FAI - Federal Aerospace Institute SafetyWire Demo

Summary

TLDRIn this instructional video, Brad McDonald, an instructor at the Toledo Public Schools Aviation Center, demonstrates the process of safety wiring bolts. He begins by preparing his safety wire pliers with silicone to prevent losing wire pieces. Brad carefully explains how to twist the wire around bolts, ensuring tightness and safety with seven turns per inch. He also shows how to manually adjust the wire to avoid gaps and achieve a clean, secure fit. The tutorial concludes with proper trimming and finishing techniques to avoid injuries from loose ends, ensuring a professional and safe safety wire job.

Takeaways

- 😀 Use silicone to fill the void in safety wire pliers to prevent losing small pieces of wire.

- 😀 Cutting the safety wire using a razor blade ensures it doesn't fall into places where it can cause harm, such as engine inlets.

- 😀 When safety wiring bolts, start by feeding the wire through the bolt head.

- 😀 Ensure the safety wire is tightly twisted with approximately seven turns per inch.

- 😀 Avoid gaps and loose wire by manually tightening the wire near the bolt head for a neat finish.

- 😀 Turn the safety wire pliers in the opposite direction when tightening around the second bolt to prevent wire from flipping over the bolt head.

- 😀 Ensure the wire is tight at both ends for a secure, professional finish.

- 😀 Clip any excess wire carefully so it doesn’t get lost or pose a risk to safety.

- 😀 Use a pigtail (small loop) on the end of the wire to prevent injury from sharp wire ends.

- 😀 A proper safety wire job ensures secure fastenings and eliminates safety hazards from loose components.

Q & A

What is the purpose of filling the safety wire pliers with silicone?

-Filling the safety wire pliers with silicone helps to catch any small wire pieces that may get cut off, preventing them from falling into dangerous areas such as engine inlets or tire puncture points.

Why does Brad use a razor blade after filling the pliers with silicone?

-Brad uses a razor blade to cut through the silicone in the center. This ensures that the small wire pieces cut off are securely trapped within the silicone, preventing them from being lost.

How many turns per inch should be made when twisting the safety wire?

-You should aim for about seven turns per inch when twisting the safety wire to ensure it is secure and tight.

What happens if there is a gap between the safety wire and the bolt head?

-If there is a gap between the safety wire and the bolt head, the wire will appear loose and sloppy. To correct this, you can manually give the wire one additional turn with the pliers, creating a tighter fit.

Why does Brad manually turn the wire when tightening it on the first bolt?

-Brad manually turns the wire to eliminate any slack, ensuring the wire sits tightly against the bolt head. This action helps to avoid the wire looking loose or sloppy.

Why does Brad twist the safety wire in the opposite direction on the second bolt?

-Twisting the safety wire in the opposite direction on the second bolt prevents the wire from flipping over the head of the bolt, which would make it less secure.

What is the purpose of the pigtail on the clipped wire?

-The pigtail is added to ensure that the clipped wire does not have any sharp edges sticking out. This makes it safer for anyone working on the engine or nearby parts.

How does Brad prevent the safety wire from falling when clipping off the excess?

-Brad prevents the safety wire from falling by catching it inside the silicone, which holds onto any loose pieces that may fall off during the clipping process.

What is the main benefit of using the silicone-filled pliers method?

-The main benefit is that it prevents small wire pieces from being lost and falling into dangerous or hard-to-reach areas, making the safety wiring process more organized and safer.

What should you do if the safety wire is too loose after twisting it?

-If the safety wire is too loose, manually turn the wire with the safety wire pliers to tighten it and ensure it sits securely against the bolt, improving the wire's effectiveness in keeping the bolt secure.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Aircraft Safety Wiring Basics | What Every A&P Needs to Know (How to lock wire)

Electrical Panel Enclosure | Baying Systems, Panel Compartments, Panel RAL Color, Lifting Eyebolts

AMANKAN Instalasi Listrik rumah anda dengan bahan2 ini..@selangtimbang

ATSEP for CNS/ATM infrastructure facilities

Centro de gravedad en aviones | Explicado en detalle

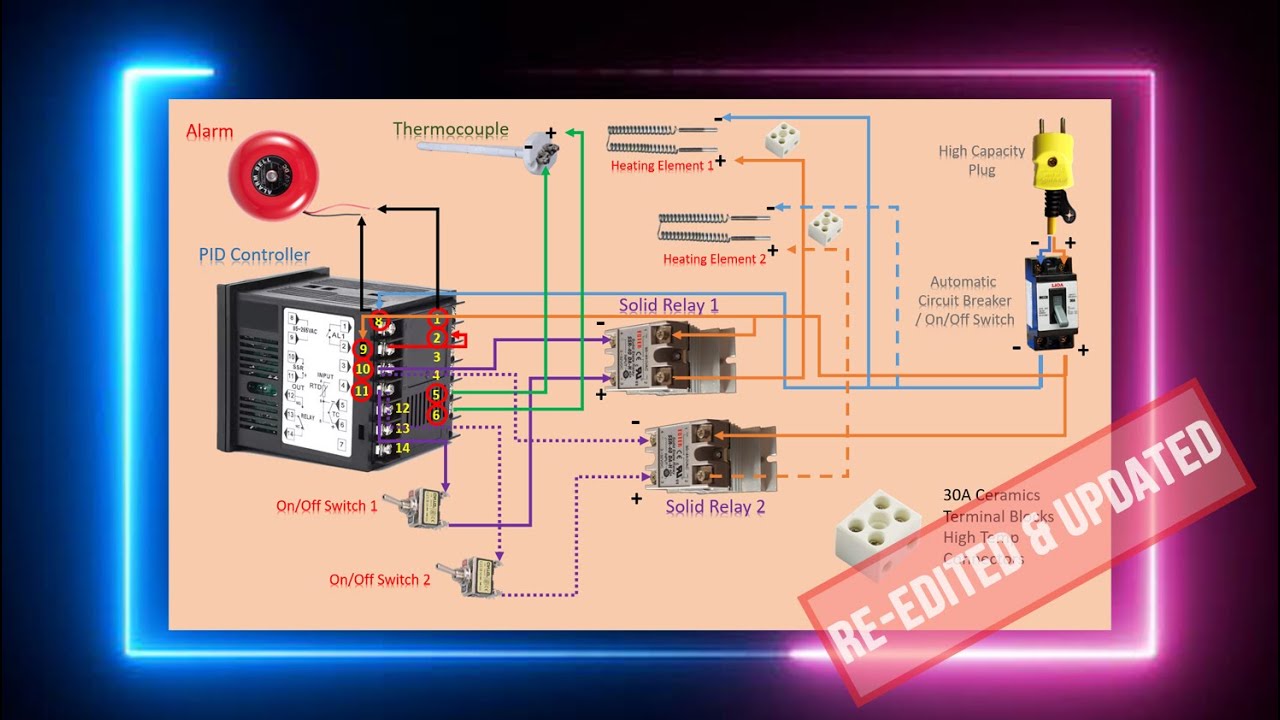

HOW TO WIRE PID FOR SINGLE OR MULTIPLE HEATING ELEMENTS | RE-EDITED & UPDATED

5.0 / 5 (0 votes)