How Industrial Valves Are Made in Factory | Valve Manufacturing Process

Summary

TLDRThis video takes viewers behind the scenes of industrial valve manufacturing, revealing how these essential components control the flow of liquids and gases across industries. From initial design using CAD and computational fluid dynamics, to material selection, casting, precision CNC machining, and meticulous assembly, every step emphasizes accuracy and durability. Rigorous testing—including pressure, leak, ultrasonic, and X-ray inspections—ensures each valve meets strict operational standards. Finally, protective coatings and careful packaging prepare the valves for delivery. The video highlights the precision, expertise, and innovation involved in making valves, offering a fascinating look at the unsung heroes that keep modern industries running smoothly.

Takeaways

- 🔧 Industrial valves are essential components across multiple industries, controlling the flow of liquids and gases.

- 📐 Valve design starts with detailed CAD drawings that consider pressure, temperature, and flow requirements.

- 💻 Computational Fluid Dynamics (CFD) is used to simulate fluid flow and optimize valve efficiency and durability.

- 🛠️ Raw materials for valves typically include stainless steel, iron casting, or bronze, chosen based on application and corrosion resistance.

- 🏭 Valve body casting involves pouring molten metal into prefabricated molds to form intricate structures.

- ⚙️ CNC machining refines castings to extremely precise tolerances, often within a few microns, ensuring perfect fit and operation.

- 🌀 Drilling and threading processes prepare valves for assembly, ensuring leak-free and secure attachment of parts.

- 🧩 Valves are carefully assembled with lubricants, seals, and polymer components to guarantee smooth operation and prevent leaks.

- ✅ Rigorous testing, including high-pressure, ultrasonic, and X-ray inspections, ensures valve integrity and operational safety.

- 🎨 Surface treatments like sandblasting, painting, and special coatings protect valves from corrosion, wear, and high temperatures while providing identification markings.

- 📦 Proper packaging and, in some cases, vacuum sealing ensure valves are protected during transportation, especially for critical applications.

Q & A

What industries rely heavily on industrial valves?

-Industrial valves are crucial in nearly every industry, including oil and gas, food processing, chemical manufacturing, and water treatment, as they control the flow of liquids and gases.

What is the first step in the valve manufacturing process?

-The first step is the design process, where engineers develop detailed valve drawings using CAD tools, considering pressure, temperature, and flow requirements.

How is computational fluid dynamics (CFD) used in valve design?

-CFD is used to analyze fluid flow through the valve, optimizing its design for efficiency and durability by simulating operational conditions before manufacturing.

What factors influence the selection of materials for valve production?

-The choice of material, such as stainless steel, iron casting, or bronze, depends on the valve's application, with corrosion resistance and durability being key factors.

What is valve body casting, and why is it important?

-Valve body casting involves pouring molten metal into molds to form the valve's shape. It creates the intricate internal and external structures and forms the major shape of the valve.

What role does CNC machining play in valve manufacturing?

-CNC machining refines the castings to exact dimensions and surface tolerances, sometimes within a few microns, ensuring all moving parts fit perfectly for proper valve operation.

Why is threading and thread rolling critical in valve production?

-Threading ensures secure attachment of parts, preventing leaks, while thread rolling strengthens threads and increases resistance to fatigue, especially in high-precision valves.

How are valves assembled and sealed for operation?

-Workers precisely assemble the valve body, bonnet, stem, and internal parts. Lubricants and seals, including specialized polymer seals for high-pressure or chemical applications, are applied to prevent leaks.

What types of quality testing do valves undergo?

-Valves are tested for high-pressure performance, leaks, smooth operation, and overall integrity. Additional tests may include ultrasonic testing for internal faults and X-ray checks for casting integrity.

How are valves surface-treated before dispatch?

-Valves undergo sandblasting, painting, or special coatings to prevent corrosion, wear, and contamination. Complex coatings like ceramic or PTFE protect against high temperatures and aggressive chemicals.

Why is precise inspection important before shipping valves?

-Inspection ensures all dimensions, finishes, and markings meet standards, and proper packaging, such as crating or vacuum sealing, protects valves during transportation, especially for critical applications.

What makes valve manufacturing a process of high precision and expertise?

-From design and material selection to casting, CNC machining, assembly, testing, and coating, each step requires careful precision to ensure the valve performs reliably under demanding operational conditions.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

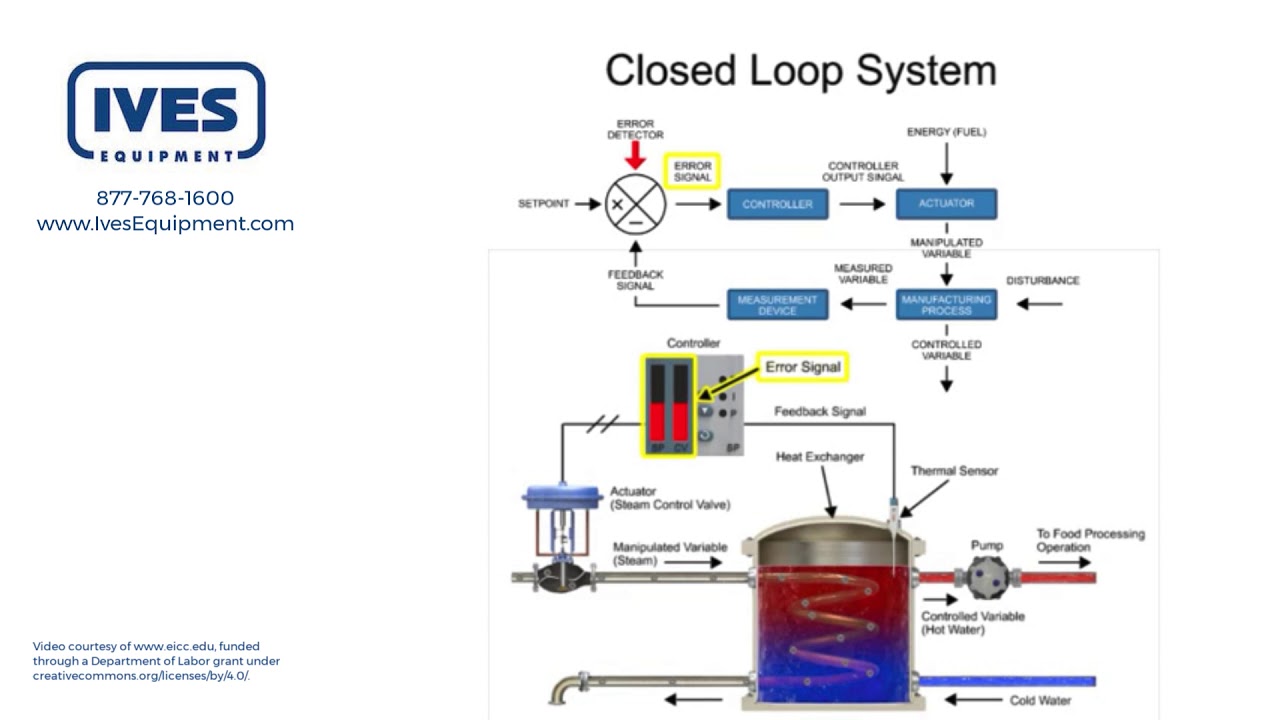

Regelkringen in productie- en procesinstallaties

Directional Control Valve Working Animation | 5/2 Solenoid Valve | Pneumatic Valve Symbols Explained

Introduction to a Closed Loop Control System

What is Mechatronics? Let's Get to Know the Basic Components and How They Work! Simple Tutorial E...

How Do Control Valve Actuators Work?

Flow-Tech: Industrial Control Valve Basics

5.0 / 5 (0 votes)