Milling Machine Basic Operation and Safety

Summary

TLDRThis video provides a thorough guide on basic mill safety and operation. It emphasizes the importance of proper PPE, including steel-toe boots, safety glasses, and ear protection. The instructor explains the three axes of a milling machine (X, Y, Z) and the use of the quill for depth control. Key operational steps are covered, such as powering the machine, adjusting RPMs, understanding gear selection, and verifying spindle rotation. The video also demonstrates how to safely install a cutting tool using the drawbar and stresses avoiding contact with rotating cutters. Practical tips on securing workpieces and preventing damage to the machine are highlighted for safe and effective milling.

Takeaways

- 🦺 Always wear proper PPE when operating a milling machine: steel-toe boots, safety glasses, and earplugs.

- 📏 Understand the three axes of the mill: X (side-to-side), Y (toward/away), and Z (up/down), plus the quill for additional vertical movement.

- 🛑 Use the emergency brake to quickly stop the spindle if necessary.

- ✋ Keep hands, sleeves, and any loose clothing away from rotating cutters to avoid injury.

- 🔌 Always verify spindle rotation direction: position '1' spins one way, position '2' spins the opposite way.

- ⚙️ Adjust variable spindle speed only while the spindle is running to maintain accuracy of the belt and pulleys.

- 🌀 Know your gear settings: high gear (inside ring) and low gear (outside ring) affect RPM and spindle direction.

- 🔧 Properly install cutting tools using the drawbar, aligning the taper and key, and tighten securely without leaving tools on the spindle.

- 🛠️ Use hand levers carefully to control X, Y, Z axes, and the quill, ensuring the workpiece is securely clamped.

- ⚠️ Always double-check RPM settings and spindle direction before starting any machining operation.

- 🔎 Inspect the machine and vise for previous damage or crashes, and operate cautiously to avoid further damage.

Q & A

What personal protective equipment (PPE) is recommended when operating a milling machine?

-Steel-toe boots, safety glasses, and earplugs are recommended. Additionally, keep sleeves and hands away from rotating cutters.

What are the primary axes on a milling machine and what movements do they control?

-The X-axis controls side-to-side movement, the Y-axis controls toward/away movement, and the Z-axis controls up-and-down movement. The quill also allows vertical adjustment for depth.

How can you quickly stop a milling machine in an emergency?

-By using the spindle brake located on the side of the machine, which stops the spindle immediately.

Why should you only adjust the spindle RPM while it is running?

-Adjusting the RPM while the spindle is off can stretch the belt and cause pulleys to lose their position, reducing the accuracy of the RPM.

How do high and low gears affect the milling machine spindle?

-High and low gears change the speed and direction of the spindle. High gear usually uses the inside ring for RPM readings, and low gear uses the outside ring. Gear selection also affects the spindle's clockwise or counterclockwise rotation.

What is the correct procedure for installing a cutting tool in a milling machine?

-Insert the tool or holder into the spindle, align the key with the spindle keyway, thread the drawbar onto the tool, and tighten it using a hammer. Ensure the tool is centered and secure before operation.

Why is it important to verify spindle direction before starting a cut?

-Cutters generally need the spindle to rotate clockwise for proper cutting. Incorrect spindle direction can damage the workpiece or the machine.

What should you be mindful of regarding tools left on the machine?

-Never leave tools, such as a hammer used to tighten the drawbar, on the machine, as the rotating spindle could hit them and cause damage or injury.

What are the key safety practices when operating the milling machine?

-Always wear PPE, keep hands and loose clothing away from rotating cutters, ensure the workpiece is secure, verify spindle direction and RPM, and use the spindle brake in emergencies.

What common mistakes occur in educational settings when using a milling machine?

-Crashing the milling cutter into the vise or machine is common, usually caused by lack of attention to spindle position, movement controls, or improper clamping of the workpiece.

How does one adjust the quill on a milling machine, and what is it used for?

-The quill is adjusted using a hand lever or feed control to move the spindle vertically, allowing precise control of the cutting depth.

What is the purpose of the key inside the spindle?

-The key ensures that the cutting tool or holder aligns correctly and rotates securely with the spindle, preventing slippage during operation.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

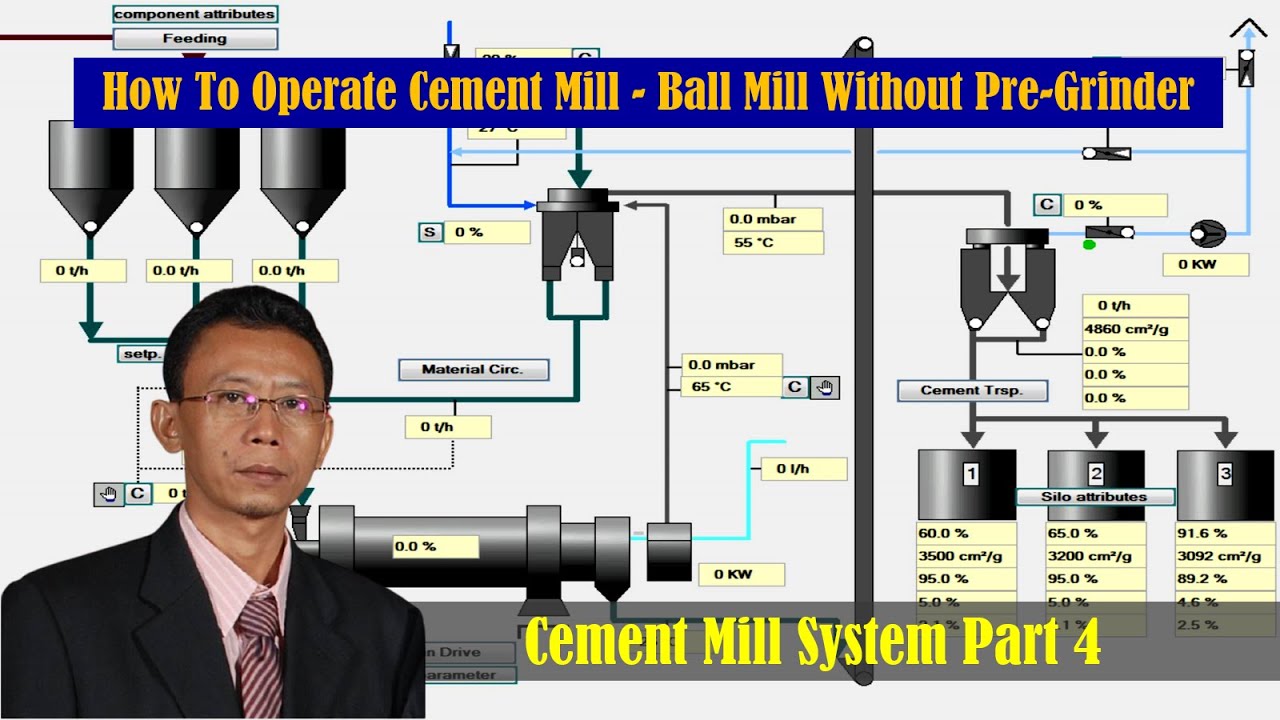

Cement Milling Process Ball Mill Operation Using Simulator _ English Version

Como trocar as hélices do drone agrícola de pulverização DJI Agras T20p e T40

Diesel Generator Training, Parts and components and working principle explain Power learning part 1

Stratix Industrial Switch - Preparing for Initial Use

Scissor Aerial Lift Training JLG ES

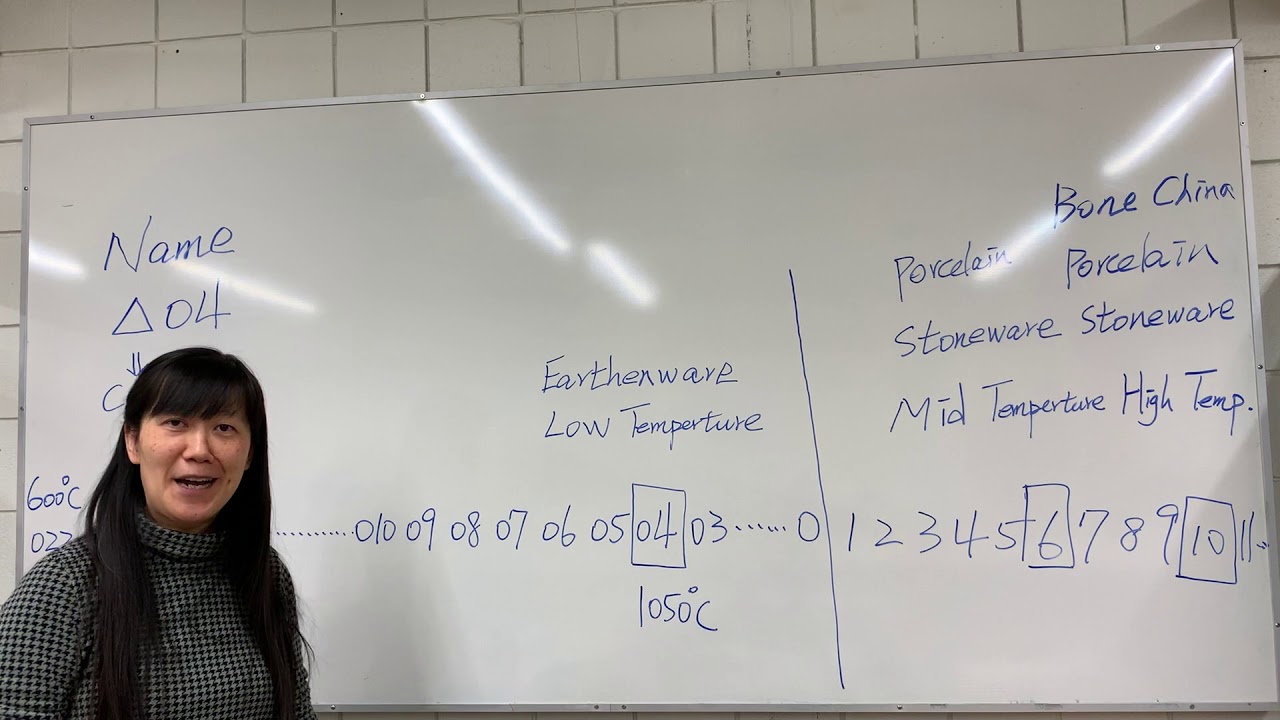

23.13 Name clay and tools, and Information for clay types and temperatures

5.0 / 5 (0 votes)