What is a Transmitter -Instrumentation Technician Course - Lesson 2

Summary

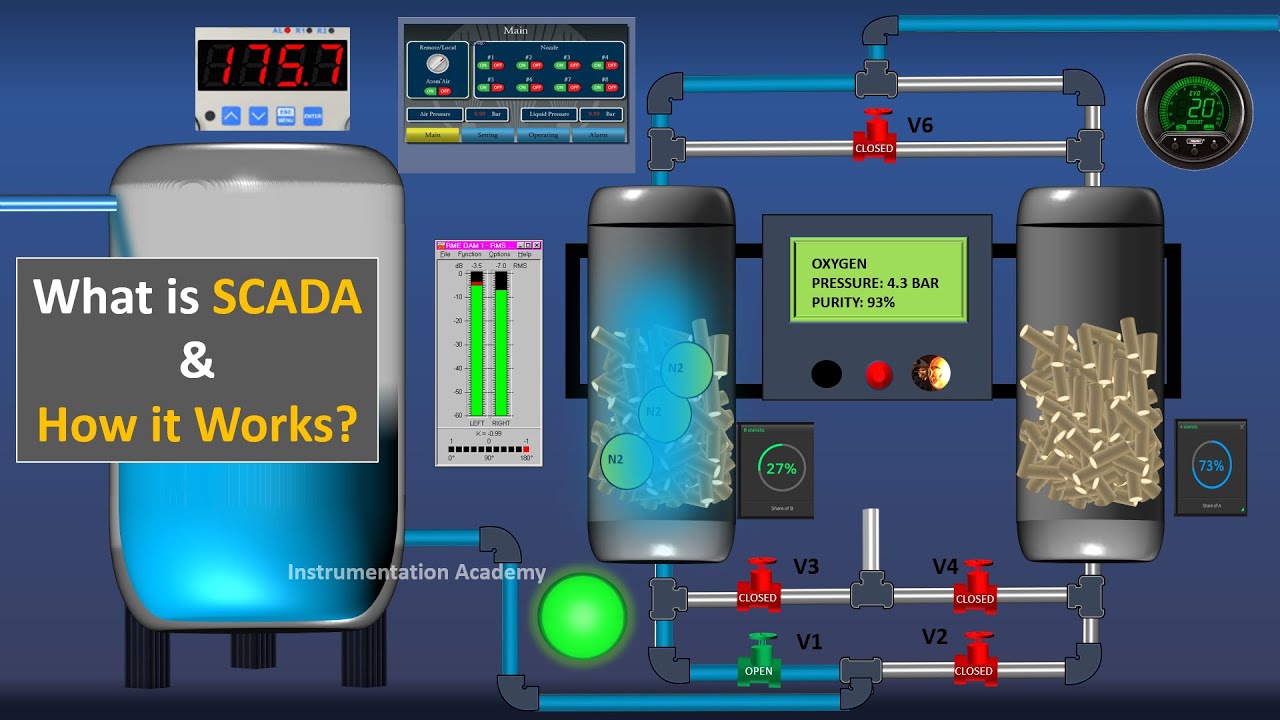

TLDRThis video delves into instrumentation control and the role of process variables in modern industrial systems. Building on a previous lesson, it explains how variables like pressure, temperature, flow, and level are used for process control, safety shutdowns, and operator monitoring. The video highlights how transmitters detect these variables and convert them into signals compatible with control systems, including pneumatic, electrical, and communication protocols such as 4-20 mA, RS-232, and HART. Through a practical example of a pressure transmitter, viewers learn how measurements are transmitted to PLCs and displayed on HMIs, providing both operational insight and fault detection. Future videos will explore specific transmitter types and their operating principles.

Takeaways

- 😀 Process variables are critical conditions of a plant that ensure safe and efficient operation, including pressure, level, temperature, and flow.

- 😀 Process variables can be used for process control, as inputs to maintain setpoints, or as triggers for safety shutdown systems.

- 😀 High Integrity Pressure Protection Systems (HIPPS) use process variables to prevent over-pressurization of vessels and pipes.

- 😀 Operators monitor process variables through HMIs (Human-Machine Interfaces) in control rooms or via local indicators like gauges and enunciators.

- 😀 Transmitters are devices that detect process variables and convert them into signals that control systems can interpret.

- 😀 Transmitters send signals to PLCs or controllers, allowing information to be processed and acted upon in industrial systems.

- 😀 Signal types from transmitters include pneumatic (3–15 psi), raw electrical (0–10V, 1–5V, 4–20 mA), and digital communication protocols (RS-232, RS-422, RS-485, TCP/IP, HART).

- 😀 Pneumatic transmitters are useful in hazardous areas or where electrical infrastructure is limited, as they do not pose ignition risks.

- 😀 The 4–20 mA signal standard allows detection of faults like broken cables, since zero pressure is represented by 4 mA, not 0 mA.

- 😀 Modern instrumentation often combines raw signals and communication protocols to allow both measurement and configuration using tools like HART communicators.

- 😀 Understanding how transmitters work and their role in control systems is fundamental to instrumentation and industrial process control.

Q & A

What are process variables and why are they important in industrial control systems?

-Process variables are the critical conditions of a process plant, such as pressure, level, temperature, and flow. They are important because they are essential for both operational efficiency and safety, ensuring the plant functions correctly and that unsafe conditions are avoided.

How are process variables used in process control loops?

-Process variables serve as inputs to control loops to maintain a desired setpoint. For example, they help regulate temperature in a heating system or control pressure in a vessel by providing feedback to the system to adjust its operation.

What role do process variables play in plant safety systems?

-Certain process variables act as initiators for shutdown systems. For instance, a high-integrity pressure protection system (HIPPS) will shut down equipment if pressure exceeds safe limits to prevent damage or hazardous situations.

How can operators monitor process variables?

-Operators can monitor process variables through control room interfaces like HMIs (Human Machine Interfaces) that display live data and generate alarms, or locally via devices such as pressure gauges or enunciator panels.

What devices are used to detect and transmit process variables?

-Transmitters are used to detect process variables and convert them into signals that a process control system, like a PLC, can understand. They essentially transform physical measurements into readable data for monitoring and control.

What are the main types of transmitter output signals?

-Transmitter outputs are broadly categorized into pneumatic signals, raw electrical signals (voltage or current), and digital communication protocols such as RS-232, RS-485, or TCP/IP. Pneumatic signals typically range from 3-15 psi, while electrical signals commonly use 4-20 mA or 1-5 V.

Why is a 4-20 mA current signal preferred over a 0-20 mA signal?

-Using 4-20 mA instead of 0-20 mA allows detection of wiring or transmitter faults. A reading below 4 mA indicates an issue, such as a broken cable, whereas a 0 mA signal could be confused with a zero process condition.

How does a typical pressure transmitter work with a 4-20 mA signal?

-The transmitter senses the pressure in a vessel and adjusts its internal impedance to vary the current. For example, 0 bar corresponds to 4 mA and 10 bar corresponds to 20 mA. This signal is sent to a PLC, which can then be displayed via SCADA or HMI for operator monitoring.

What advantages do pneumatic transmitters offer?

-Pneumatic transmitters are useful in areas without electrical infrastructure and in hazardous environments where electrical sparks must be avoided. They provide a safe method of transmitting signals using pressurized air instead of electricity.

What is HART protocol and how is it used in instrumentation?

-HART (Highway Addressable Remote Transducer) is a communication protocol that allows digital communication over an existing 4-20 mA analog signal. It is commonly used for configuring and interrogating transmitters with handheld communicators while maintaining the analog signal for control systems.

Why might different types of signals be present on the same plant site?

-Industrial plants evolve over many years, so equipment of varying ages may coexist. Older transmitters might use pneumatic signals, while newer systems use electrical or digital communication protocols, leading to a mix of signal types on the same site.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What Is Industrial Instrumentation? Start Here! 💡 Ep1

1. Introduction - Process Control Instrumentation -

Process control loop Basics - Instrumentation technician Course - Lesson 1

Konsep Dasar Fisika Instrumentasi 1

What is SCADA, How SCADA Works, Components, Architecture & Applications. SCADA Tutorial

02 - Process Control System

5.0 / 5 (0 votes)