the center of the tracker or the antenna/pod. Ensure you are using a non-metallic tape to avoid interference.

What is the purpose of removing the tape during calibration?

-Removing the tape is important because metal tapes can interfere with depth estimates, potentially distorting the calibration results.

How can you tell if your tracker is connected via Bluetooth during calibration?

-The tracker screen will display a Bluetooth icon in the bottom menu bar when it's connected to the beacon, allowing for a connected calibration.

What frequencies are calibrated during the process, and why is this important?

-The process calibrates two frequencies, such as 12 kHz and 29 kHz, to ensure accurate depth estimates while drilling at both frequencies.

Why is it important to stay within the calibration screen while verifying the calibration?

-Staying within the calibration screen ensures that depth estimates are accurate. If you move to the walkover screen or outside the calibration range, the depth estimates could be off by 2.5 inches.

How can you verify calibration effectively at different distances?

-You can mark the ground at 5-foot and 15-foot intervals and verify calibration by placing the tracker at these marks to check accuracy at those distances.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Feeling lost, lazy, uninterested, and depressed after spiritual awakening (What to do?)

The Signs That You're Experiencing Sugar Withdrawal

Side Effects of Finasteride

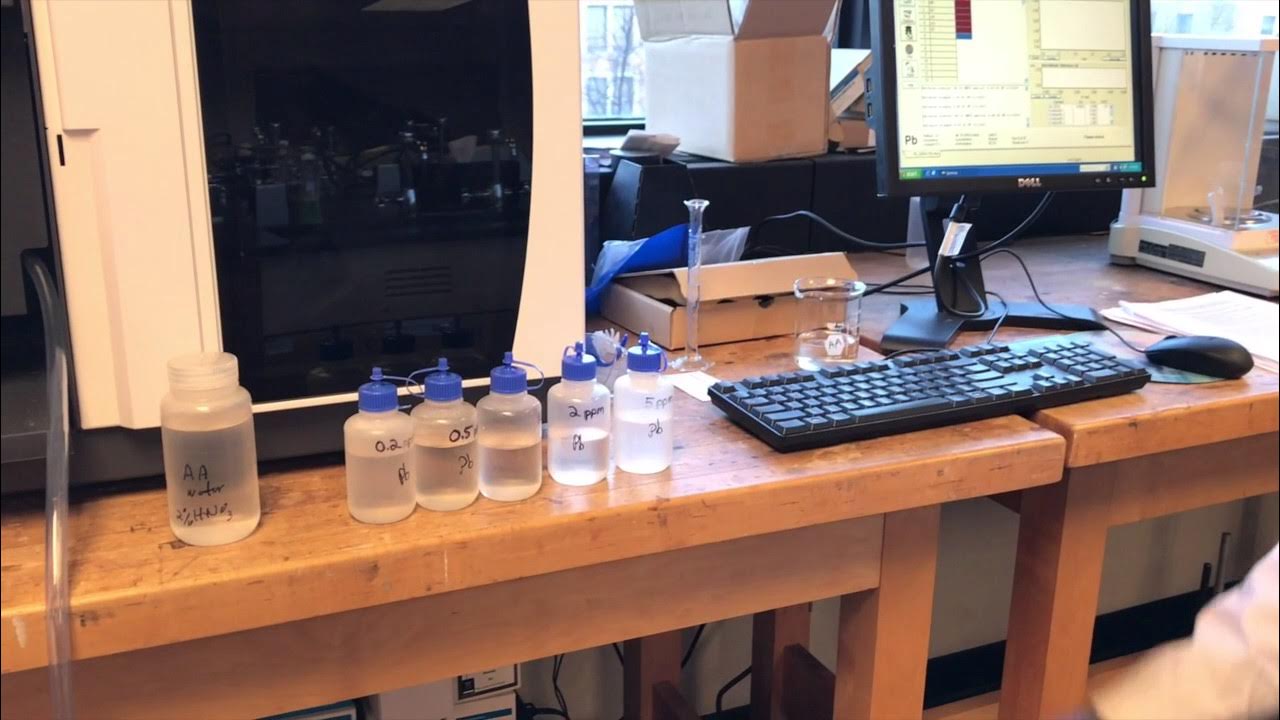

Atomic Absorption Spectroscopy Part 2

Ferrugem, Sorriso Maroto - Apaguei Pra Todos (Ferrugem 10 Anos - Ao Vivo)

PEMELIHARAAN PADA ALAT RADIOLOGI KONVENSIONAL DIGITAL RADIOGRAFI

5.0 / 5 (0 votes)