Downstream processing of mycoprotein

Summary

TLDRThis video explores the downstream processing of microprotein, a fungal-based meat substitute produced from Fusarium venenatum. The presenter, an expert in bioreactor engineering, explains how continuous fermentation in airlift reactors generates high-protein fungal biomass. Key downstream steps include reducing RNA content through heat treatment, centrifuging to harvest biomass, and optimizing texture via freezing or gelling agents. Unlike recombinant protein production, this process is relatively simple, with cost mainly driven by the carbon source. The video also highlights challenges such as mutations, reactor control, and safety, while touching on innovations like alternative carbon sources and global startups aiming to improve sustainability and scalability.

Takeaways

- 😀 Microprotein is a fungal-based protein used as a meat substitute, produced by Fusarium venenatum.

- 😀 The production process uses an airlift reactor, which is scalable, efficient, and particularly suited for large-scale production.

- 😀 One challenge in microprotein production is the high cost of glucose syrup, the primary carbon source used for fermentation.

- 😀 Safety concerns in the production of microprotein include microtoxins and nucleic acid levels that can lead to health issues like gout.

- 😀 Continuous culture systems are used in bioreactors, but the process is limited to about six weeks due to the occurrence of mutations in the fungus after extended periods.

- 😀 Downstream processing of microprotein is relatively simple, with no complex steps like chromatography, making it cost-effective compared to other biotechnological products.

- 😀 RNA content in the microprotein must be reduced to below 2% to prevent health issues like the formation of uric acid, which can cause gout.

- 😀 A heating process is used to reduce RNA content, which is efficient as it does not require changes in pH or medium composition, simplifying the downstream process.

- 😀 After fermentation, the fungal biomass is harvested through centrifugation, resulting in a solid content that can be processed into microprotein.

- 😀 The texture and consistency of microprotein are crucial for its use as a meat substitute. Freezing the product helps firm up its structure and improve its resemblance to meat.

- 😀 Despite the simplicity of the downstream process, decades of research have been invested in optimizing the production of microprotein, making it a safe and effective meat alternative.

Q & A

What is the main focus of the video?

-The video focuses on downstream processing of microprotein, which is used as a meat substitute, particularly in the production of Quorn, a fungus-derived protein.

Why is downstream processing of microprotein considered simpler than other biotechnological processes?

-The downstream processing of microprotein is simpler because it does not require complex steps like chromatography, which are common in processes such as recombinant protein production. The main steps involve centrifugation and RNA reduction, which are relatively straightforward.

What is the role of Fusarium venenatum in microprotein production?

-Fusarium venenatum is the fungus used to produce microprotein. It is selected for its high protein content and suitability as a safe food source, similar to how mushrooms are used in various cuisines.

What challenges are associated with the production of microprotein?

-Key challenges include the high cost of glucose syrup as a carbon source, the potential formation of mycotoxins, the risk of mutations in the fungal strain, and the need to manage RNA content to ensure it is safe for consumption.

Why is controlling RNA content crucial in microprotein production?

-RNA content is crucial because high levels of RNA can lead to the formation of uric acid in humans, which can cause health issues like gout. Therefore, microprotein must have an RNA content of less than 2%, ideally reduced to 1% for safety.

How is the RNA content reduced in microprotein during downstream processing?

-The RNA content is reduced by heating the microprotein to 68°C for 20 to 30 minutes, which decreases the RNA levels to below the recommended 2%, making it safe for consumption.

What is the purpose of centrifugation in the downstream processing of microprotein?

-Centrifugation is used to increase the solid content of the fungal biomass, allowing for the recovery of microprotein from the fermentation medium. This step helps concentrate the material for further processing.

What are the concerns related to mutations in the fungal strains used for microprotein production?

-Mutations in the fungal strains can lead to changes in the structure of the microprotein, making it less meat-like in texture. Managing these mutations is essential for maintaining the quality and consistency of the final product.

What technological innovations are being explored to improve microprotein production?

-Researchers are exploring ways to reduce mutations by knocking down specific genes in the fungal strains. Additionally, there is interest in using alternative carbon sources, such as natural sugars or waste materials, to lower production costs and improve sustainability.

How does the use of an airlift reactor benefit the production of microprotein?

-Airlift reactors offer high efficacy, are easier to scale up, and have lower shear levels, which are beneficial for the growth of fungal biomass. However, they are more complex and expensive to control compared to stirred-tank reactors.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

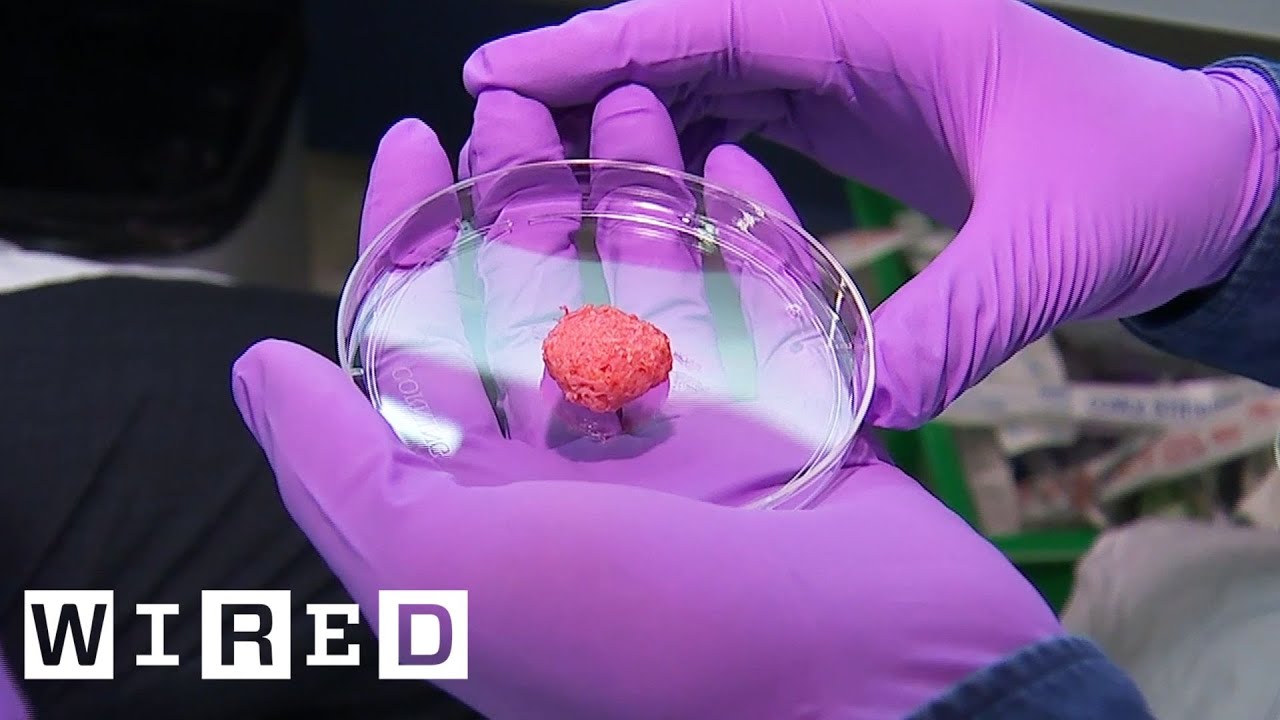

Inside the Quest to Make Lab Grown Meat | WIRED

Modern Chicken Meat Processing Factory | Chicken Factory

History of Food 4/5: Evolution of the Food Industry

Bahan Kimia dalam pengolahan daging_LabTP3_Fakultas Peternakan_Unpad

Bioeconomía como alternativa - ¿qué tan prometedores son los recursos renovables? | DW Documental

MATERI PRAKARYA KELAS IX (9) BAB IV PENGOLAHAN

5.0 / 5 (0 votes)